Amorphous silicon-crystal silicon heterojunction solar battery

A solar cell and crystalline silicon technology, applied in the field of solar cells, can solve the problems of large voltage, increase the lateral conduction resistance of the N-type thin layer, affect the photoelectric conversion efficiency of the battery, etc., so as to reduce the series resistance, improve the photoelectric conversion efficiency, reduce the The effect of coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

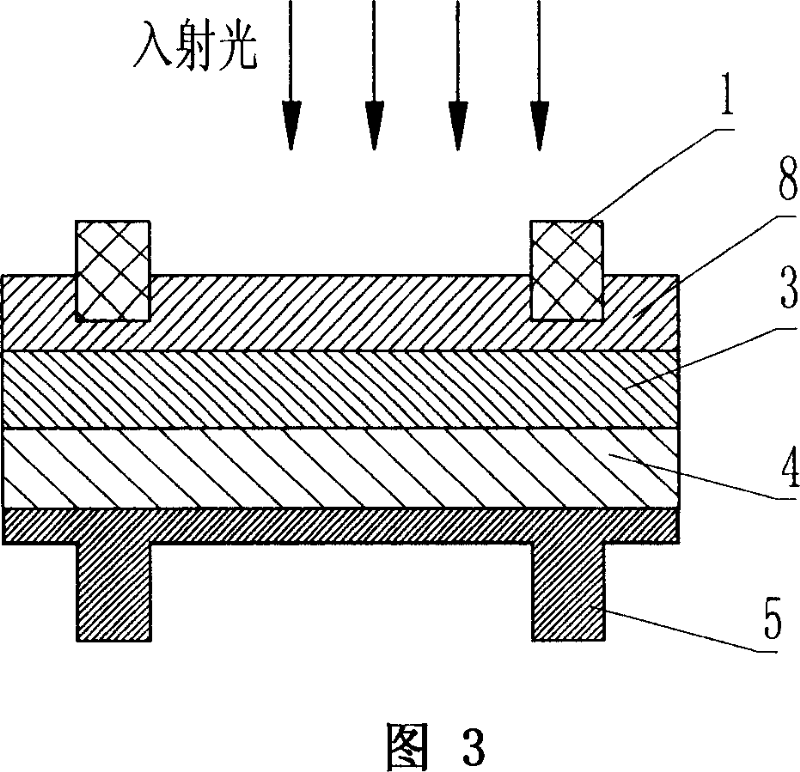

[0017] Fig. 3 is an embodiment of the present invention taking the P-type substrate material as an example, a schematic structural view of an amorphous silicon-crystalline silicon heterojunction solar cell, including: a light-receiving surface electrode 1, an N-type silicon diffusion layer 3, a P-type silicon Substrate layer 4 and back electrode 5. The present invention also prepares a layer of amorphous silicon film layer 8 between the light receiving surface electrode 1 and the N-type silicon diffusion layer 3 on the light-receiving surface side of the solar cell, and the amorphous silicon film layer 8 and the N-type silicon diffusion layer 3 form a different High-quality high-low junction structure, that is, amorphous silicon has the same conductivity type as the crystalline silicon it contacts. Therefore, the lamination sequence between different materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com