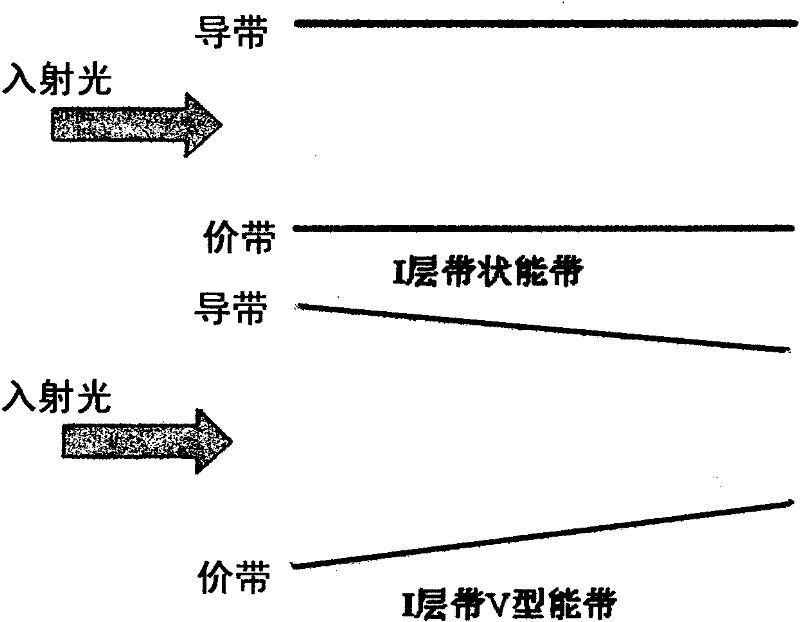

Amorphous silicon solar cell optimized by modulating energy band structure of intrinsic layer via hydrogen and manufacturing method thereof

An energy band structure, solar cell technology, applied in chemical instruments and methods, circuits, crystal growth, etc., can solve problems such as increased risk and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The equipment used for the growth of the present invention is a plasma-assisted chemical vapor deposition system (PECVD), including reaction chambers (mounting chamber, doping chamber and intrinsic chamber), vacuum system, substrate heating and temperature control system, gas path control system etc. The gas used in the deposition cell is 99.99% high-purity silane and hydrogen produced by a hydrogen generator as a reaction gas, with a purity of 0.5% (dilute gas is hydrogen) of borane and 1% phosphine (dilute gas is hydrogen) as a dopant gas. The frequency of the radio frequency power source for exciting the plasma is 13.56 MHz.

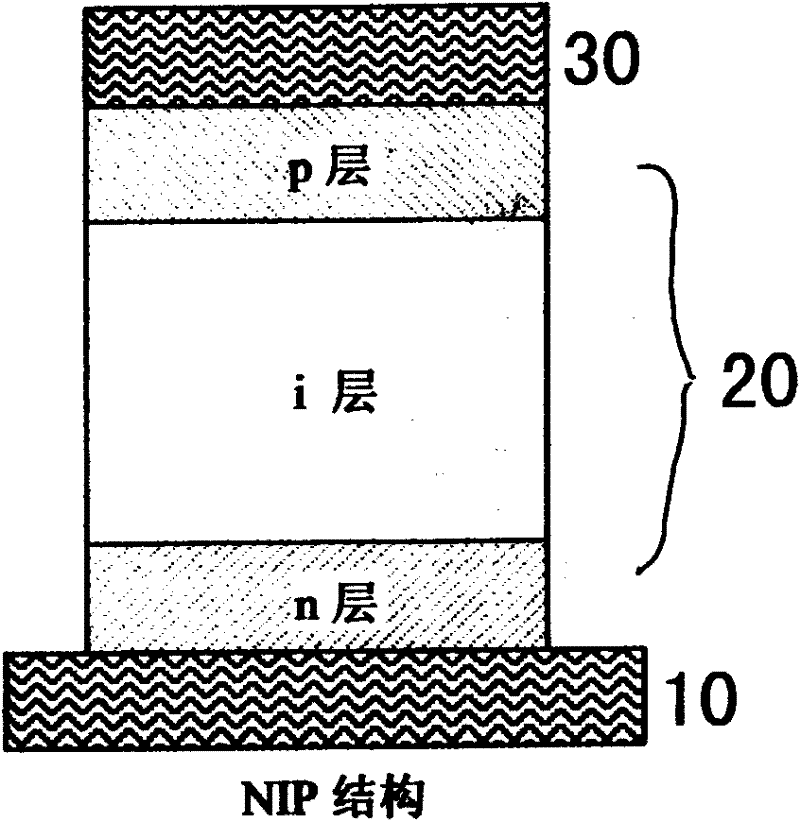

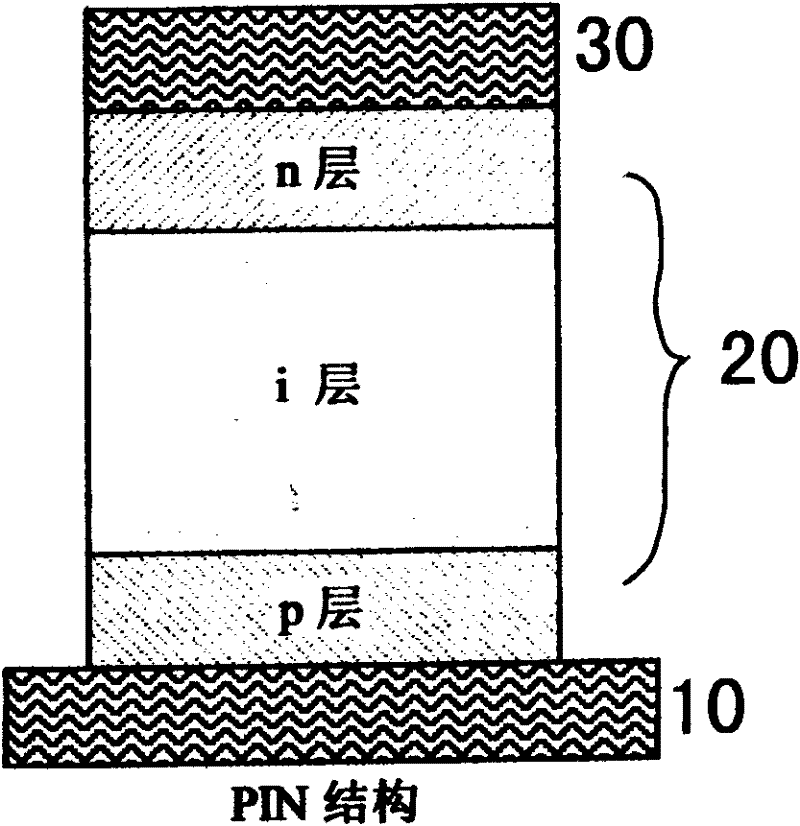

[0027] Please refer to Fig. 1 (a), shown in Fig. 1 (b), the present invention provides a kind of hydrogen modulation intrinsic layer energy band structure optimization amorphous silicon solar cell manufacturing method, comprises the following steps:

[0028] Step 1: clean a substrate 10, put it into a plasma-enhanced chemical vapor deposition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com