Flexible solar battery and manufacturing method thereof

A technology of solar cells and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of slow growth of flexible solar cells, complicated production process, high cost, etc., shorten the waiting time for cooling down, install And the effect of easy disassembly and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

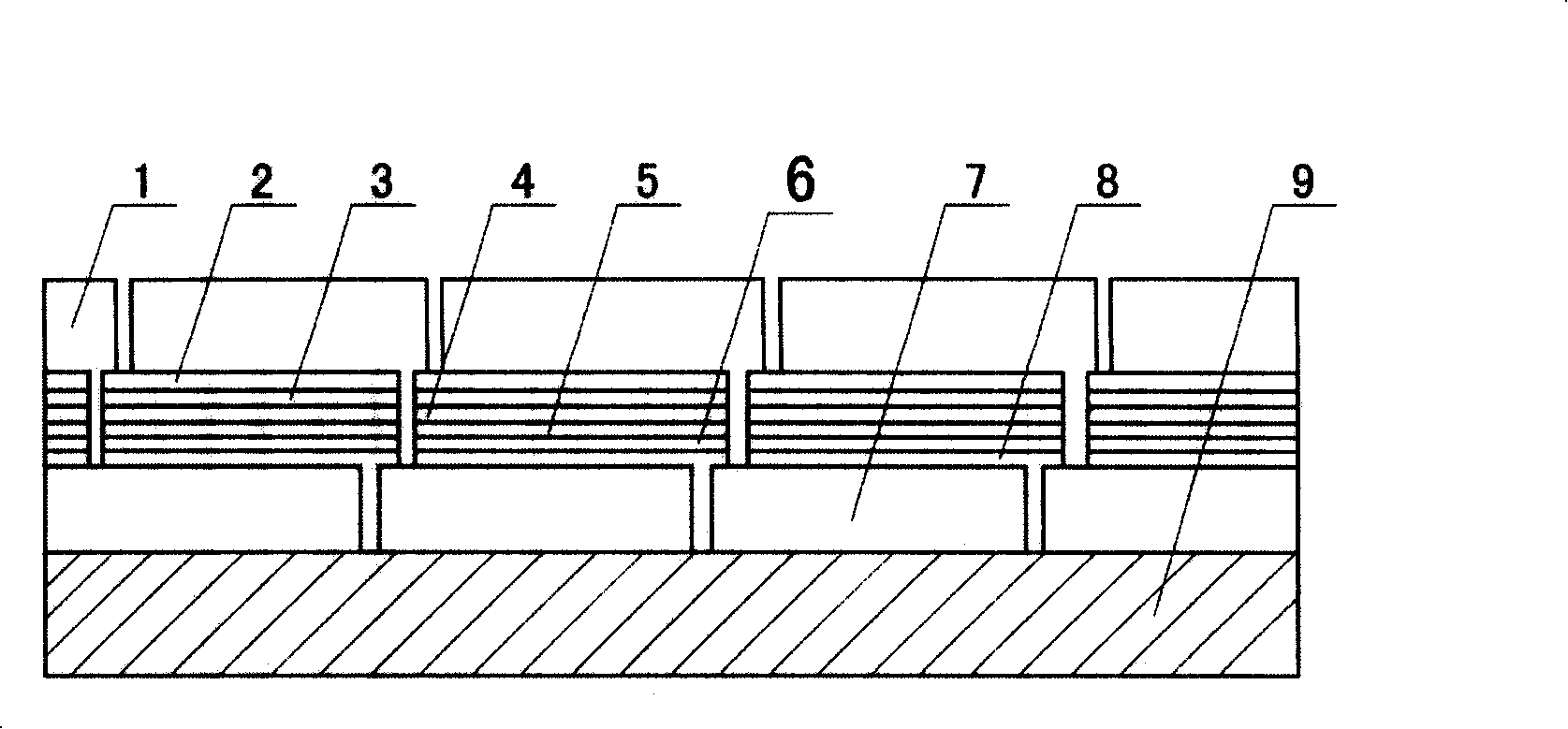

[0052] Example 1 Process for preparing flexible amorphous silicon solar cells:

