Anisotropic insulating and heat-conducting composition and preparation method thereof

An insulating heat-conducting and anisotropic technology, which is applied in the field of anisotropic insulating and heat-conducting compositions and their preparation, can solve the problems of not paying attention to the physical properties of the cured product, complicated production methods of heat-conducting sheets, unfavorable large-scale continuous production, and the like. Conducive to large-scale continuous production, improved physical properties, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

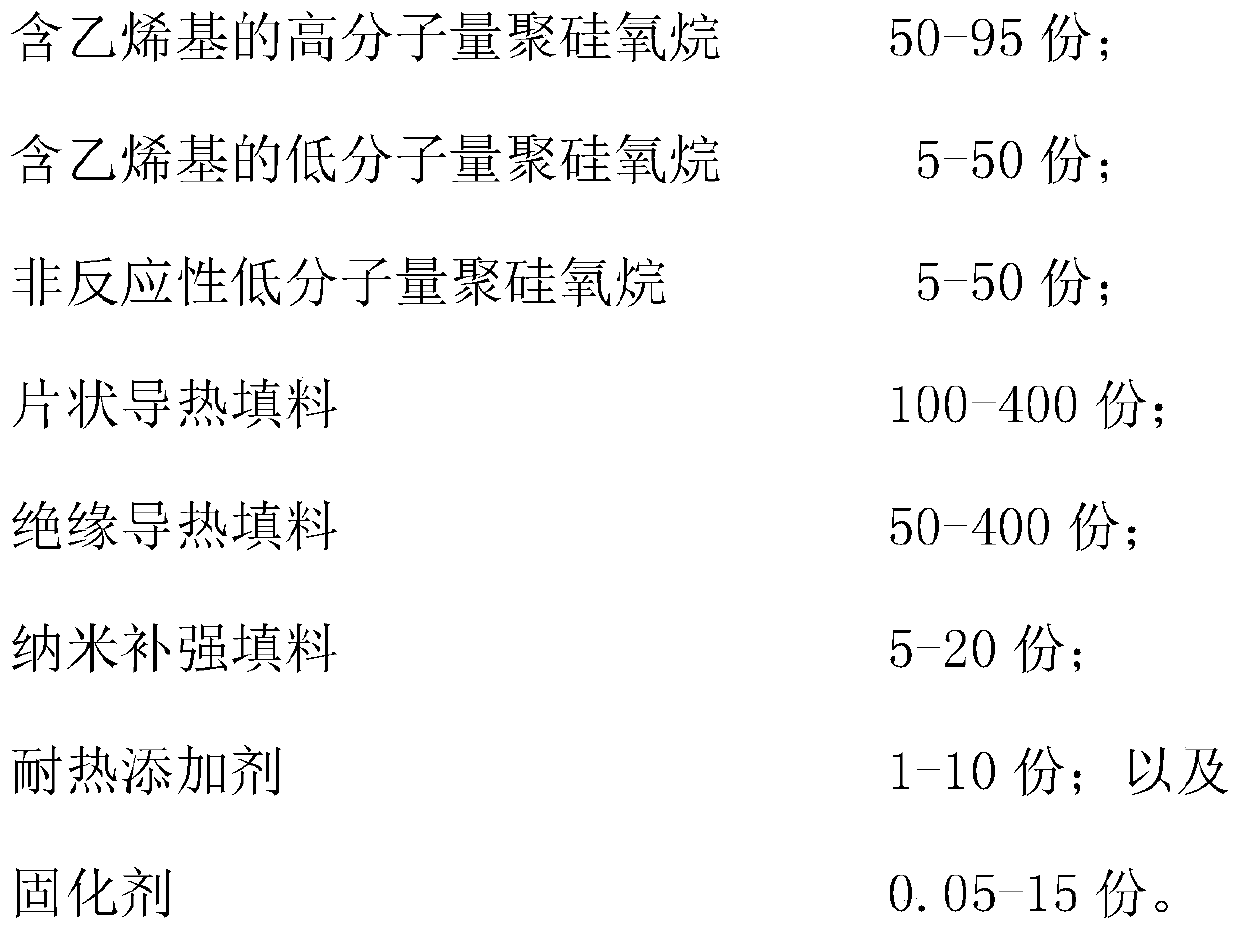

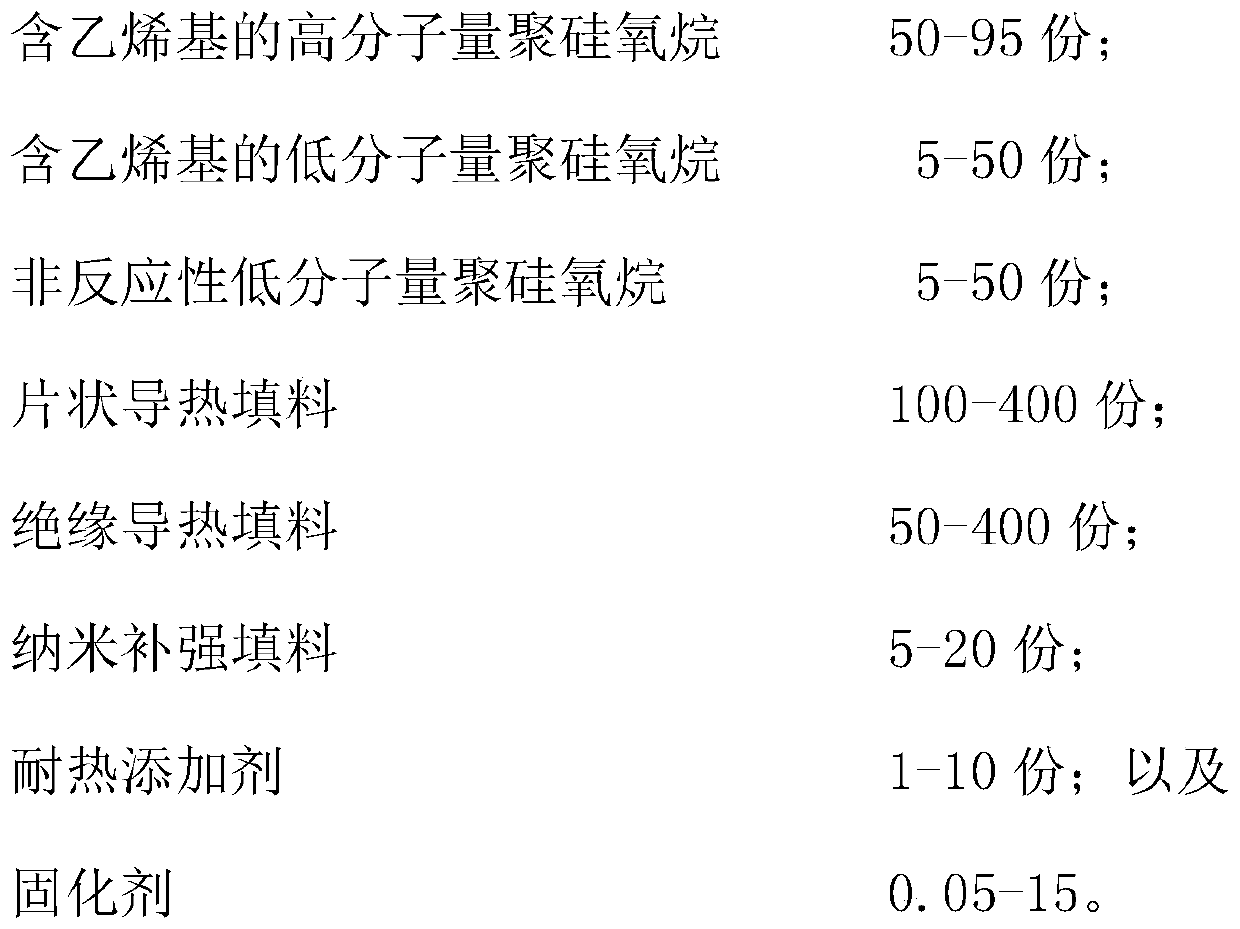

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the anisotropic insulating and heat-conducting composition of the present invention may comprise the following steps:

[0037] S1. Mix the raw materials in parts by mass to form a mixture.

[0038] S2, extruding the mixture into sheets through an extruder.

[0039] Wherein, the length of the extrusion chamber of the extruder is 0.5cm-50cm, preferably 2cm-10cm; the length of the extrusion chamber is less than 2cm and the degree of orientation is insufficient, and it is difficult to extrude if the length of the extrusion chamber is less than 2cm. The width of the extrusion cavity is 0.1mm-50mm. Preferably 1cm-5cm; if the width of the extrusion cavity is less than 1cm, the size of the finished product will be too small, and if it is greater than 5cm, it will be difficult to extrude a complete sheet. The thickness of the extrusion cavity is 0.1mm-10mm, preferably 0.3mm-2mm; if the thickness of the extrusion cavity is less than 0.3mm, it will make...

Embodiment 1

