Patents

Literature

52results about How to "Avoid bombardment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shelf to consumer platform

InactiveUS20140249928A1Avoid bombardmentPrevent the bombardment of consumersMarketingActive stateMultimedia

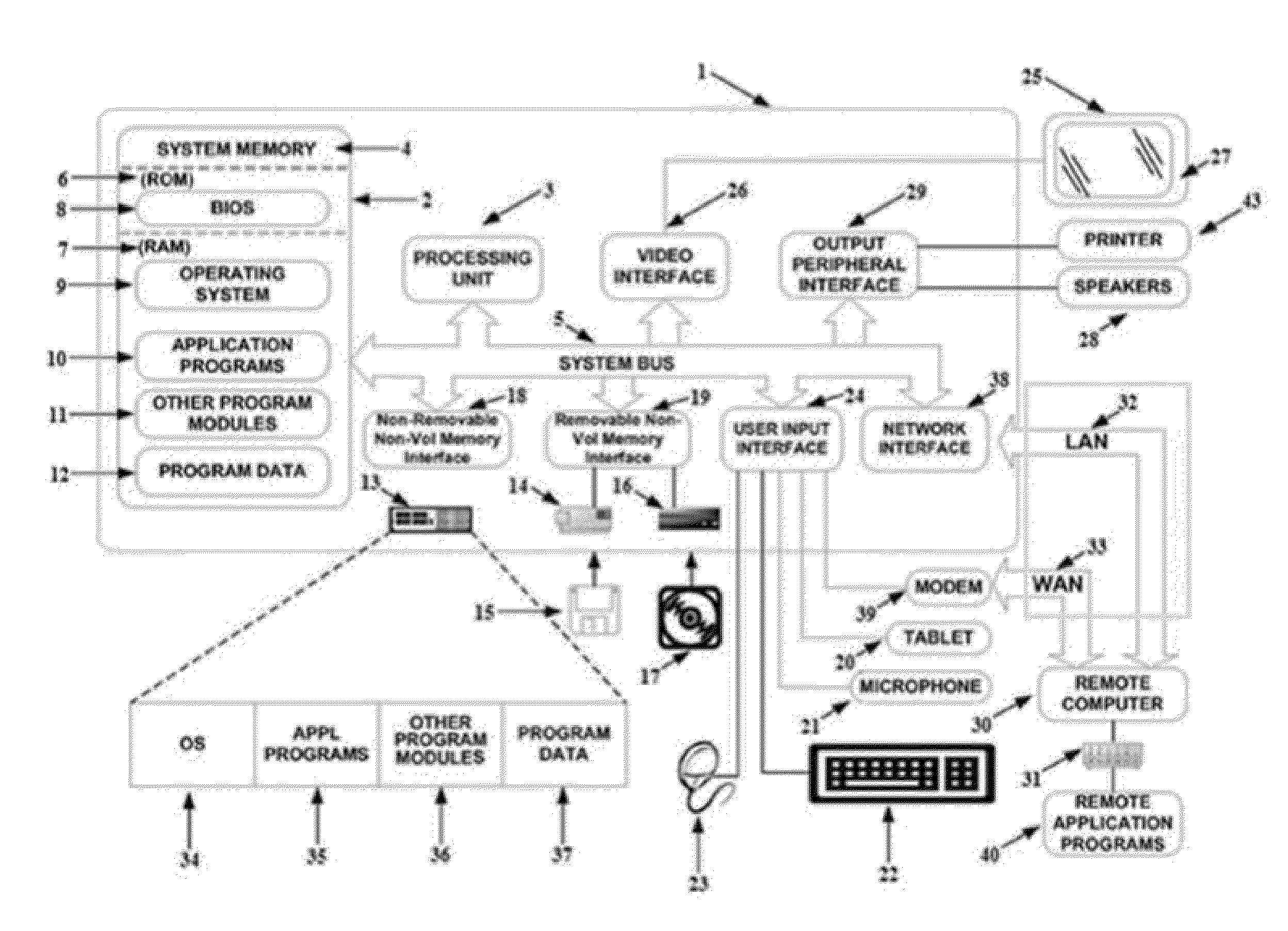

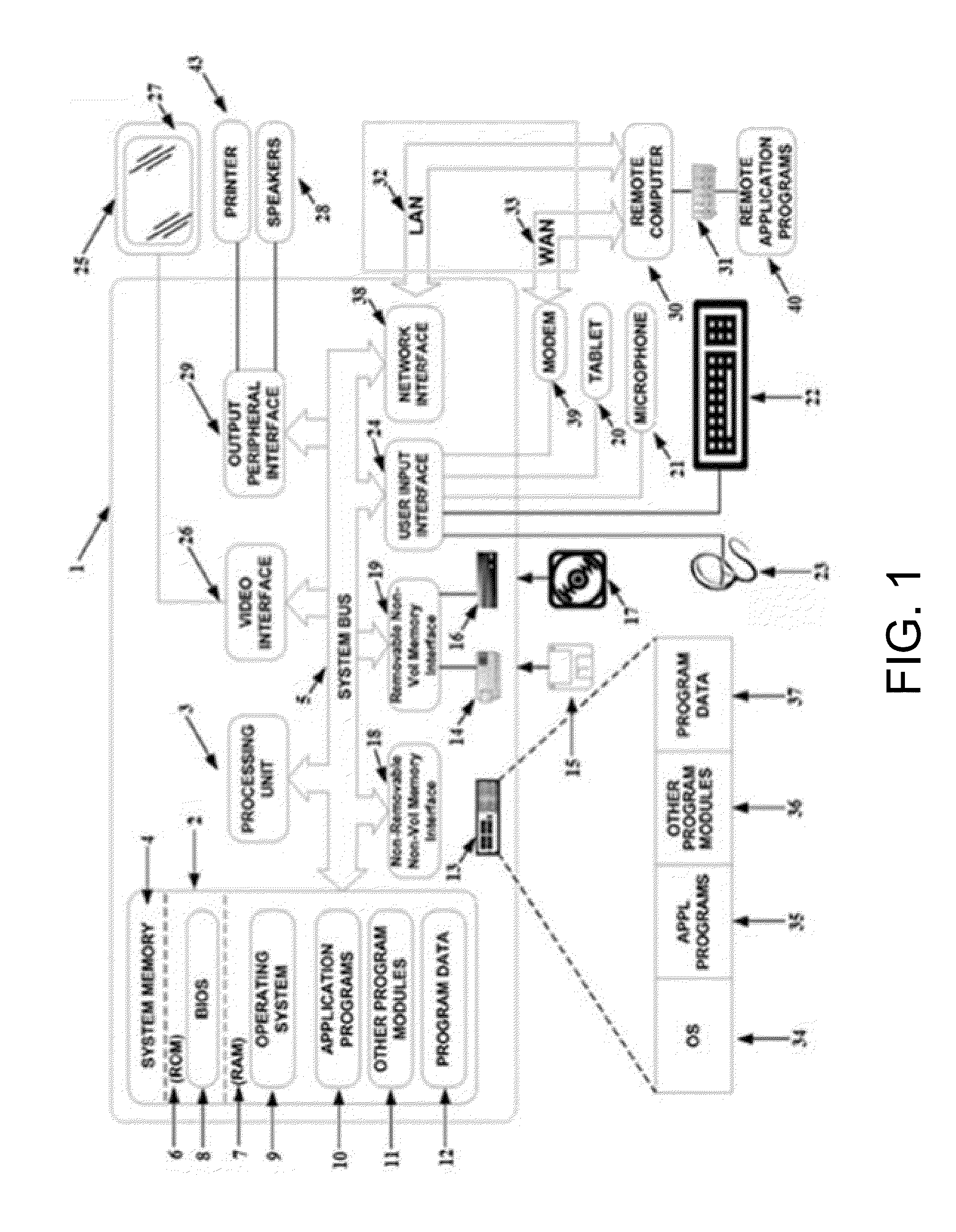

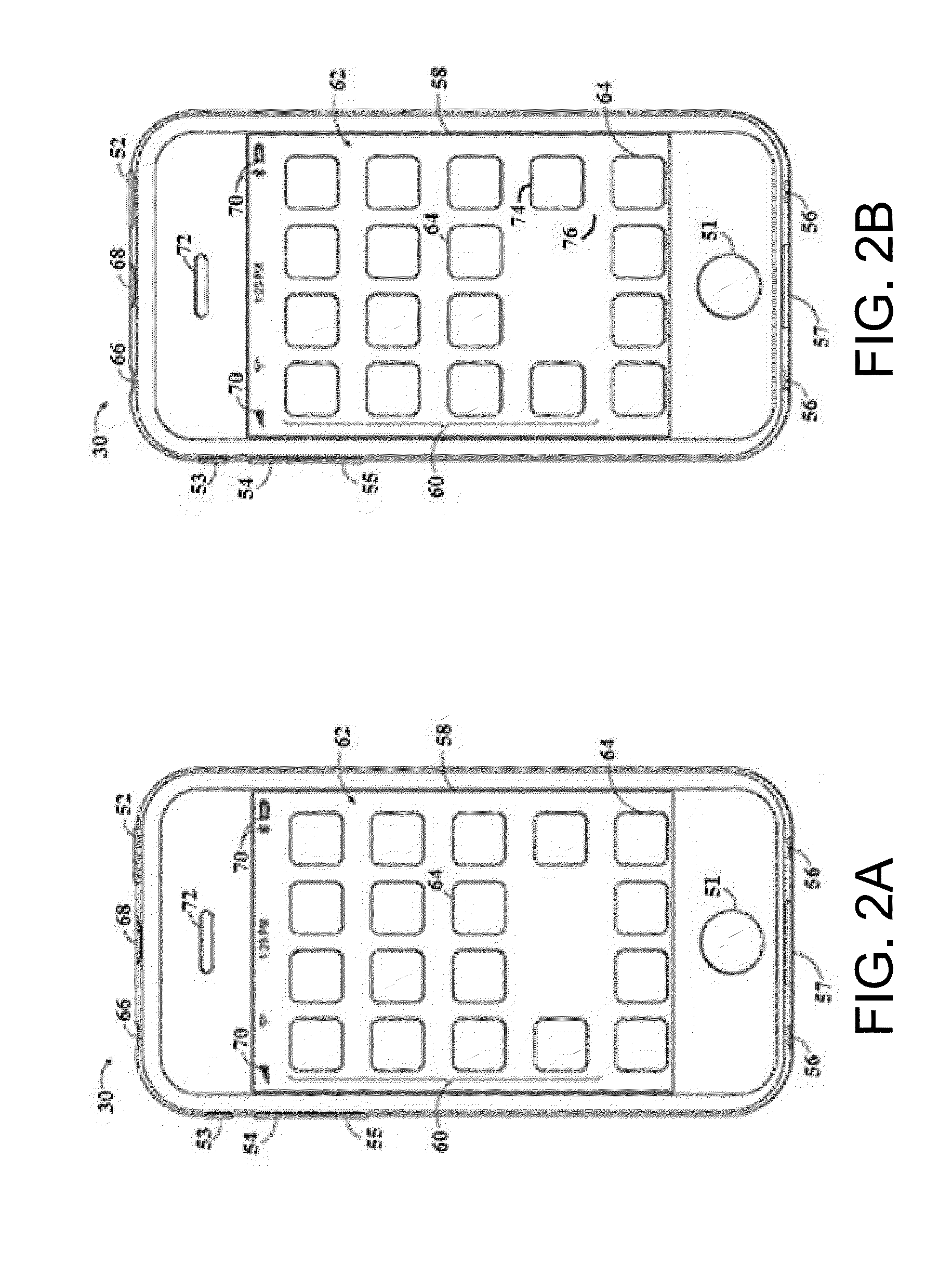

The present disclosure provides a system, apparatus and means for addressing the limitations of existing technology and practices with respect to in-store advertising. The present disclosure enables marketers to direct commercial messages to consumers whilst enabling consumers to control or influence if and when messages are received, as well as the content of the messages. The disclosure can provide this functionality is through the use of broadcast beacons and demand beacons. The disclosure also provides a means for interacting with applications located on PEDs, including from a sleeping or non-active state and ensuring that the messages transmitted are secure. The disclosure also provides a means for marketers to design, track and alter in real-time a marketing strategy, including on a store-by-store basis.

