Method for preparing long-branch chain polylactic resin by combination of function group reaction and linear enantiomer polylactic acid

A technology of long-chain branched polylactic acid and polylactic acid resin, which is applied in the field of preparation of long-chain branched polylactic acid resin by the combination of functional group reaction and linear enantiomer polylactic acid, can solve the problems of low production efficiency of long-chain branched polylactic acid, and achieve Significant branching effect, increased degree of long branching, and high melt strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

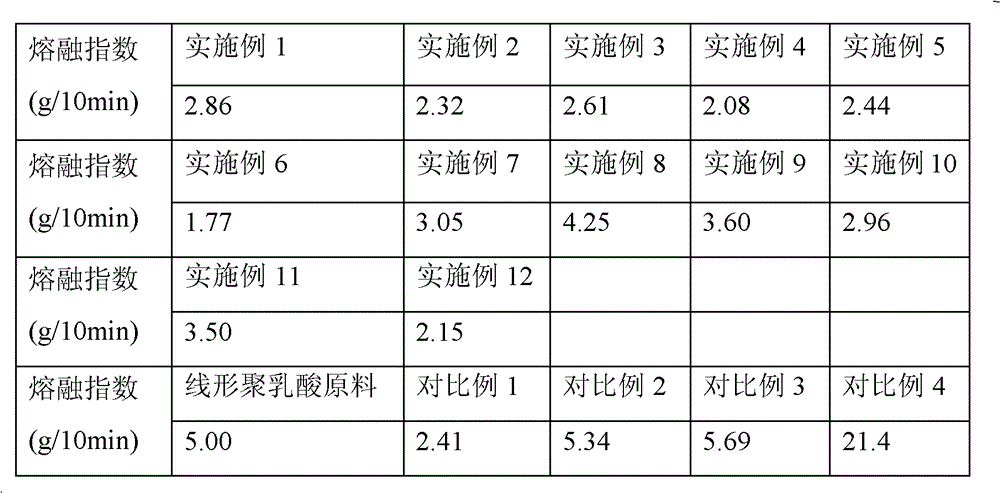

[0024]Functional group reaction combined with linear enantiomer polylactic acid to prepare long-chain branched polylactic acid Add 100 parts by weight of linear polylactic acid resin and 5.3 parts of linear enantiomer polylactic acid to an internal mixer at 250°C with a rotation speed of 20rpm, After it melted at constant temperature, add 0.16 parts of 1,3,5-trimethyl-2,4,6-tris(3,5-di-tert-butyl-4-hydroxybenzyl)benzene, 0.34 parts of N, N,N',N'-tetraglycidyl-4,4'diaminodiphenylmethane, mix for 2 minutes; then increase the internal mixer to 100rpm, melt blend until the reaction is complete, that is, stop after about 3.5 minutes , to produce long-chain branched polylactic acid. Table 1 shows the melt index (190° C., 2.16 kg load) of the obtained reaction product material measured according to the ASTM D1238 standard.

Embodiment 2

[0026] Synthesis of Long-chain Branched Polylactic Acid by Functional Group Reaction and Linear Enantiomer Polylactic Acid