[0048] 600g of long-chain polydimethylsiloxane with an average molecular weight of 500,000, 200g of terminal vinyl dimethylsiloxane with an average molecular weight of 1000, 200g of polydimethylsiloxane with an average molecular weight of 1000 Add it into a 2L kneader, knead and stir for 5 minutes at room temperature, and then add 1000g of flake boron nitride powder with an average particle size of 25μm, 500g of spherical alumina powder with an average particle size of 3μm, and 500g of 2μm spherical alumina powder, 200g BET method specific surface area is 200m 2 / g of fumed silica, mixed at room temperature for 2 hours. After mixing and discharging, take out 400g and add 2g of long-chain polydimethylsiloxane mixture with an average molecular weight of 500,000 containing 50% 2,5-dimethyl-2,5-di-tert-butylperoxyhexane, Mix well on an open mill. The resulting mixture was extruded using a screw extruder into a sheet 0.6 mm thick, 30 mm wide, (die channel length 5 cm) 40 cm long....

Embodiment 2

[0050] 700g of long-chain polydimethylsiloxane with an average molecular weight of 500,000, 100g of terminal vinyl dimethylsiloxane with an average molecular weight of 5000, 200g of polydimethylsiloxane with an average molecular weight of 500, respectively Add it into a 2L kneader, knead and stir at room temperature for 5 minutes, then add 1000g flake boron nitride powder with an average particle size of 40μm, 500g spherical aluminum nitride powder with an average particle size of 3μm, and 300g average particle size Boron nitride powder with a diameter of 2μm, 200g of BET method has a specific surface area of 200m 2 / g of fumed silica, mixed at room temperature for 2 hours. After mixing and discharging, take out 400g and add 2g of long-chain polydimethylsiloxane mixture with an average molecular weight of 500,000 containing 50% 2,5-dimethyl-2,5-di-tert-butylperoxyhexane, Mix evenly on an open mill, and then extrude into a sheet with a thickness of 0.6 mm, a width of 30 mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com