Owner:ABL IP HLDG

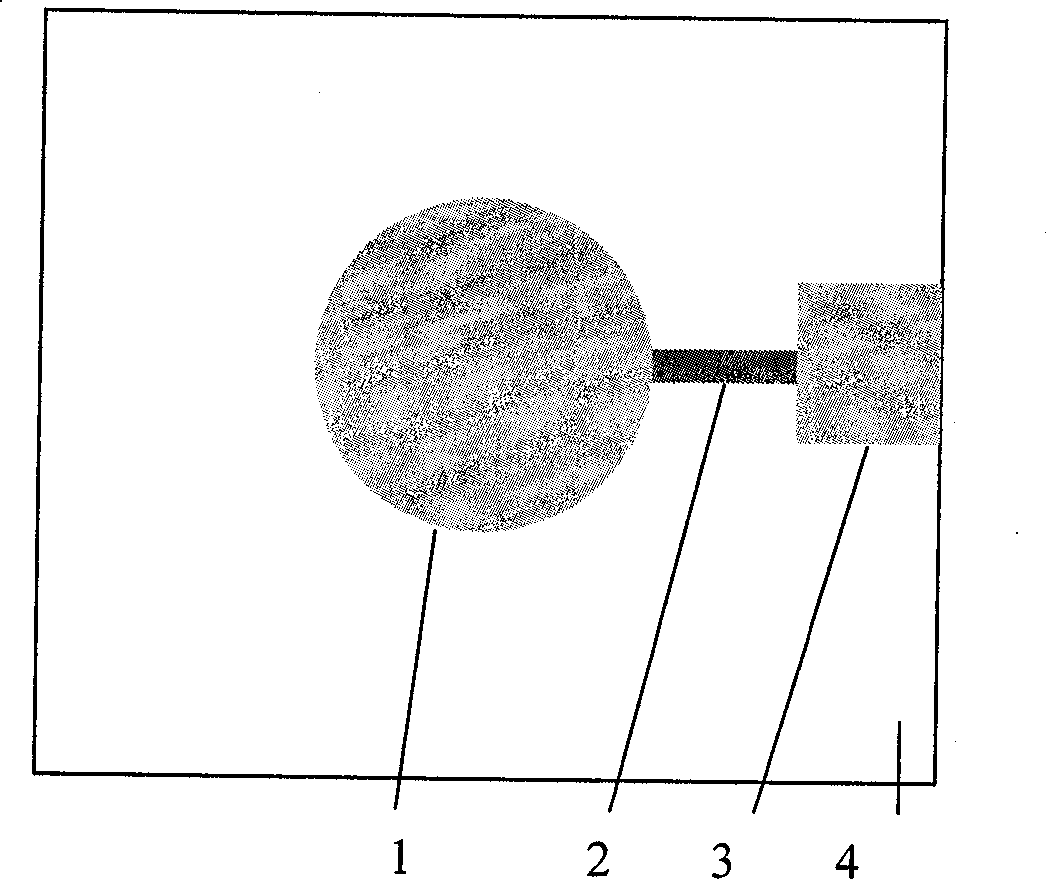

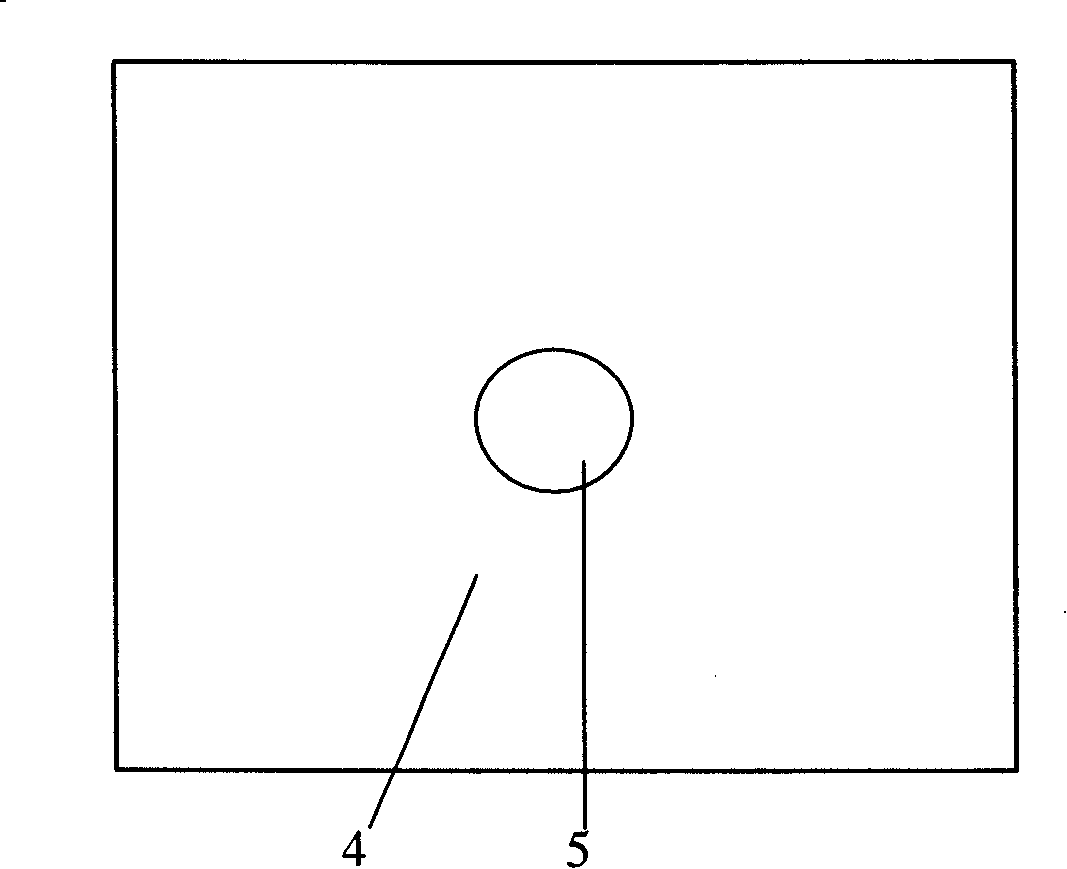

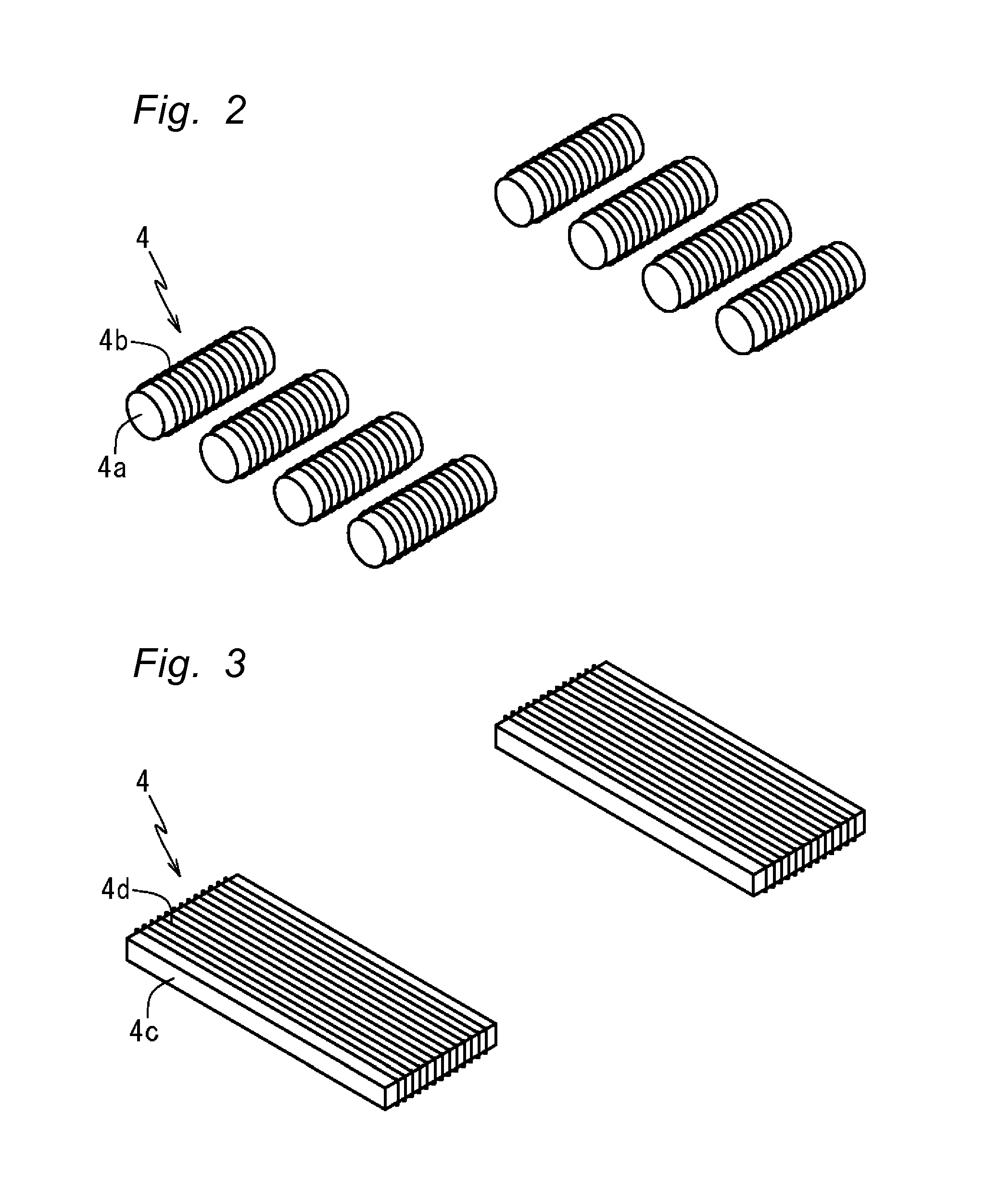

Emitting laser for etching top end non-doping intrinsic layer asymmetric metal membrane vertical cavity surface

InactiveCN101202420AAvoid recombinationReduce compoundingLaser detailsLaser active region structureVertical-cavity surface-emitting laserLaser array