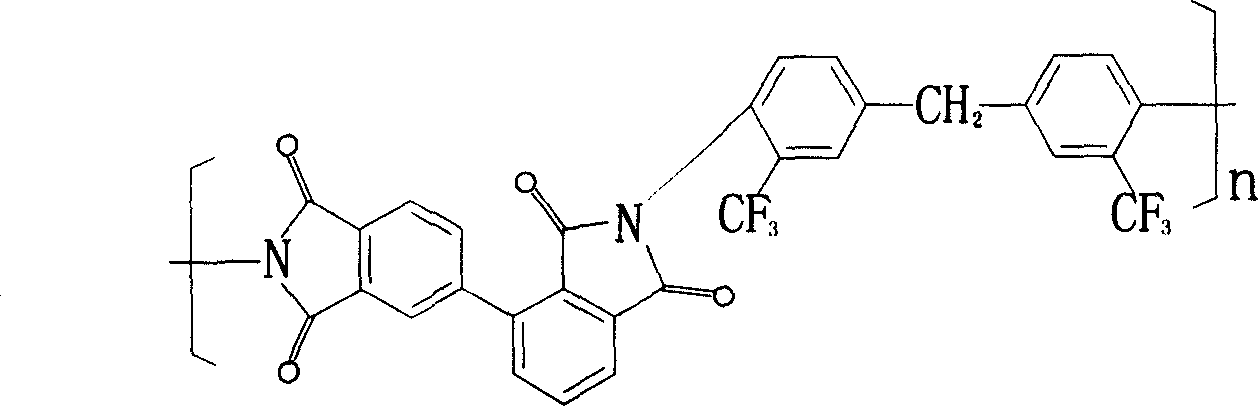

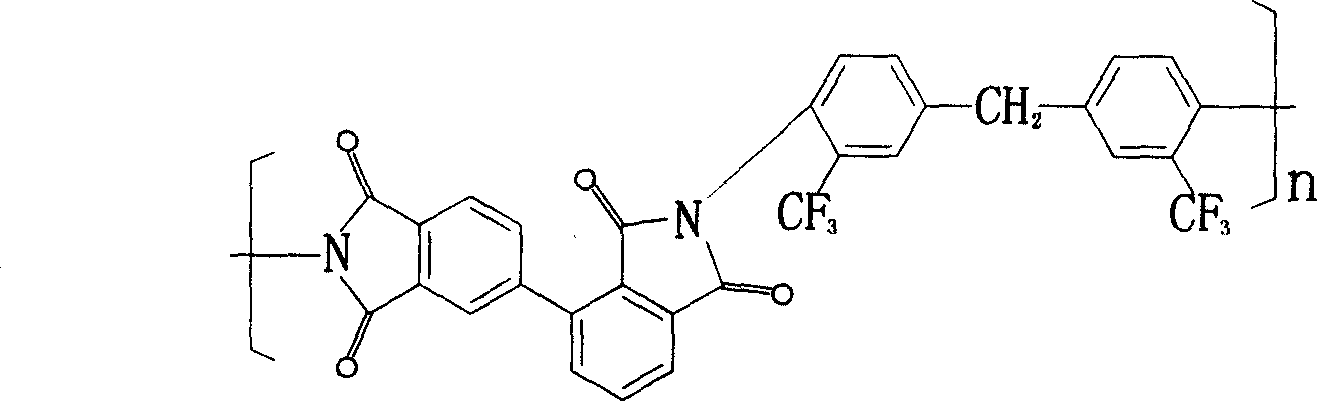

[0053] (1), according to 3,3'-trifluorodimethyl-4,4'diaminodiphenylmethane: N,N-dimethylacetamide: 2,3,3',4'-biphenyl tetra Formic acid dianhydride = 0.9: 45: The polyamic acid slurry prepared by the molar ratio of 0.9 is vacuum filtered, and then a layer of film is made on a 0.5mm thick stainless steel plate by screen printing or spraying, and put into Dry in an oven according to the following procedures: 120°C / 1h; 170°C / 1h; 280°C / 1h; 350°C / 1h. After cooling, a uniform transparent modified polyimide substrate is obtained.

[0054] (2), the modified polyimide substrate is installed on the substrate frame and stretched out. The substrate frame is 1220mm long and 356mm wide.

[0055] (3) Depositing a layer of ZnO transparent conductive film with sheet resistance 15Ω / □ and light transmittance 93% on the modified polyimide substrate by magnetron sputtering at a temperature of 350°C.

[0056] (4) La...

example 2

[0066] The manufacturing steps of the flexible amorphous silicon solar cell are the same as in Example 1, only the modified PI substrate production formula in step 1, the deposition temperature of the amorphous silicon film in step 7, and the thickness of each layer of film are changed:

[0067] Press 3,3'-trifluorodimethyl-4,4'diaminodiphenylmethane: N,N-dimethylacetamide: 2,3,3',4'-biphenyltetracarboxylic dianhydride= The diamine monomer 3,3'-trifluorodimethyl-4,4'diaminodiphenylmethane was added to the N,N-dimethylacetamide DMAc solution at a molar ratio of 1.0:47:1.0, fully Inject nitrogen, stir at room temperature for 5 minutes, start to add 2,3,3`,4`-biphenyltetracarboxylic dianhydride a-BPDA. Under nitrogen protection, stir at room temperature for 20 hours. After vacuum defoaming and filtration, Obtain a colorless and transparent polyamic acid viscous solution. Spread the solution on a clean glass plate, then put it in an oven and dry it according to the following proce...

example 3

[0070] The manufacturing steps of the flexible amorphous silicon solar cell are the same as in Example 1, only the deposition temperature of the ZnO transparent conductive film in step 3 and the deposition temperature of the microcrystalline silicon thin film in step 7 are changed:

[0071] A ZnO transparent conductive film with a sheet resistance of 14Ω / □ and a light transmittance of 90% was deposited on the modified PI substrate by magnetron sputtering at a temperature of 370°C.

[0072] Deposit the P-type microcrystalline silicon thin film layer of the bottom cell at a temperature of 400°C and the N-type microcrystalline silicon thin film layer of the top cell Form a tunnel junction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com