High thermal conductivity wave-absorbing organosilicon composition and preparation method thereof

A technology of organosilicon and composition, applied in the field of high thermal conductivity wave absorbing organosilicon composition and preparation thereof, can solve the problems that the thermal conductivity of the product is difficult to meet the requirements for use, the thickness of the material is difficult to control, and the continuous production is difficult, and it is beneficial to large-scale production. Large-scale continuous production, simple operation, and the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

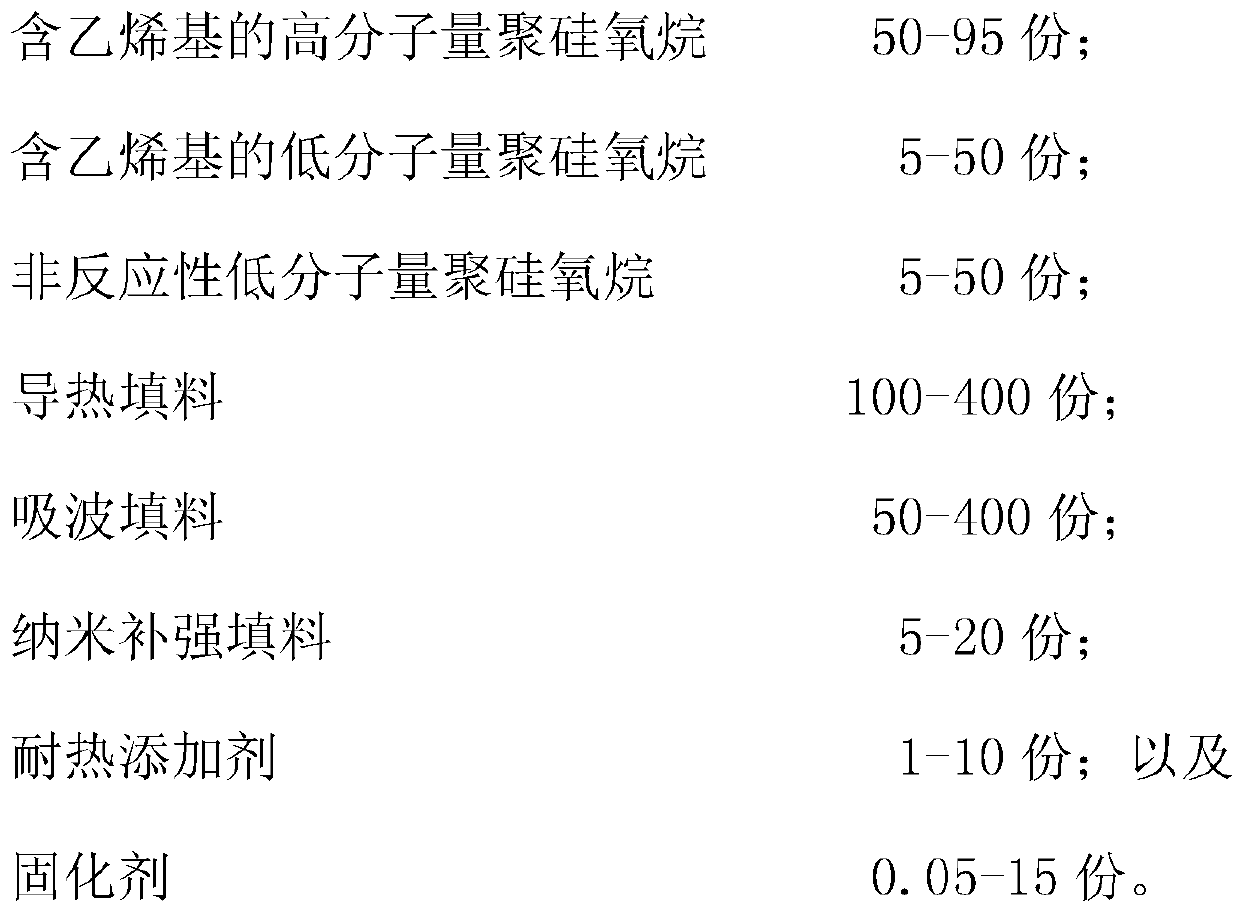

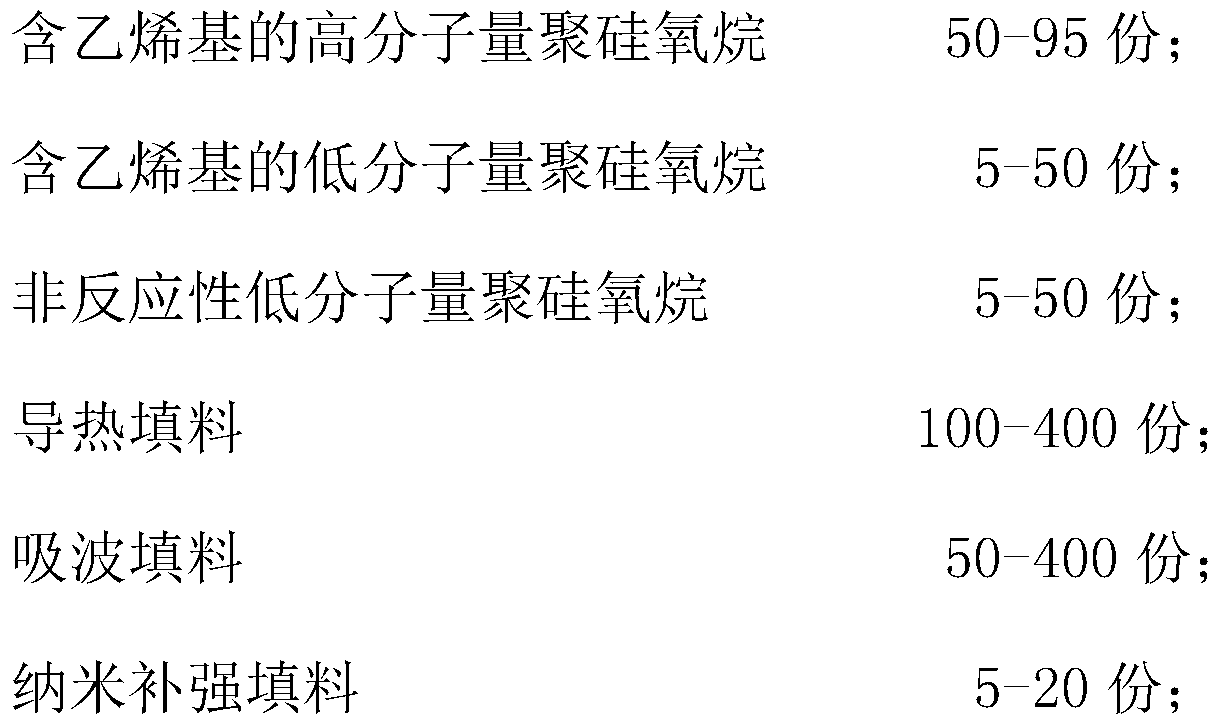

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the high thermal conductivity and wave-absorbing silicone composition of the present invention may include the following steps:

[0041] S1. Mix the raw materials in parts by mass to form a mixture.

[0042] S2. Extrude the mixture into a sheet through an extruder.

[0043] Among them, the length of the extrusion cavity of the extruder is 0.5cm-50cm, preferably 2cm-10cm; the length of the extrusion cavity is less than 2cm, the orientation is insufficient, and it is difficult to extrude if the length is greater than 10cm. The width of the extrusion cavity is 0.1mm-50mm. It is preferably 1cm-5cm; the width of the extrusion cavity is less than 1cm, which will result in too small size of the finished product, and it is difficult to extrude a complete sheet if it is greater than 5cm. The thickness of the extrusion cavity is 0.1mm-10mm, preferably 0.3mm-2mm; if the thickness of the extrusion cavity is less than 0.3mm, it will be difficult for the sheet to...

Embodiment 1