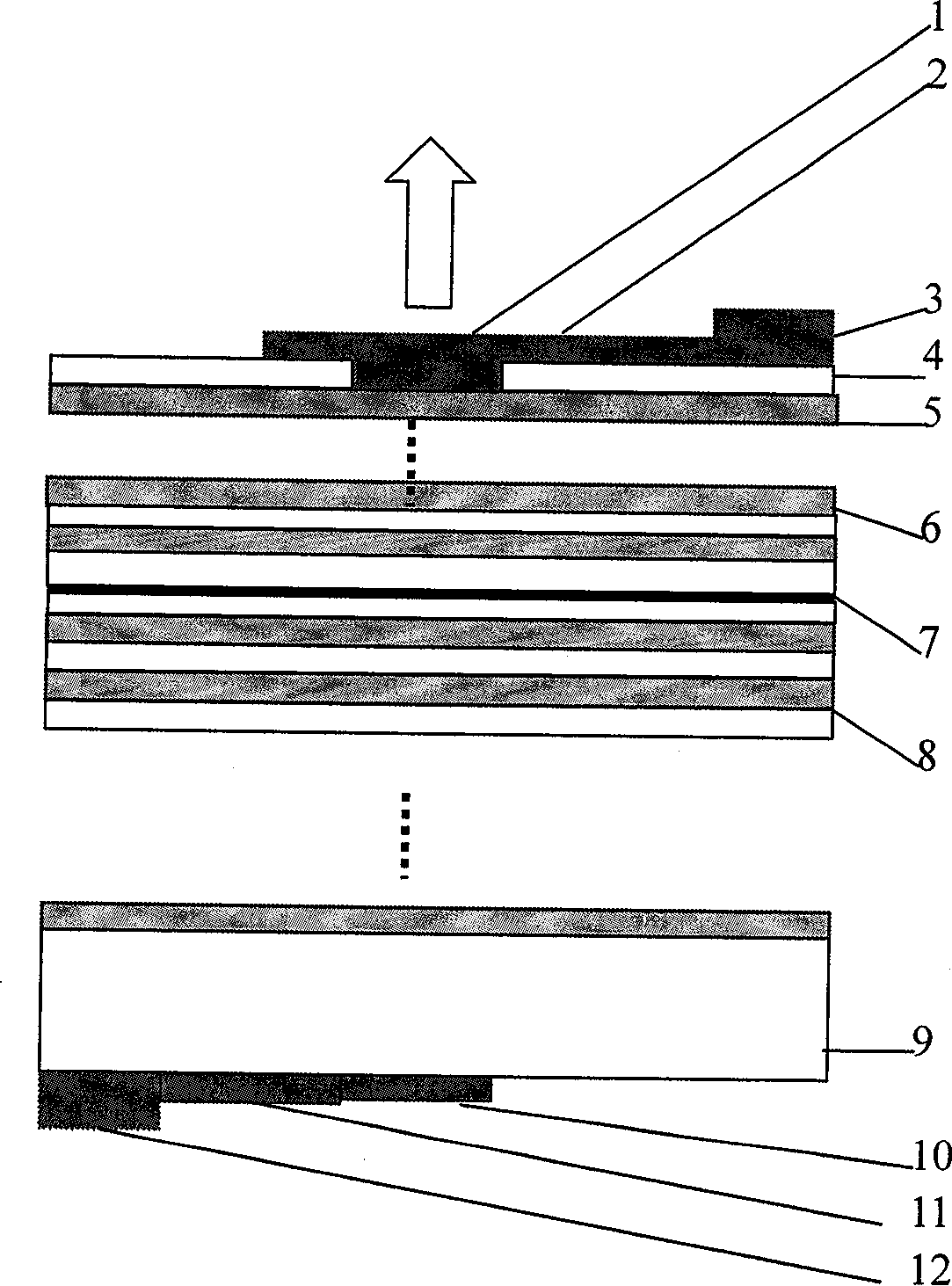

The invention relates to an etching apex non-doped intrinsic layer asymmetrical metal film vertical cavity surface emitting laser and a preparation method thereof. The invention comprises a Bragg reflector, a high resistive layer, an electrode, a substrate and a quantum well active region. The upper surface is etched with a round metal reflection film, a metal film lead, a contact layer of the metal film and an upper electrode and the upper electrode; the lower surface of the substrate is provided with the round metal reflection film, a lower surface metal film lead and a lower surface electrode. By introducing the non-doped intrinsic layer to etch the current aperture and combining the upper surface with the substrate surface to etch a metal film asymmetrical structure in order to implement the restriction to current and optical field, the invention has the efficacies of the electrode and the reflector of the metal film, simplifies a vertical cavity emitting laser array integration process, reduces the logarithm of distributed Bragg reflector, restricts the diffusion area of the current, improves the photoelectric coupling efficiency of injected current, avoids proton bombardment or respective oxidation process and is beneficial for integration as the intrinsic high-resistive layer and a chip implement the grown in one operation.

