A kind of preparation method of graphene-reinforced copper-based electrical contact material

An electrical contact material, graphene technology, applied in circuits, electrical switches, electrical components and other directions, can solve the problems of reducing the electrical conductivity and thermal conductivity of copper contact materials, and it is difficult to obtain comprehensive performance copper-based contact materials, etc. Conducive to large-scale continuous production, high hardness and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

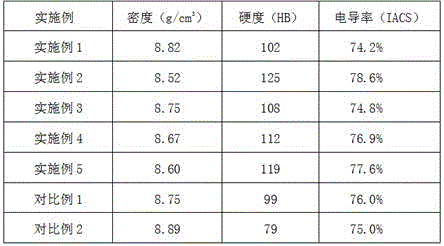

Examples

Embodiment 1

[0027] (1) Put the copper powder with a weight content of 1.0% graphene and 99.0% into a ball mill to mix the powder. The process parameters of the ball mill are: the ball mill tank is first evacuated and then filled with argon protection, the speed is 150r / min, and the ball mill is 20 minutes. Stop for 5 minutes, turn clockwise and counterclockwise alternately, and the total mixing time is 4 hours. After powder mixing, cold press molding is made into a copper-graphene master alloy, the pressure is 200MPa, the holding time is 5 minutes, the graphene is 1-10 layers, the purity of the copper powder is 99.9%, and the particle size is 150 mesh.

[0028] (2) Copper with a purity of 99.9% is smelted in an intermediate frequency furnace and covered with glass or borax to prevent oxidation of the copper melt. The quality of glass or borax is 0.8-1.2% of the weight of the charge.

[0029] (3) Add 0.03% copper weight rare earth yttrium into the copper melt, wrap the rare earth with copp...

Embodiment 2

[0032] (1) Put the copper powder with a weight content of 5.0% graphene and 95.0% into a ball mill to mix the powder. The process parameters of the ball mill are: the ball mill tank is first evacuated and then filled with argon protection, the speed is 350r / min, and the ball mill is 15 minutes. Stop for 5 minutes, turn clockwise and counterclockwise alternately, and the total mixing time is 2 hours. After powder mixing, cold press molding is made into a copper-graphene master alloy, the pressure is 400MPa, the holding time is 3 minutes, the graphene is 1-10 layers, the purity of the copper powder is 99.9%, and the particle size is 300 mesh.

[0033] (2) Copper with a purity of 99.9% is smelted in an intermediate frequency furnace and covered with glass or borax to prevent oxidation of the copper melt. The quality of glass or borax is 0.8-1.2% of the weight of the charge.

[0034] (3) Add lanthanum-rich mixed rare earth metals with 2% copper weight in the copper melt, wrap the ...

Embodiment 3

[0037] (1) Put copper powder with a weight content of 2.0% graphene and 98.0% into a ball mill to mix the powder. The process parameters of the ball mill are: the ball mill tank is first evacuated and then filled with argon protection, the speed is 200r / min, and the ball mill is 15 minutes. Stop for 5 minutes, turn clockwise and counterclockwise alternately, and the total mixing time is 3 hours. After powder mixing, cold press molding is made into a copper-graphene master alloy, the pressure is 300MPa, the holding time is 4 minutes, the graphene is 1-10 layers, the purity of the copper powder is 99.9%, and the particle size is 200 mesh.

[0038] (2) Copper with a purity of 99.9% is smelted in an intermediate frequency furnace and covered with glass or borax to prevent oxidation of the copper melt. The quality of glass or borax is 0.8-1.2% of the weight of the charge.

[0039] (3) Add lanthanum-rich mixed rare earth metal with 1.0% copper weight in the copper melt, wrap the rar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com