Modified resin, raw material composition, preparation method, foaming material and application

A technology of raw material composition and modified resin, which is applied in modified resin, raw material composition, preparation, foaming material and application fields, and can solve the problems of unsatisfactory melt rheological properties and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

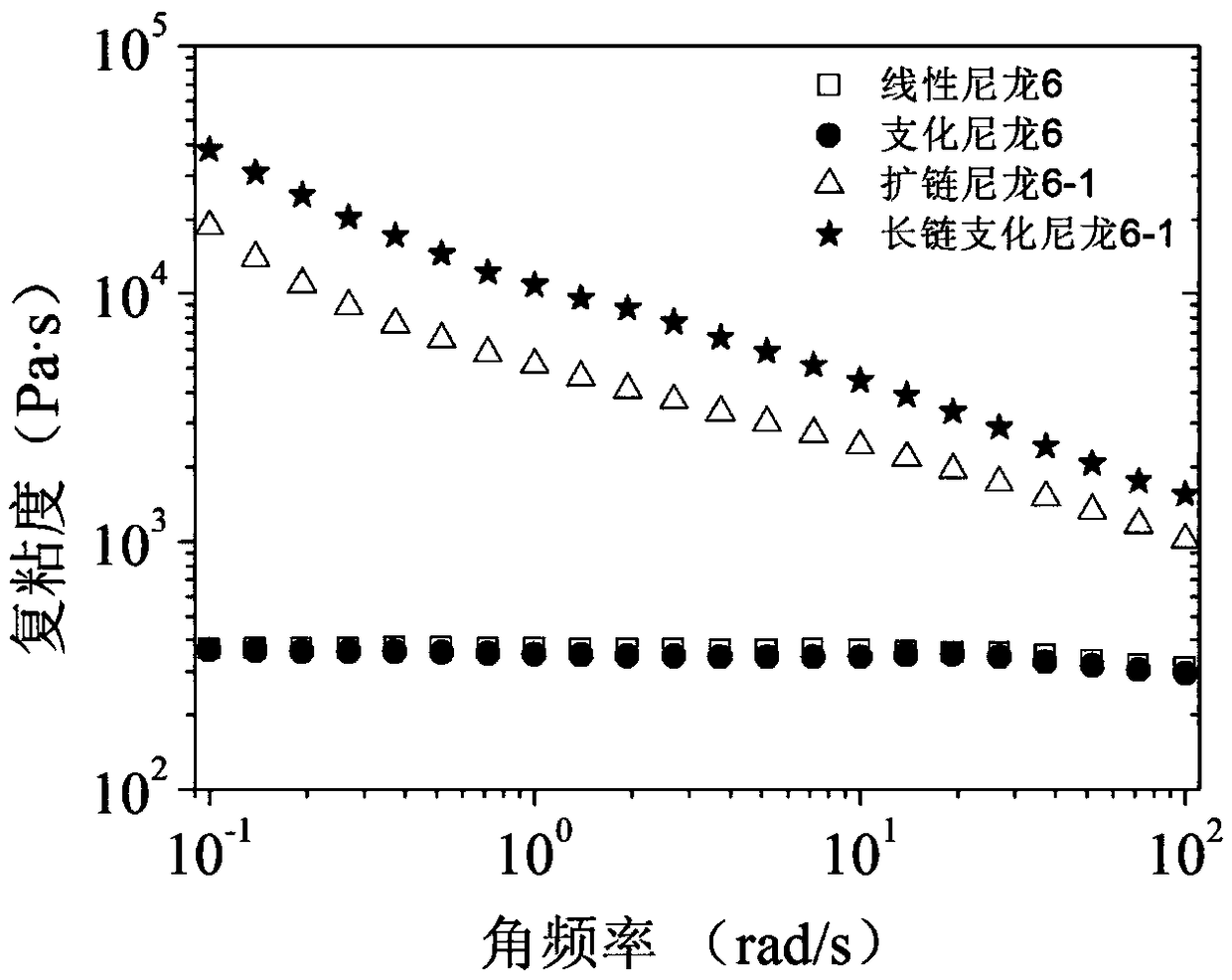

Embodiment 1

[0080] With the nylon 6 resin of 100 weight parts, the epoxy chain extender of 2.0 weight parts Acrylate polymer and 0.50 parts by weight of antioxidant 1010 are mixed evenly and added to a twin-screw extruder with a rotation speed of 200rpm, melted and blended at 240°C, and the chain-extended nylon 6-1 is obtained by reactive extrusion . The weight-average molecular weight of the chain-extended nylon 6-1 is 32000 g / mol, the molecular weight distribution index is 1.8, and the viscosity is 21000 Pa·s.