Owner:HEBEI UNIV OF TECH

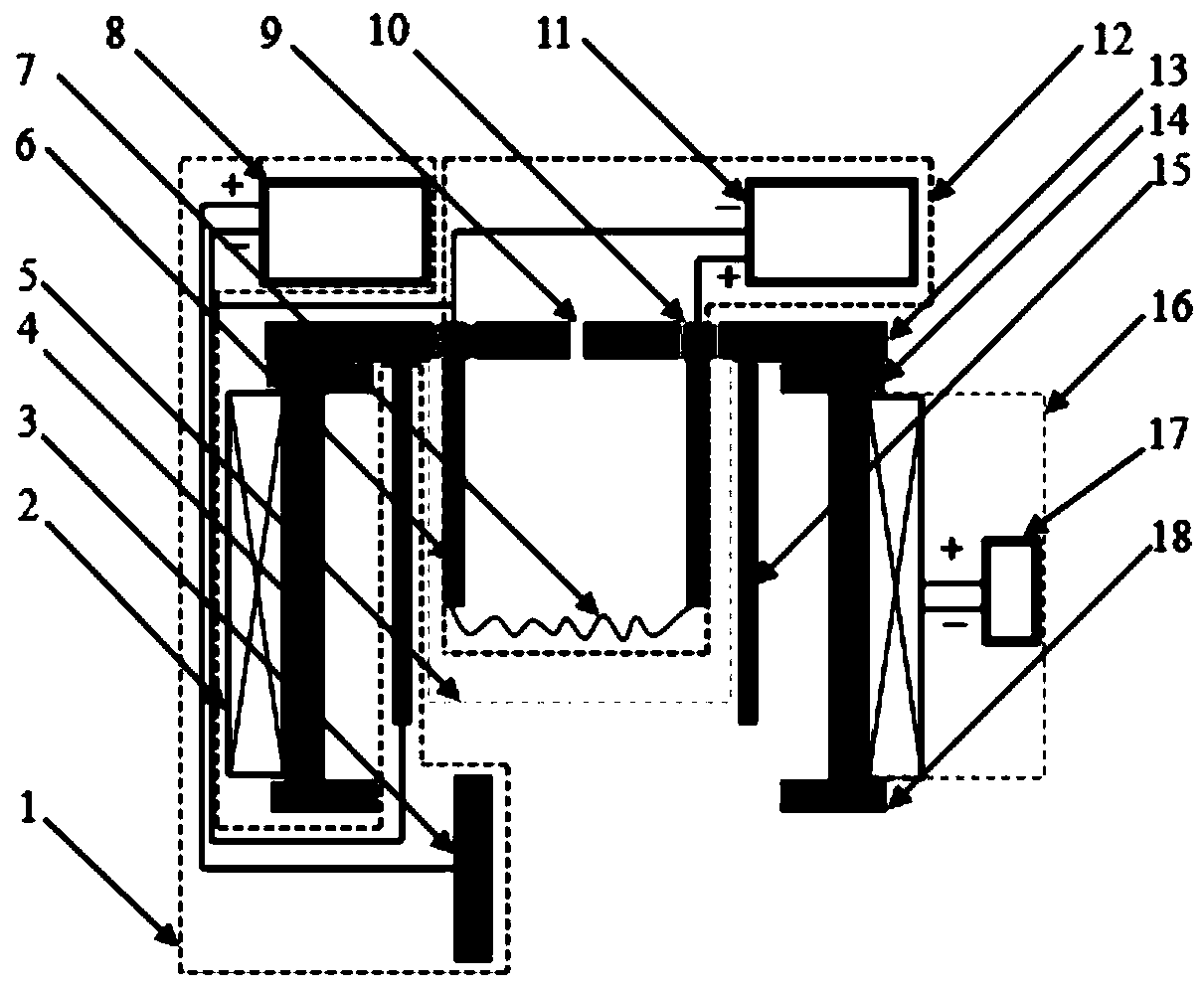

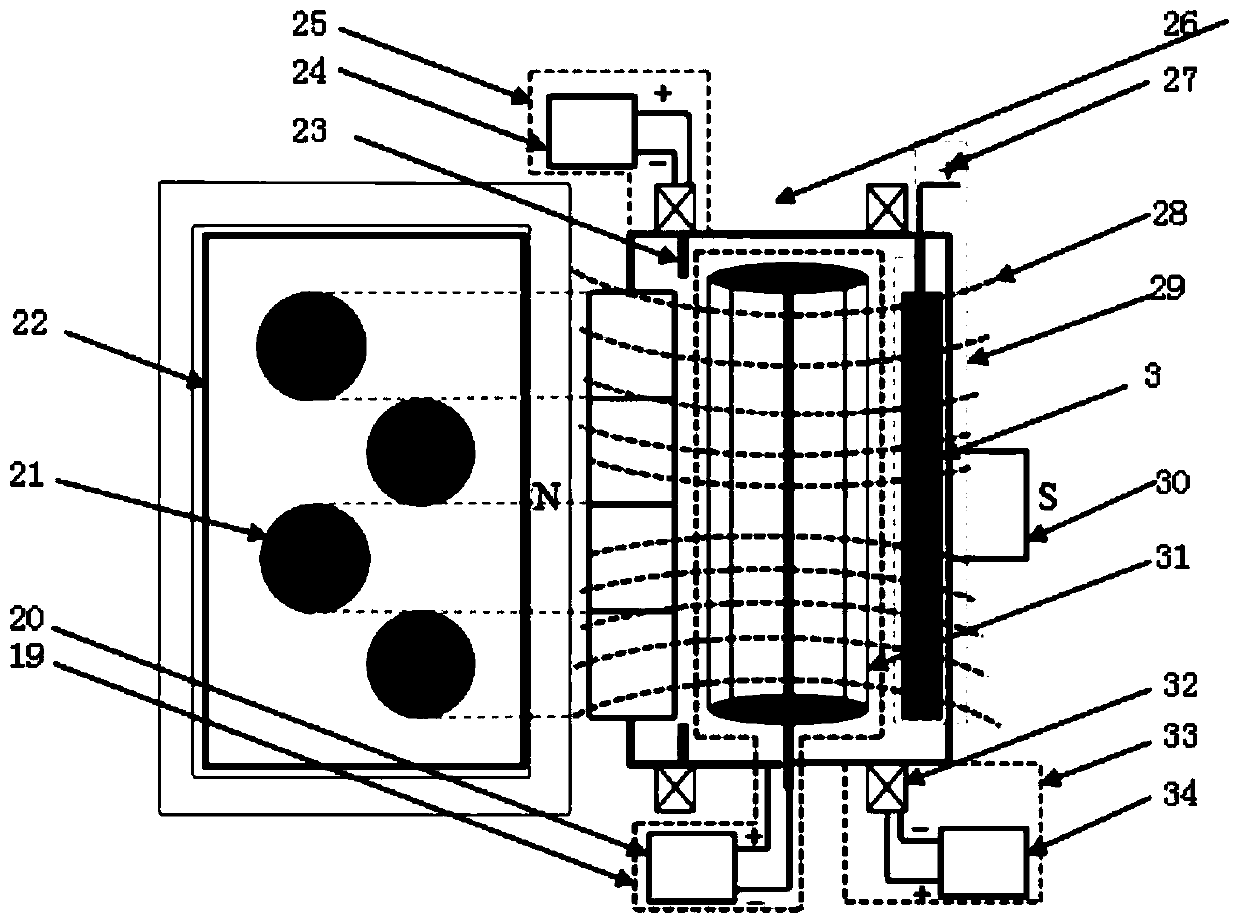

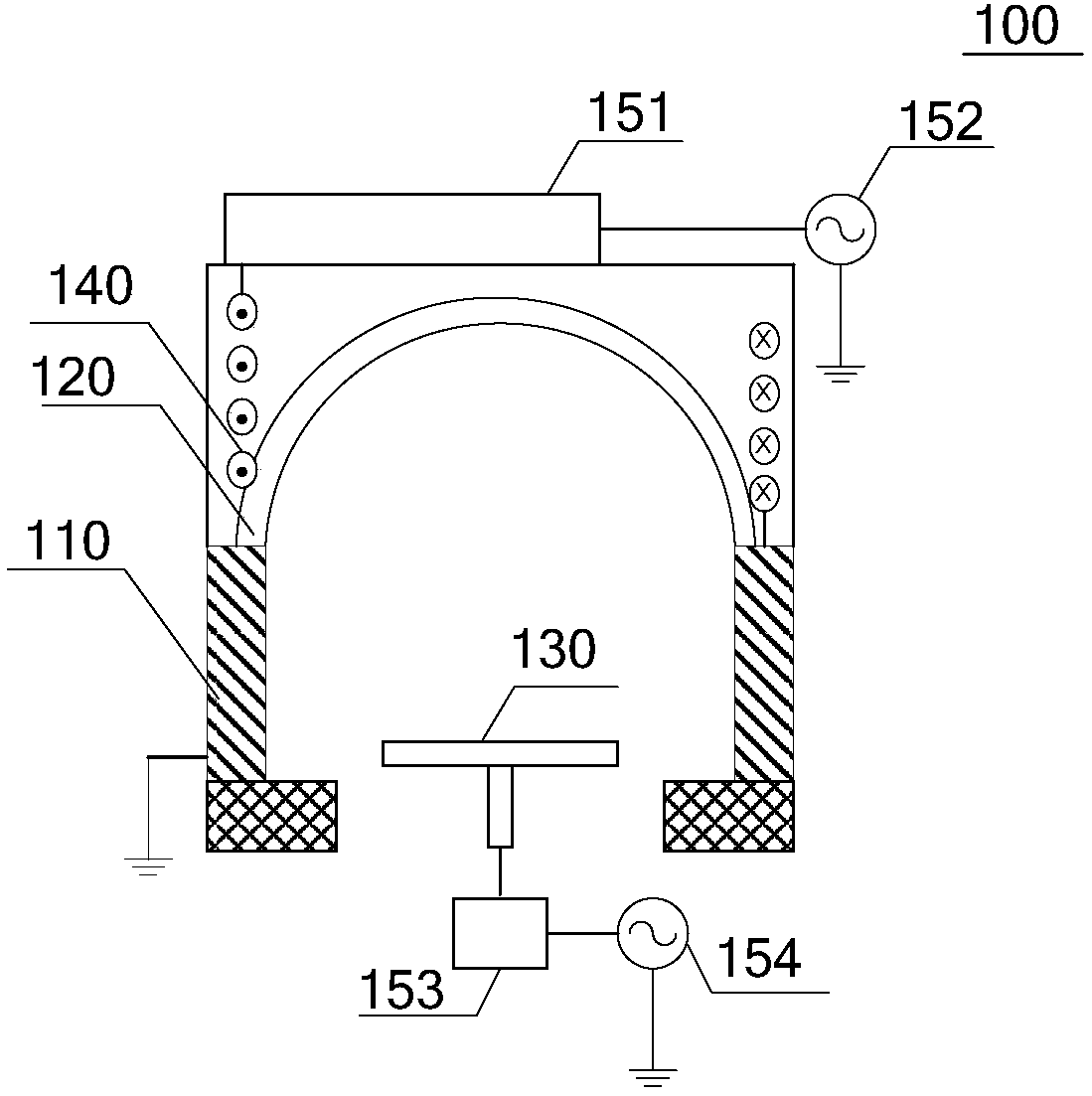

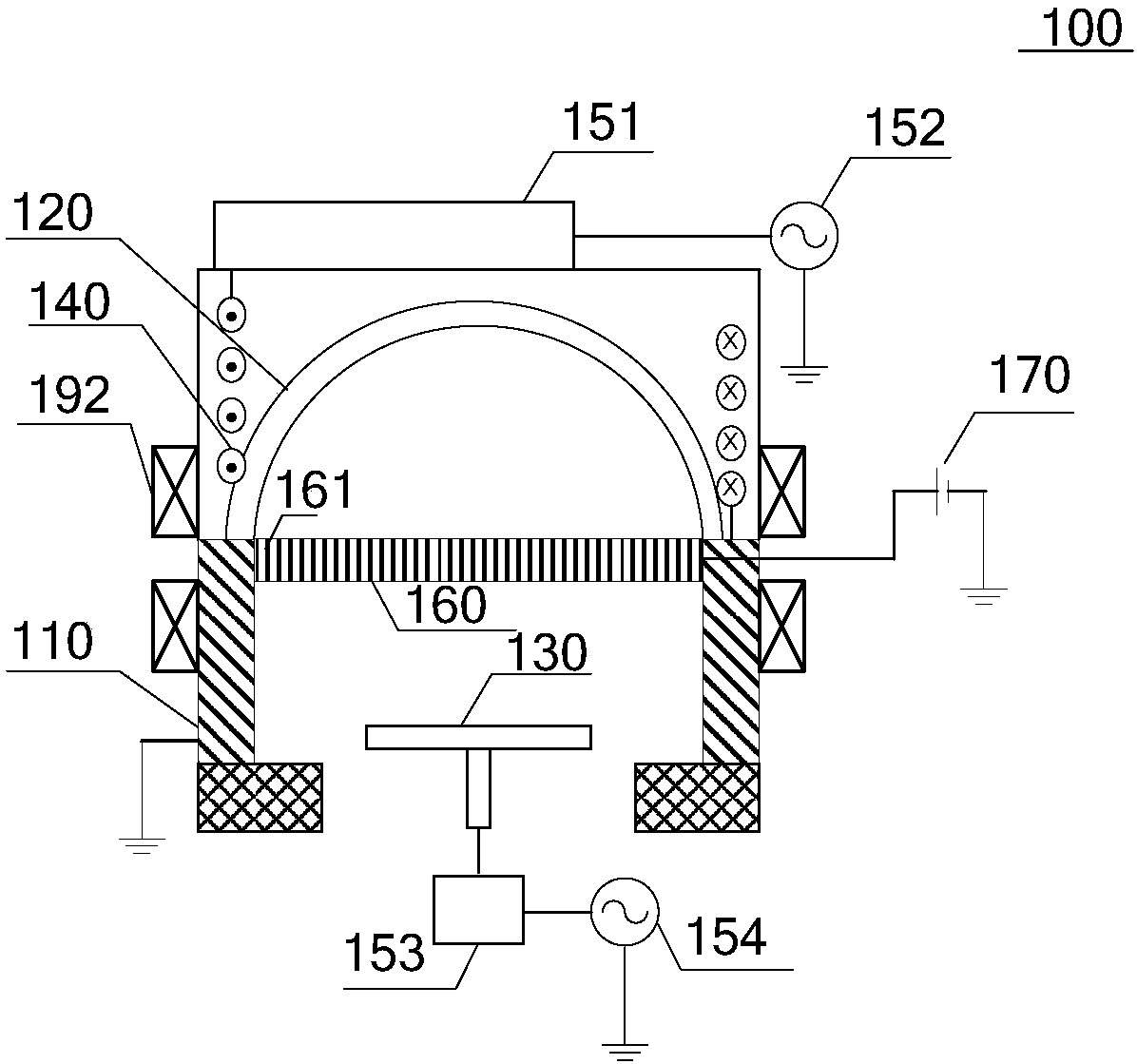

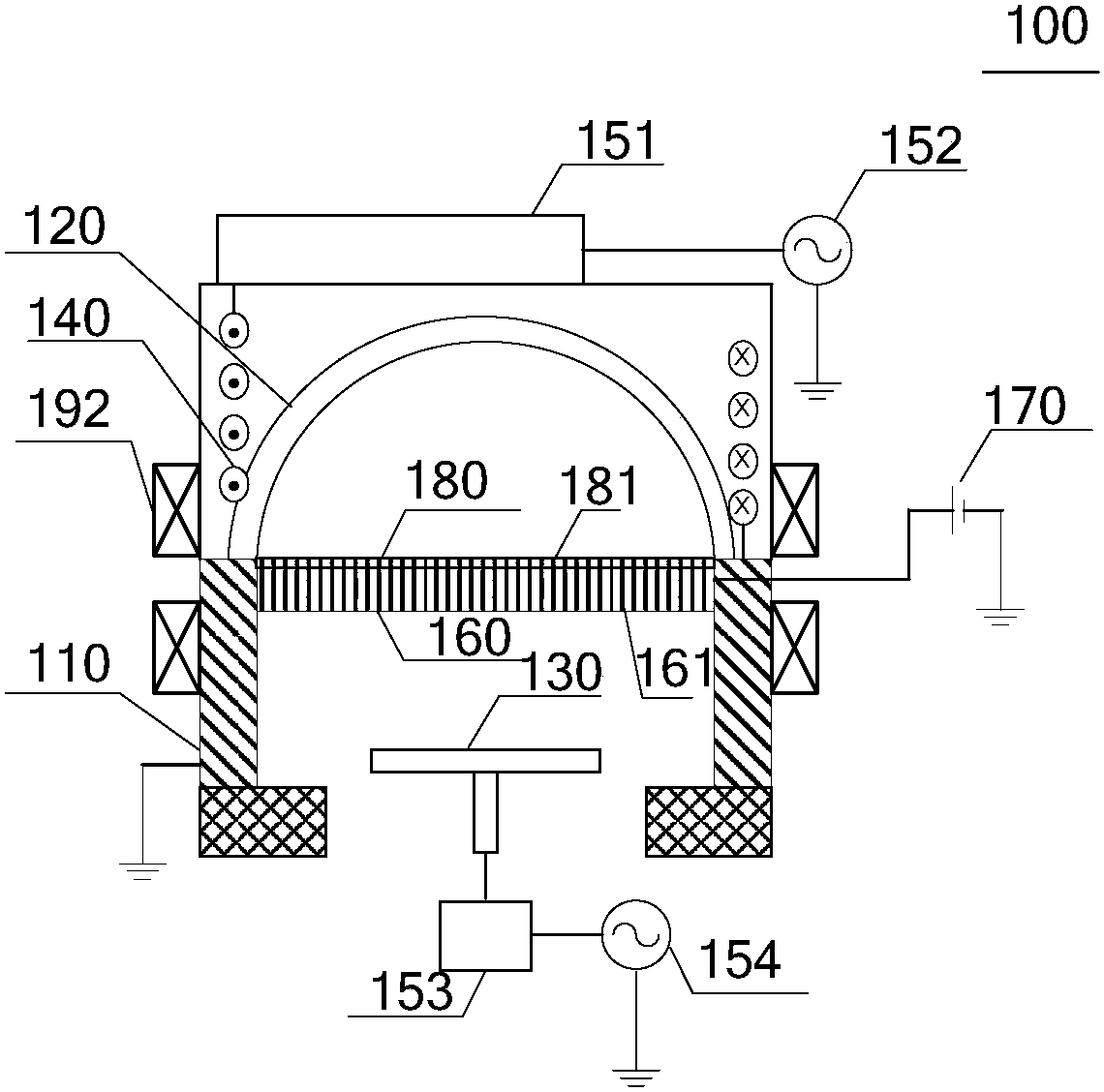

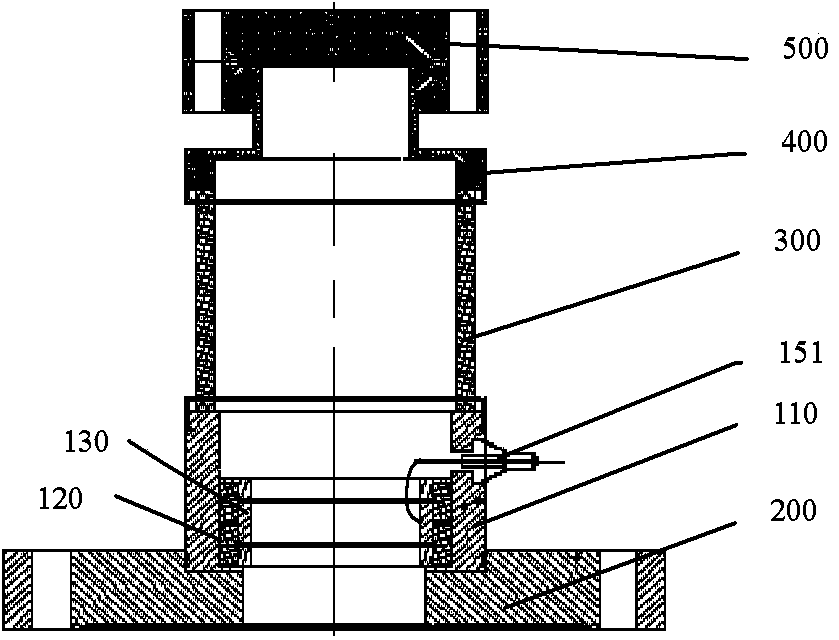

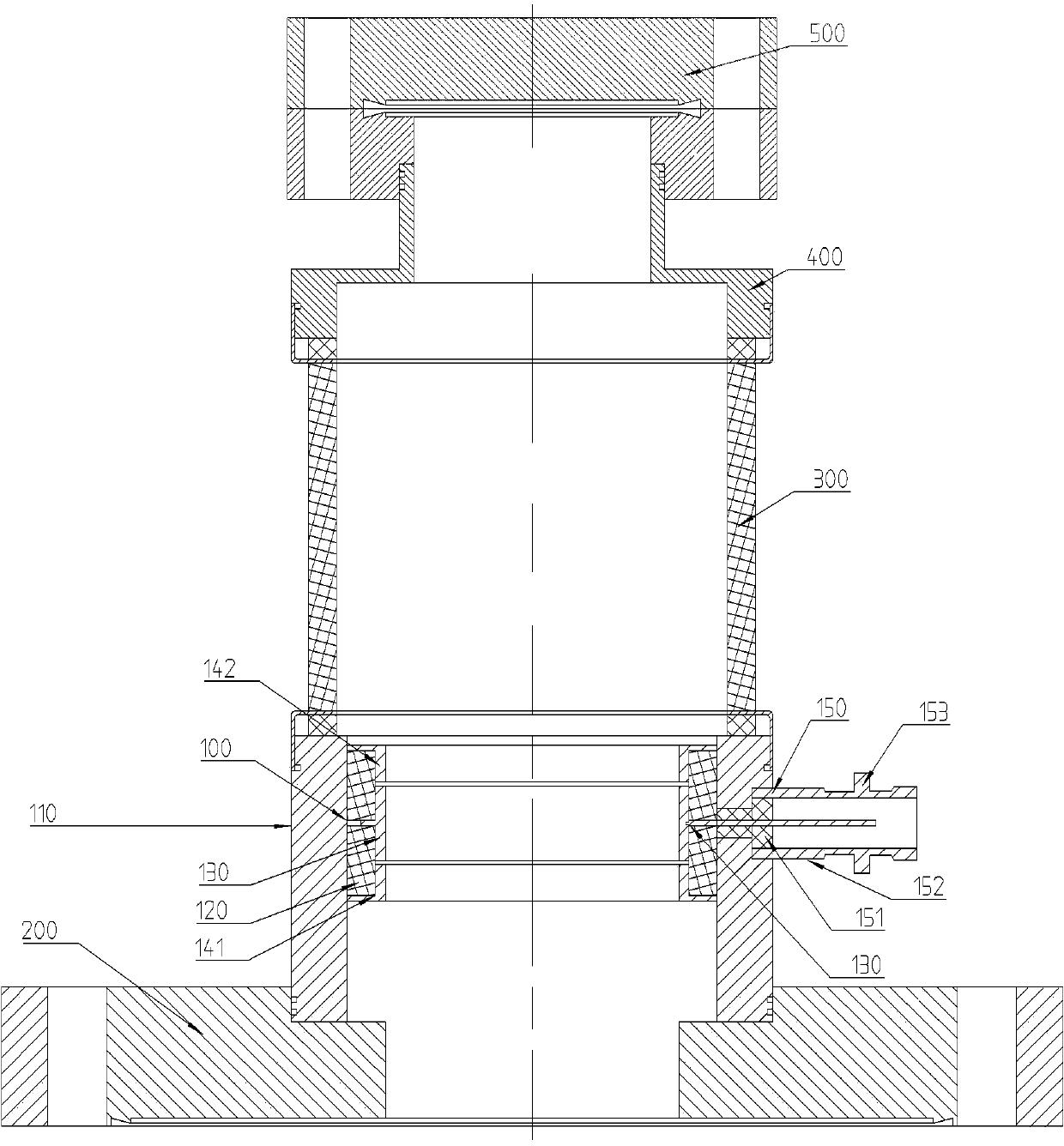

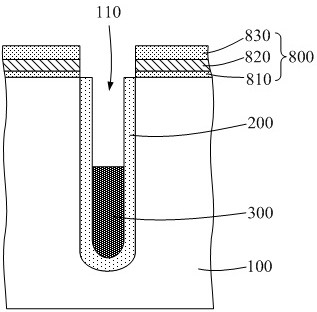

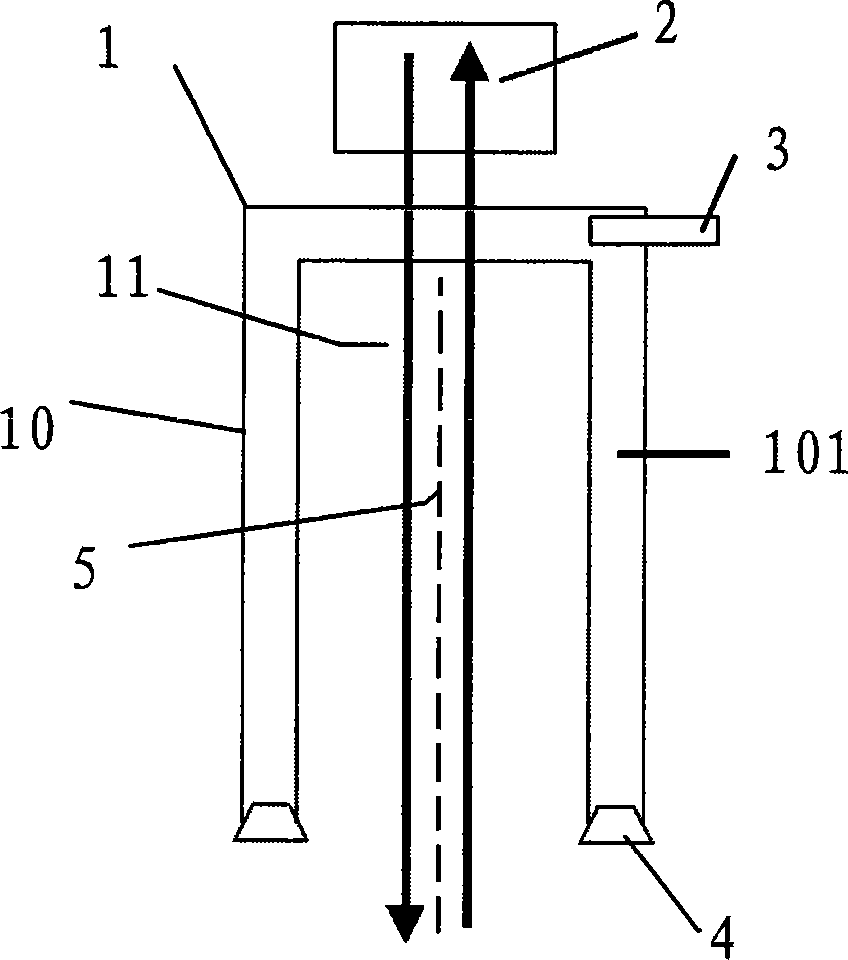

Gas arc discharge device, coupling system connected to vacuum cavity and ion nitriding process

PendingCN109943801AChange densityChange energySolid state diffusion coatingVolumetric Mass DensityVacuum chamber

The invention provides a gas arc discharge device, a coupling system of a vacuum cavity and an ion nitriding process. A thermal cathode electron emission principle is utilized to coordinate with an auxiliary cathode to generate plasma, and the plasma nitriding is carried out through coupling of a magnetic field module of the device and a cavity axial magnetic field module. The parameters of the gas arc discharge device and the cavity axial magnetic field are controlled to be coupled, the optimal magnetic field parameters are selected, the plasma energy and density in the vacuum cavity are increased, and the optimal nitriding effect is obtained. According to the device and the method, 316L austenitic stainless steel is subjected to 60 min plasma nitriding treatment, the hardness of a nitriding layer can reach 1100 HV0.05, the nitriding depth can reach 50 micron, no nitride is precipitated in the nitriding layer, and the nitriding layer is a single gamma N phase, so that the high hardness and high wear resistance of a nitriding workpiece are ensured.