[0052] Separately 700g of long-chain polyvinyl-terminated dimethylsiloxane with an average molecular weight of 500,000, 100g of vinyl-terminated dimethylsiloxane with an average molecular weight of 2000, and 200g of polydimethylsiloxane with an average molecular weight of 1000 Silicone was added to a 2L kneader, kneaded and stirred at room temperature for 5 minutes, and then added in batches 1000g of flake graphite powder with an average particle size of 25μm, 500g of carbon-based nickel powder with an average particle size of 3μm, and 500g average particle size. Carbon-based iron powder with a diameter of 2μm, 200g BET specific surface area of 200m 2 / g of fumed silica, mixed for 2 hours at room temperature. After mixing, take out 400g and add 2g long-chain polydimethylsiloxane mixture containing 50% 2,5-dimethyl-2,5-di-tert-butylperoxyhexane and an average molecular weight of 500,000. Mix uniformly on an open mill, and extrude through a screw extruder into a sheet with a th...

Embodiment 2

[0054] Respectively, 600g of long-chain polydimethylsiloxane with an average molecular weight of 500,000, 200g of vinyl-terminated dimethylsiloxane with an average molecular weight of 2000, and 200g of polydimethylsiloxane with an average molecular weight of 500 Add to a 2L kneader, knead and stir at room temperature for 5 minutes, and then add 1000g of flake graphite powder with an average particle size of 40μm, 500g of carbon-based nickel powder with an average particle size of 3μm, and 500g with an average particle size of 2μm. Carbon-based iron powder, 200g BET specific surface area of 200m 2 / g of fumed silica, mixed for 2 hours at room temperature. After mixing, take out 400g and add 2g long-chain polydimethylsiloxane mixture containing 50% 2,5-dimethyl-2,5-di-tert-butylperoxyhexane and an average molecular weight of 500,000. Mix uniformly on an open mill, and extrude into a 0.6mm thick, 30mm wide and 40cm long sheet through a screw extruder. This kind of sheet is then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com