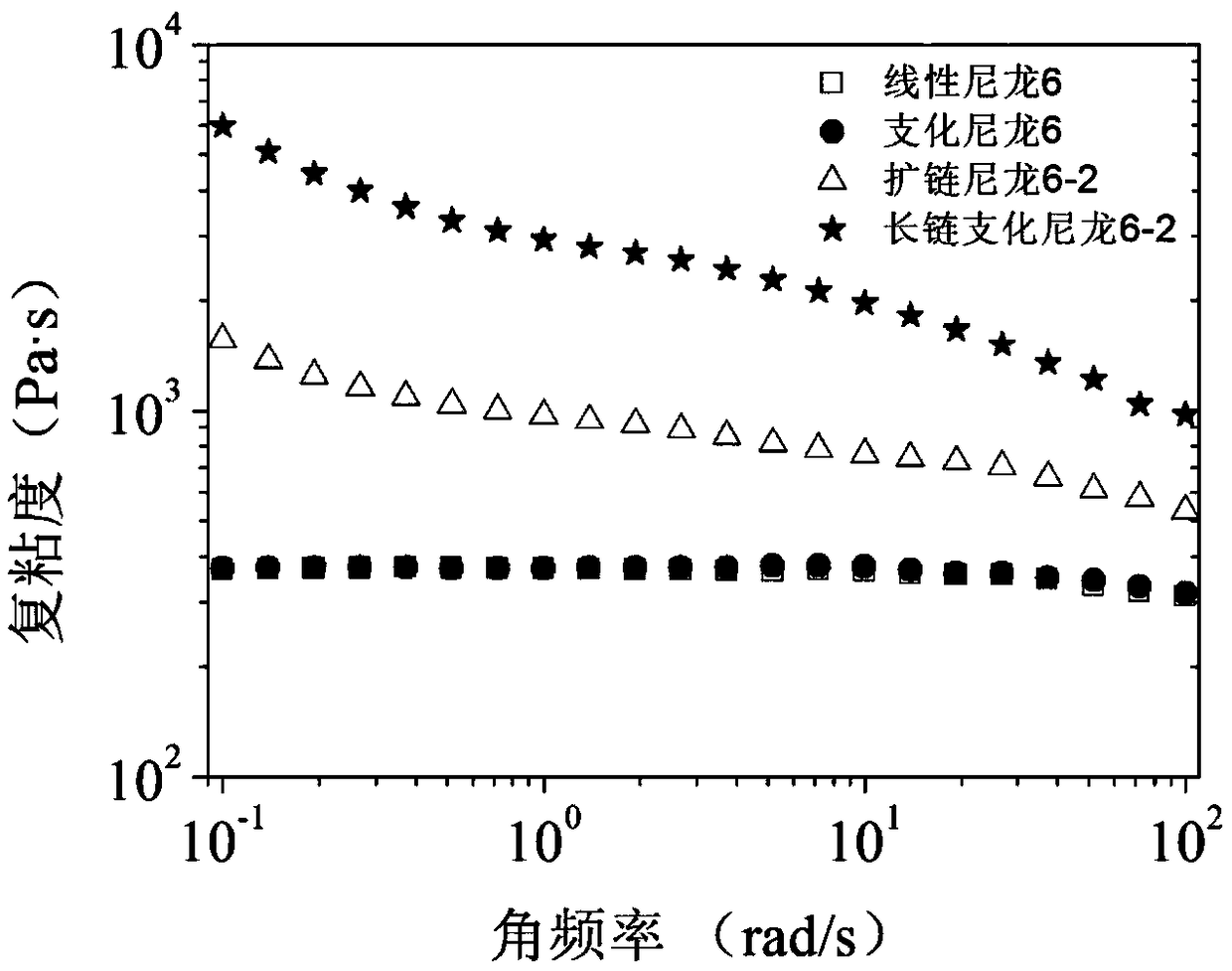

Embodiment 2

[0082] The nylon 6 resin of 100 parts by weight, the epoxy chain extender KLE-4370 acrylate polymer of 2.0 parts by weight and the antioxidant 1010 of 0.5 parts by weight, join the twin-screw extruder that rotating speed is 200rpm after mixing uniformly In 240°C, melt blending was carried out, and chain-extended nylon 6-2 was prepared by reactive extrusion. The weight average molecular weight of chain-extended nylon 6-2 is 31000g / mol, the molecular weight distribution index is 1.7, and the viscosity is 20500Pa·s.

Embodiment 3

[0084] With the nylon 6 resin of 100 weight parts, the epoxy chain extender of 2.0 weight parts Acrylate polymer, 3.0 parts by weight of maleic anhydride grafted polypropylene and 0.50 parts by weight of antioxidant 1010 were mixed uniformly and then added to a twin-screw extruder with a rotation speed of 200 rpm, melted and blended at 240 ° C, Long chain branched nylon 6-1 was prepared by reactive extrusion. The weight-average molecular weight of long-chain branched nylon 6-1 is 48000g / mol, the molecular weight distribution index is 2.3, and the viscosity is 75000Pa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com