Owner:泰安东大新材表面技术有限公司 +1

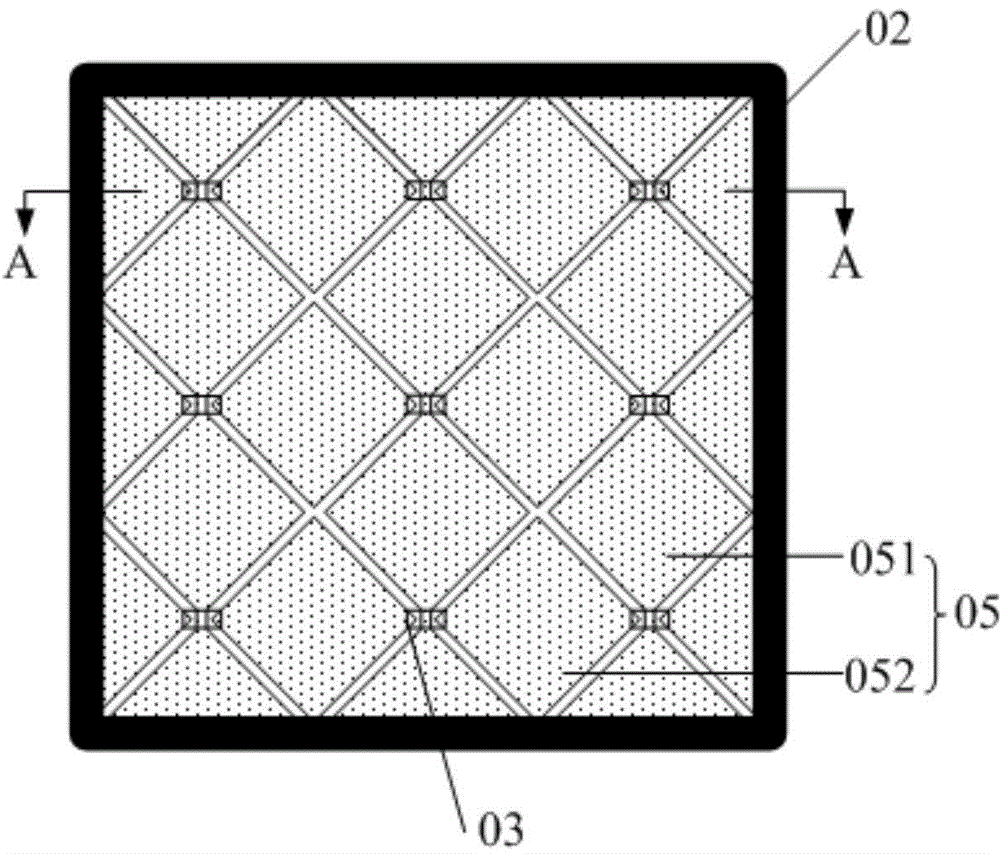

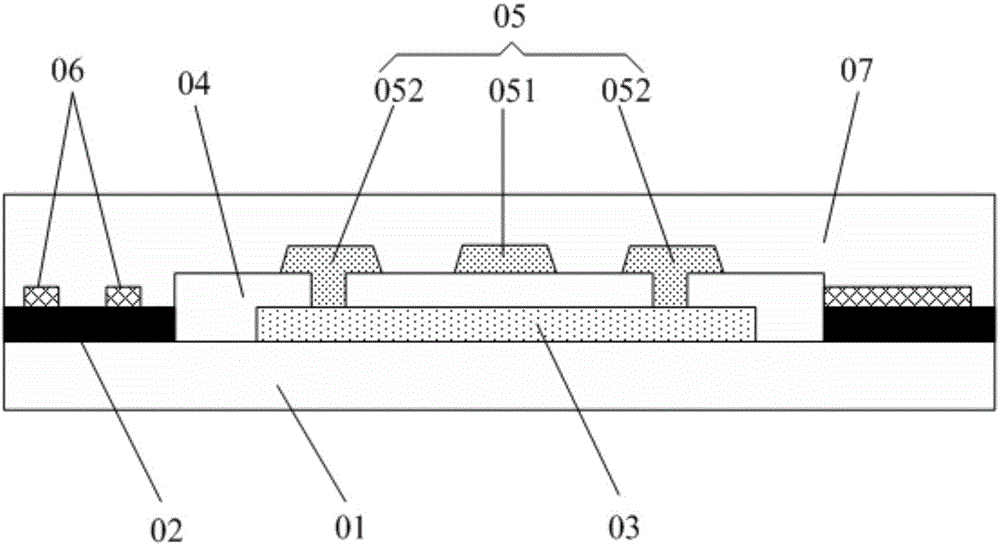

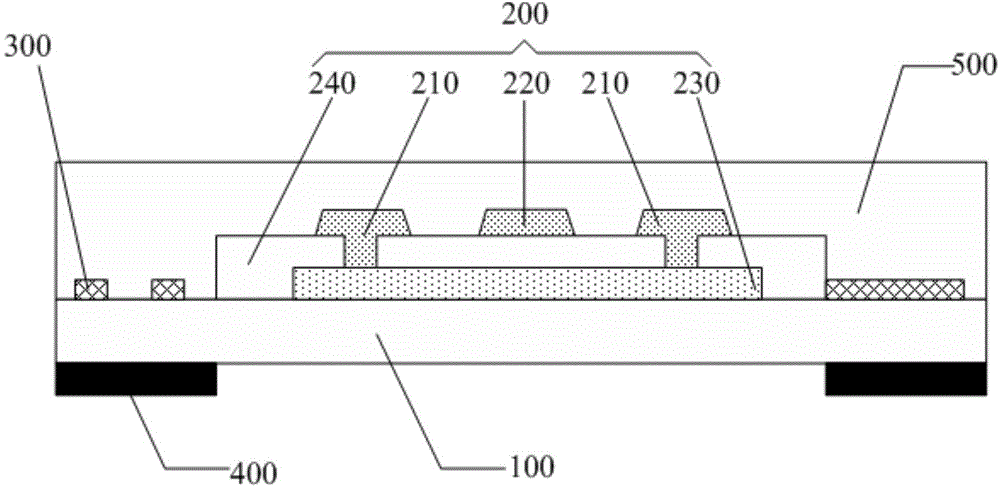

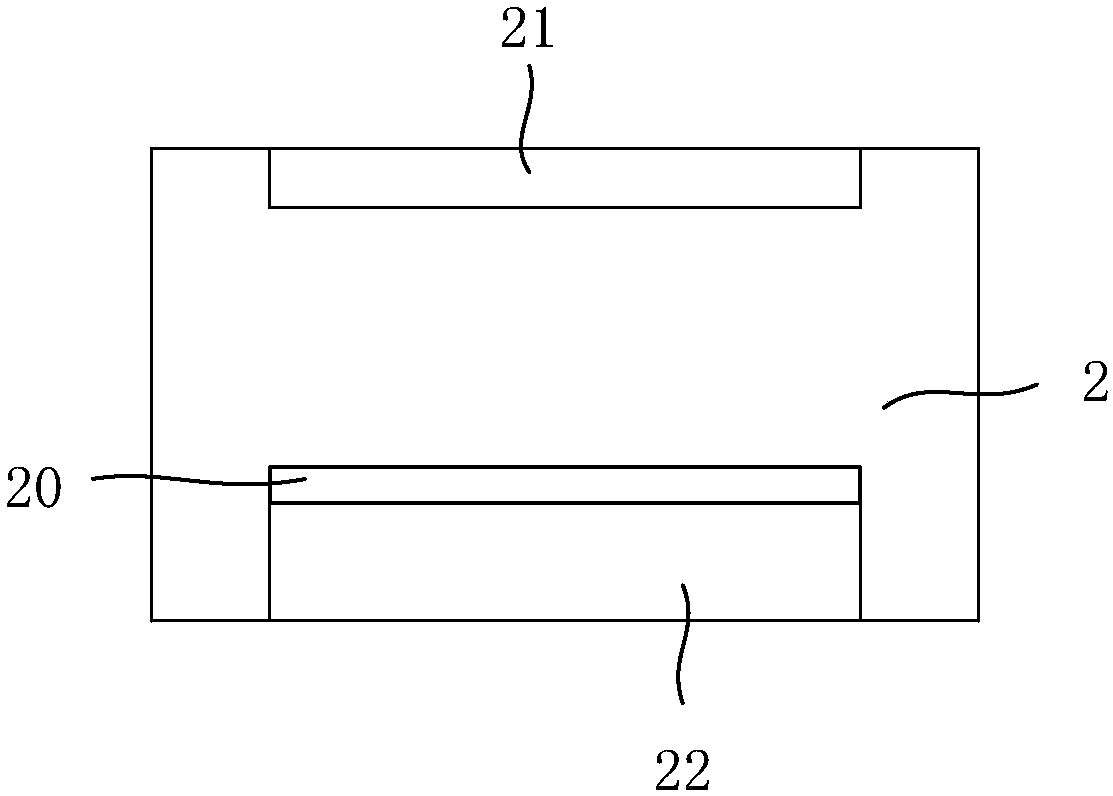

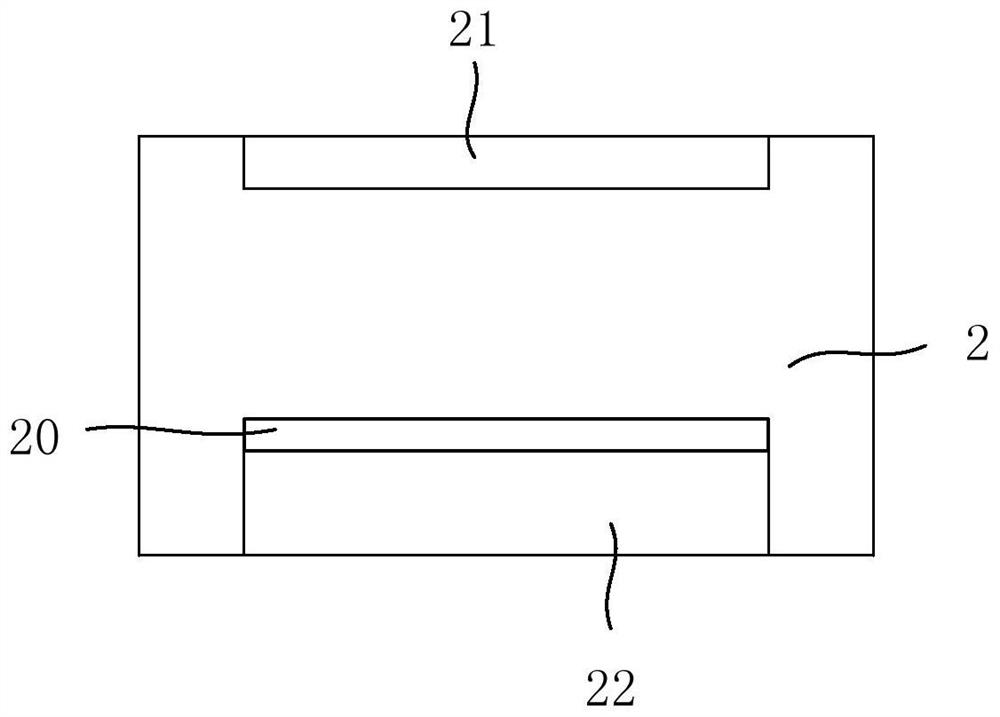

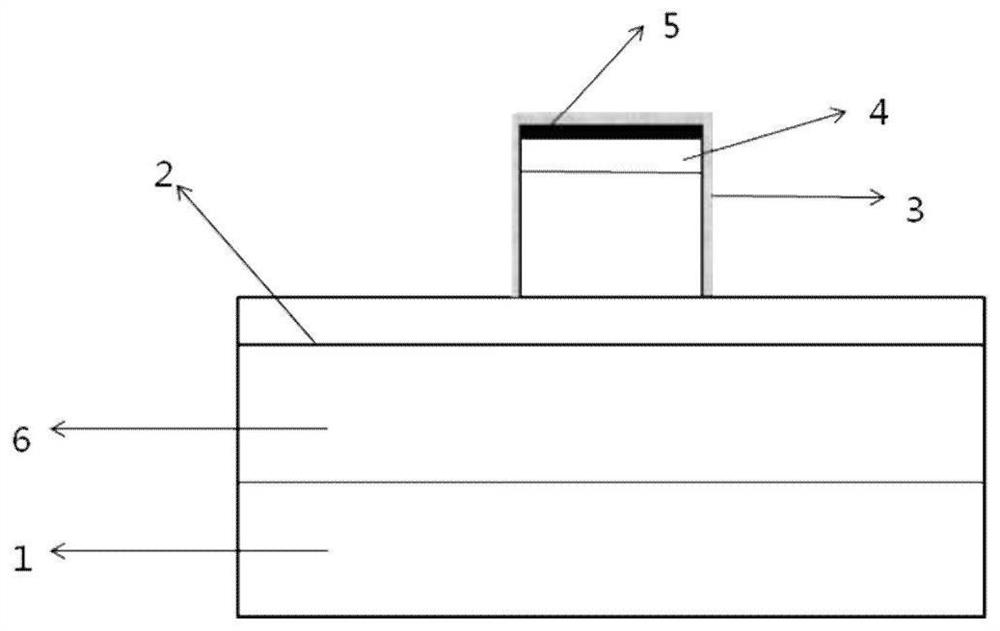

Touch screen, touch screen manufacturing method and display device

InactiveCN103914183AQuality assuranceAvoid pollutionInput/output processes for data processingDisplay deviceTouchscreen

The invention discloses a touch screen, a touch screen manufacturing method and a display device. Since a touch structure and peripheral lines are positioned on one side of a substrate while a shielding layer is positioned on the other side of the substrate, namely the shielding layer and the touch structure are positioned on two sides of the substrate respectively, when the touch structure and the peripheral lines are made on the substrate of the touch screen by means of sputtering, and the shielding layer on the other side of the substrate can be protected from strafing of plasmas in a sputtering cavity so as to be prevented from contaminating the cavity. In addition, due to the fact that the shielding layer is positioned on the other side of the substrate, compared with the prior art in which the touch structure and the peripheral lines are formed on a film layer of the shielding layer, the touch screen, the touch screen manufacturing method and the display device have the advantages that the problem of unevenness of the touch structure resulted from unevenness of the shielding layer is avoided, and quality of the touch screen is guaranteed.