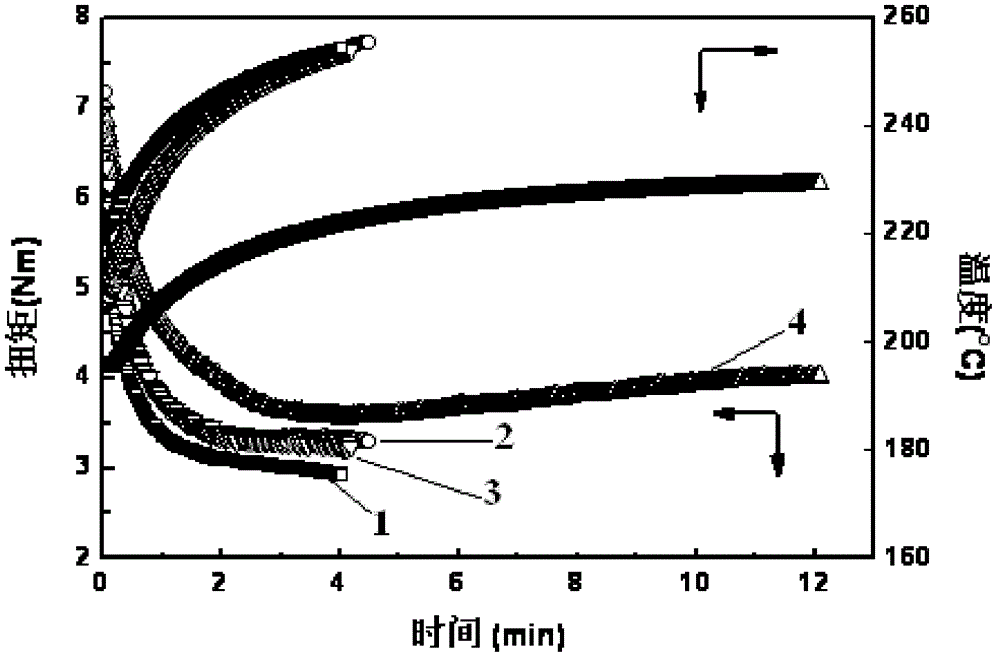

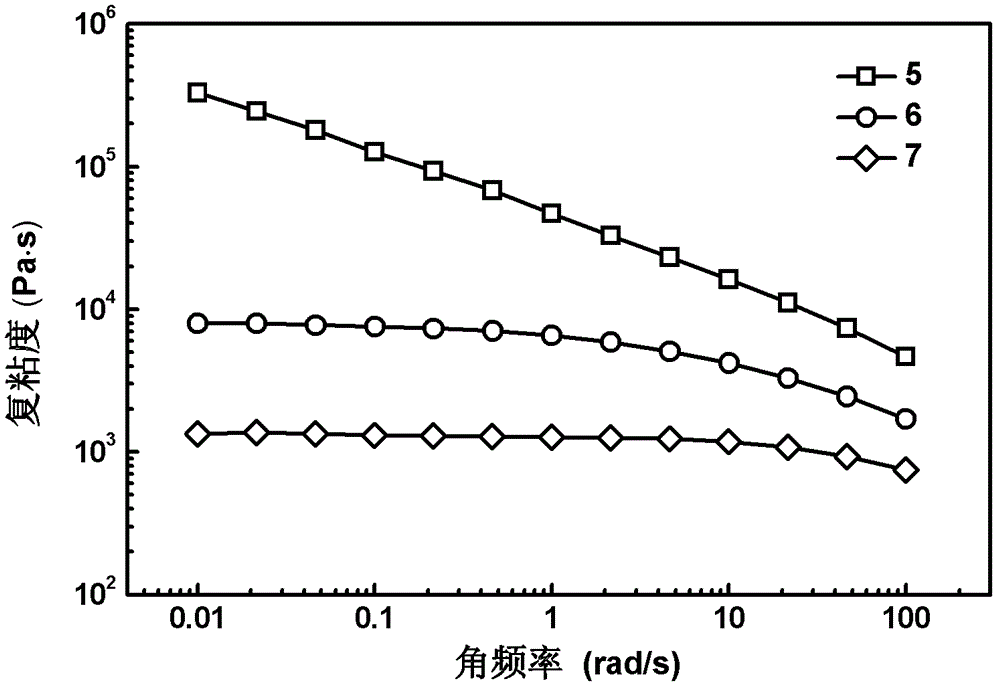

[0027] Add 100 parts by weight of linear polylactic acid resin and 11.1 parts of linear enantiomer polylactic acid to an internal mixer with a rotation speed of 20 rpm at 250 ° C, and add 0.17 parts of 1,3,5-trimethyl -2,4,6-tris(3,5-di-tert-butyl-4-hydroxybenzyl)benzene, 0.36 parts of N,N,N',N'-tetraglycidyl-4,4'di Aminodiphenylmethane, mixed for 2 minutes; then the internal mixer was raised to 100rpm, and blended until the reaction was completed, and stopped after about 3.5 minutes to obtain long-chain branched polylactic acid. The melt index test results are shown in Table 1. The torque and temperature curves in the internal mixer are shown in figure 1 , at 180°C and the strain is 5% under the condition of viscosity change curve with frequency see figure 2 .

Embodiment 3

[0029] Synthesis of Long-chain Branched Polylactic Acid by Functional Group Reaction and Linear Enantiomer Polylactic Acid

[0030] Add 100 parts by weight of linear polylactic acid resin and 5.3 parts of linear enantiomer polylactic acid to an internal mixer with a rotation speed of 20 rpm at 250 ° C, and then add 0.16 parts of 1,3,5-trimethyl -2,4,6-tris(3,5-di-tert-butyl-4-hydroxybenzyl)benzene, 0.55 parts of N,N,N',N'-tetraglycidyl-4,4'di Aminodiphenylmethane, mixed for 2 minutes; then the internal mixer was raised to 100rpm, and blended until the reaction was completed, and stopped after about 3.5 minutes to obtain long-chain branched polylactic acid. The melt index test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com