Owner:BOE TECH GRP CO LTD

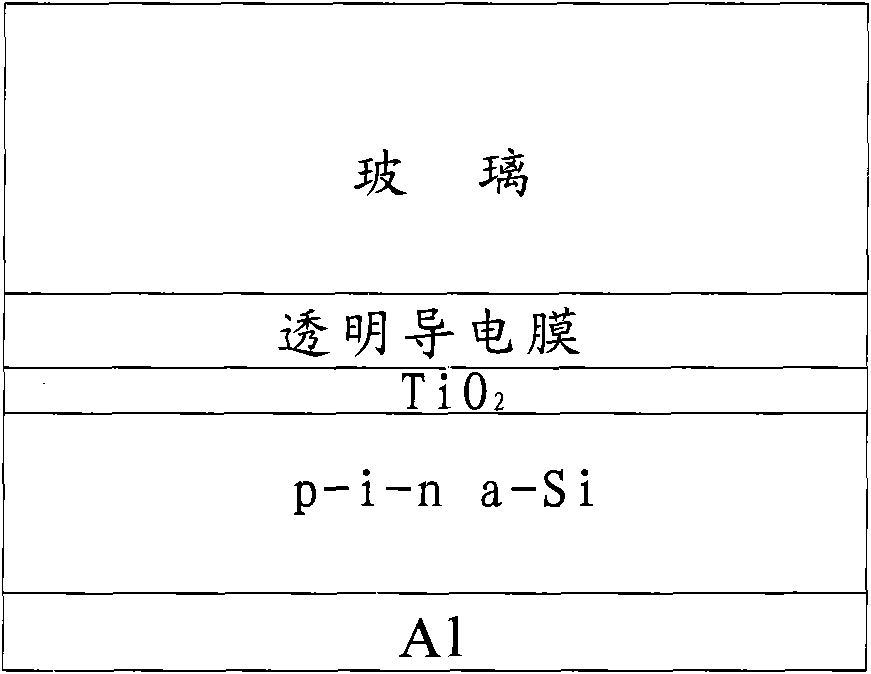

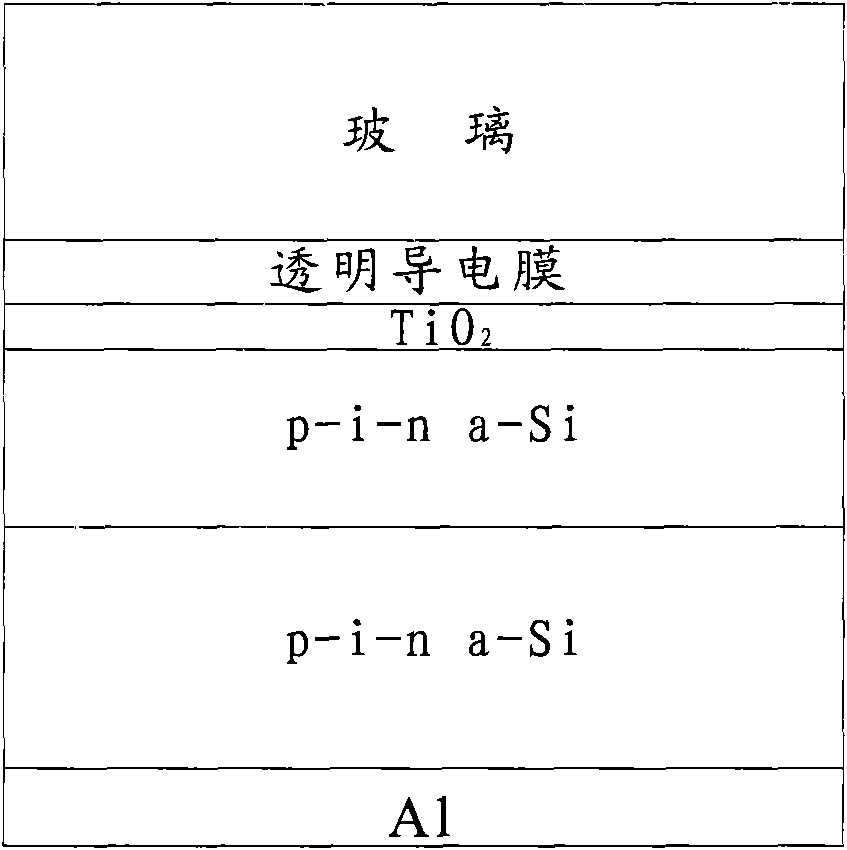

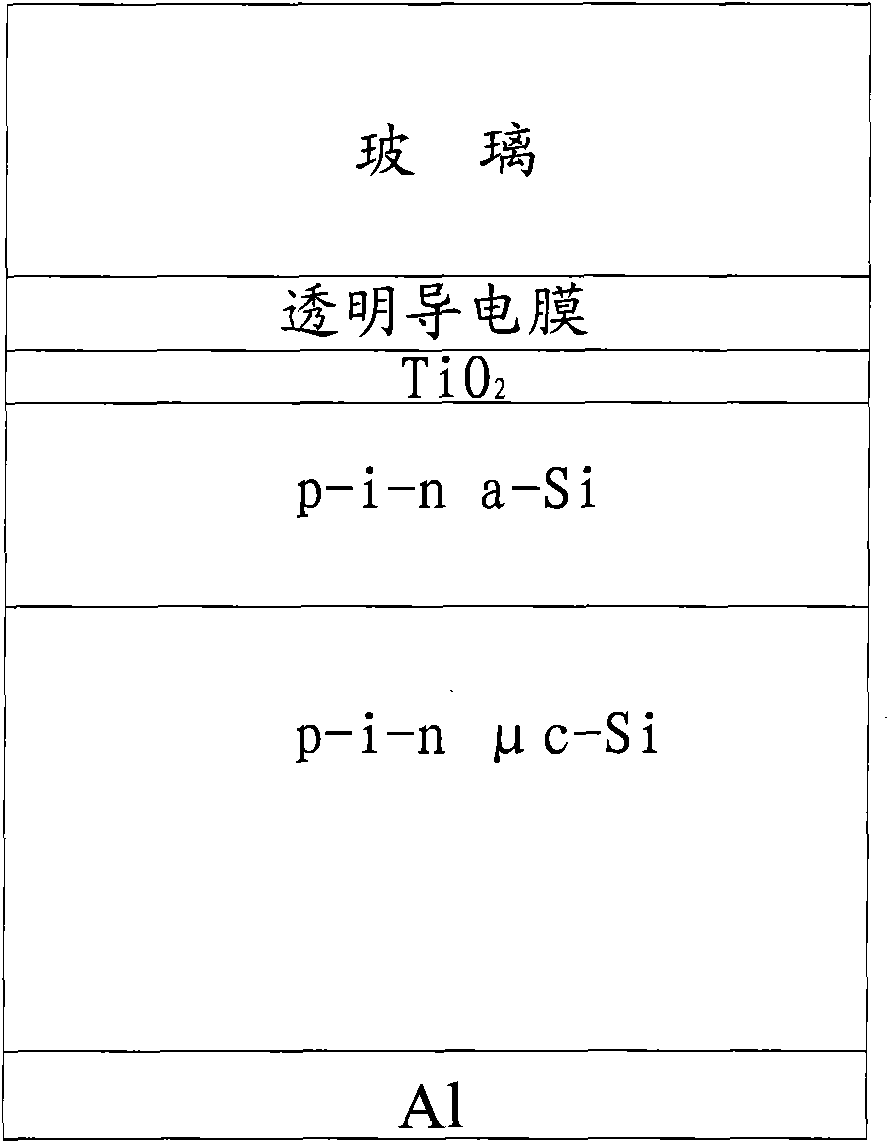

Method for preparing titania film by using gas flow reaction sputtering under middle gas pressure and method for preparing solar cell

InactiveCN101838794AImprove thermal stabilityIncreased chance of collisionVacuum evaporation coatingSputtering coatingSuperoxideHigh energy

The invention discloses a method for preparing a titania film by using gas flow reaction sputtering under a middle gas pressure and a method for preparing a solar cell. The preparation method for the titania film comprises the following steps of: A), placing a glass substrate plated with a transparent conducting film into a reaction chamber of vacuum sputtering coating equipment and vacuumizing the reaction chamber; and B), introducing a working gas into a target chamber between a pair of titanium targets which is oppositely arranged in a cathode device of the vacuum sputtering coating equipment, and introducing oxygen outside the target chamber, wherein the sputtering gas pressure of the working gas is 10 to 100 Pa, and a TIO2 film is formed on the transparent conducting film by sputtering deposition. The method improves the sputtering gas pressure, and prevents high-energy superoxide anions O- and neutral argon particles from bombarding the substrate so as to reduce crystal defects and improve the electrical conductivity and the thermal stability of the TIO2 film.

Owner:苏州羿日新能源有限公司

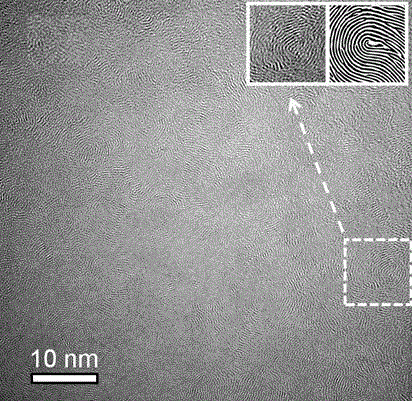

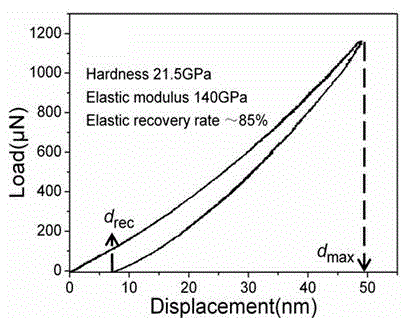

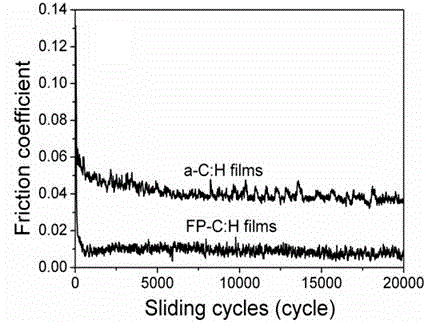

Low-temperature vapor deposition method for carbon-based super-lubricating thin film with onion structure

ActiveCN105779950AImprove mechanical propertiesUniform mechanical propertiesVacuum evaporation coatingSputtering coatingAlcoholPhysical chemistry

The invention relates to a low-temperature vapor deposition method for a carbon-based super-lubricating thin film with an onion structure. The method comprises the following steps of (1) carrying out ultrasonic cleaning on silicon substrate by using acetone and absolute ethyl alcohol, and transferring the silicon substrate to a coating cavity; (2) vacuumizing until the vacuum degree is smaller than 4.0*10<-3> Pa; (3) cleaning under the following conditions: introducing Ar until the air pressure is 2-3 Pa, applying a negative bias voltage of -1000 to -1200 V to the silicon substrate to carry out plasma glow cleaning for 10 min; and (4) depositing the carbon-based super-lubricating thin film with the onion structure, namely keeping the bias voltage at -500 to -1000 V, the frequency at 3.5 KHz and the duty ratio at 15-25%; and keeping the air flow of Ar at 80-200sccm, the CH4 flow at 40-50sccm, the air pressure at 0.45-0.5 Pa, the target power at 800-900 W, the deposition time within 1 h and the deposited thin film thickness at about 1 mu m in the deposition process. The carbon-based super-lubricating thin film with the onion structure, prepared by using the low-temperature vapor deposition method, has the advantages of high hardness, excellent chemical inertness, low frictional coefficient, good wear resistance and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

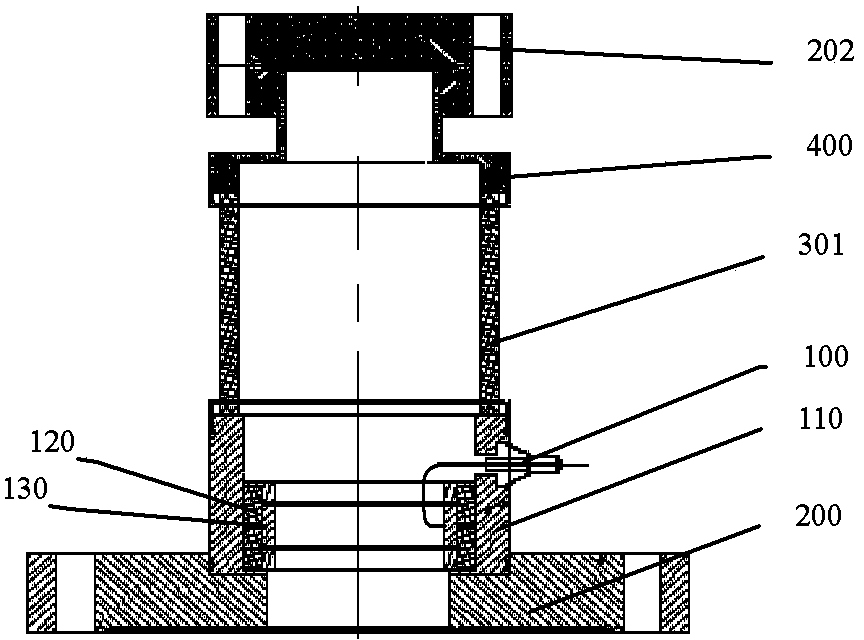

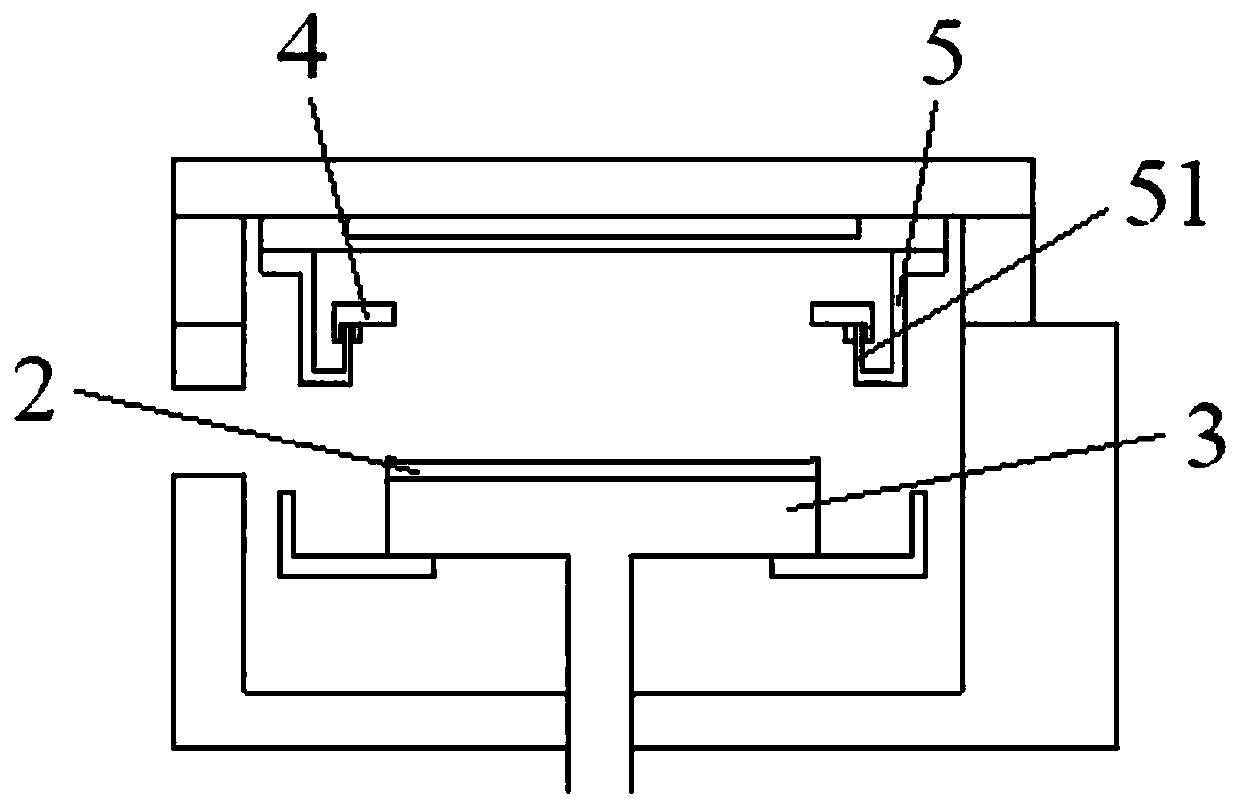

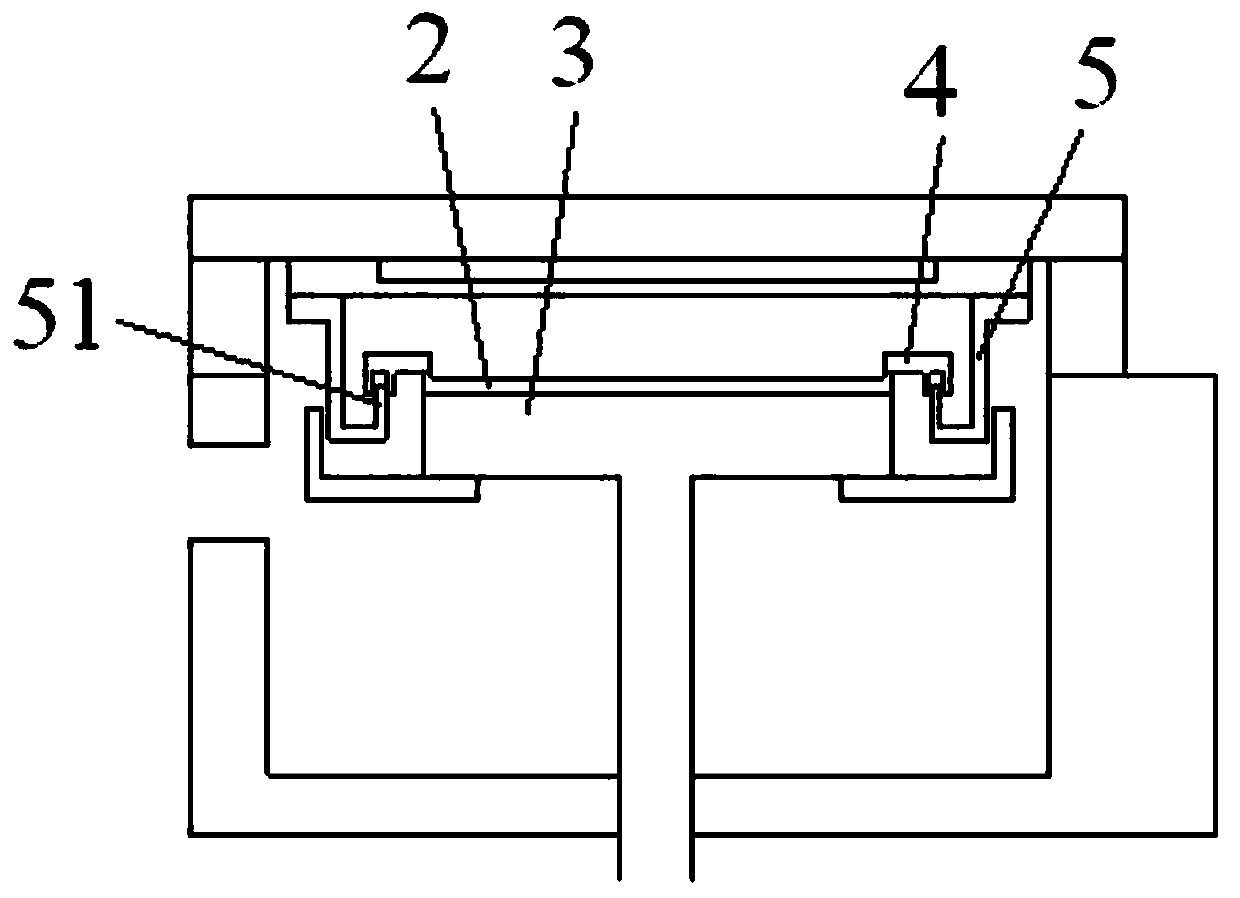

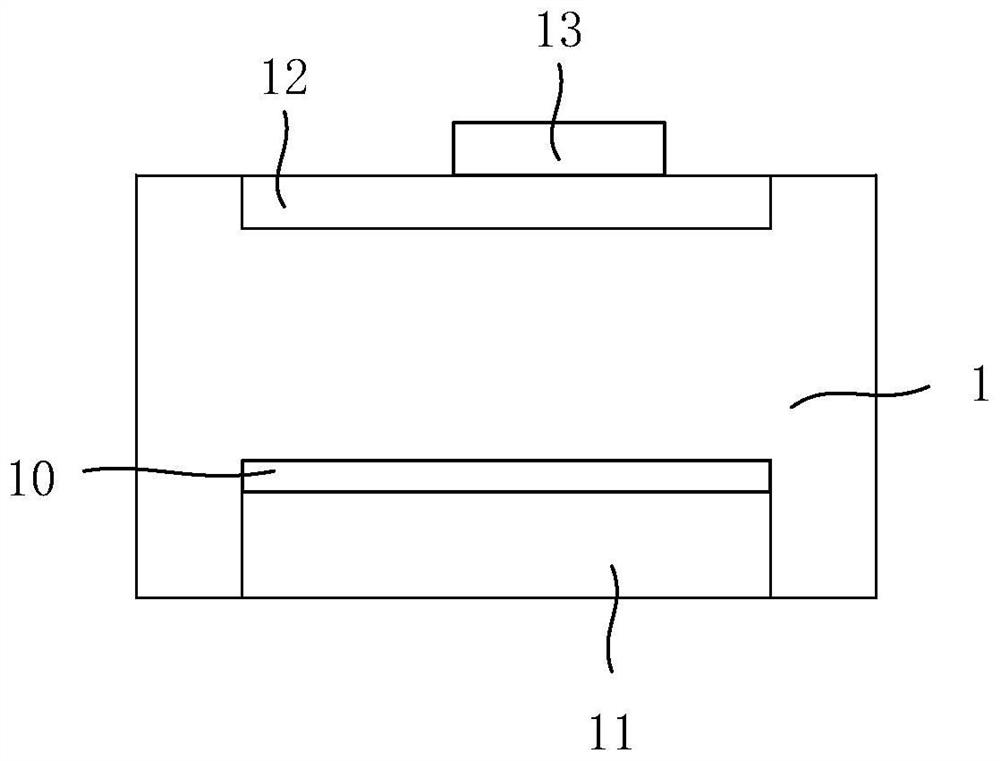

Pre-cleaning cavity and semiconductor processing device

ActiveCN109390197AWeaken the kinetic energy of the bombardmentWon't happenElectric discharge tubesFinal product manufactureEngineeringSemiconductor

The present invention discloses a pre-cleaning cavity and a semiconductor processing device. The pre-cleaning cavity comprises a cavity, a top cover, a bearing piece and a metal plate. The top cover is arranged at the top end of the cavity and is configured to seal the cavity, the bearing piece is arranged at the bottom portion of the cavity and configured to bear a wafer, the metal plate is horizontally arranged between the bearing piece and the top cover and is provided with a plurality of first vent holes penetrating the thickness of the metal plate, the metal plate is earthed to filter outions in plasmas, the plasmas form a plasma sheath at the surface of the metal plate, the pre-cleaning cavity further comprises an insulation protection plate arranged between the metal plate and thetop cover, the insulation protection plate is provided with a plurality of second vent holes penetrating the thickness of the insulation protection plate, and the insulation protection plate can prevent ions from bombarding the surface of the metal plate under the drive of the voltage of the plasma sheath. The pre-cleaning cavity can effectively reduce the metal ion pollution of the surface of thewafer and can improve the yield of the wafer cleaning.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

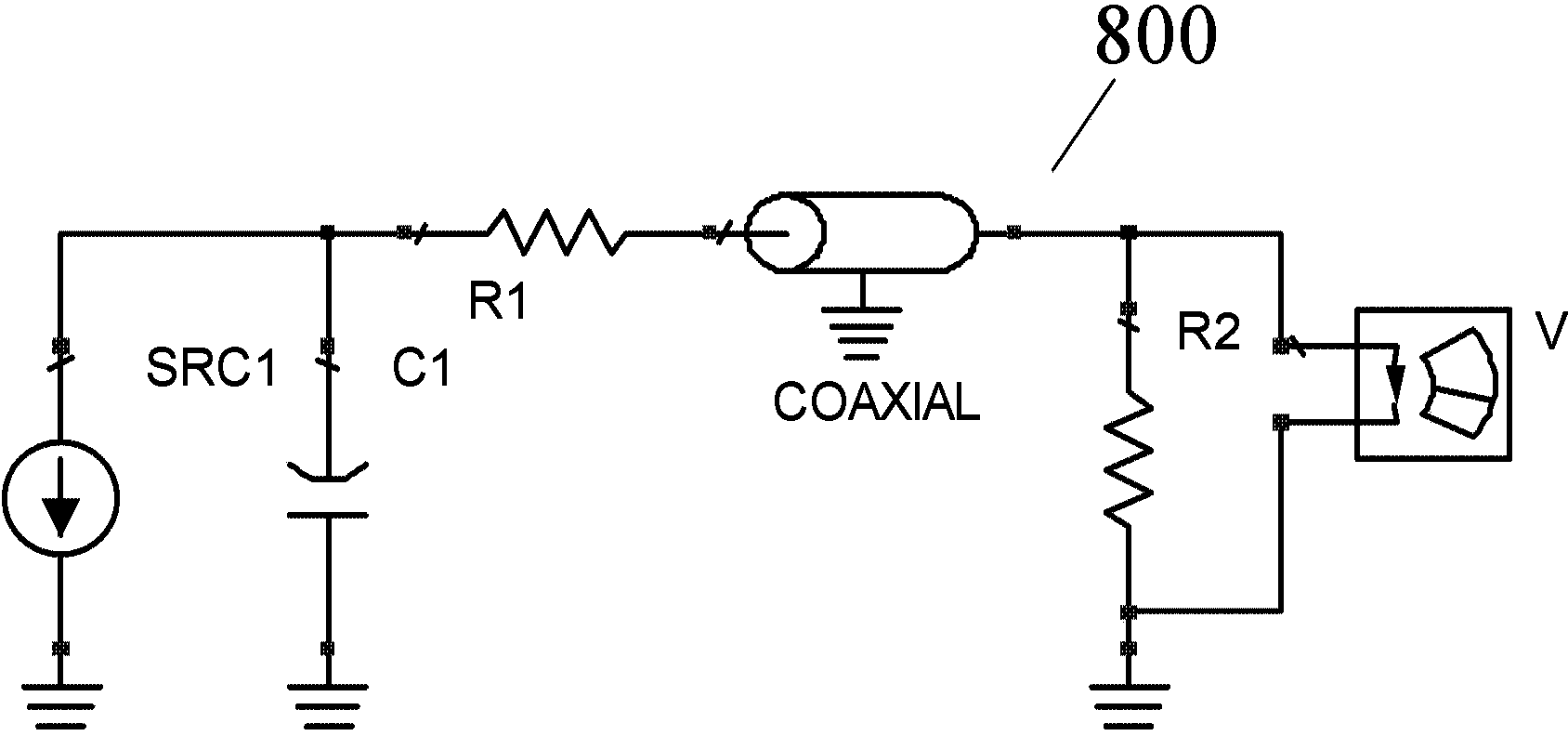

Electronic beam axial velocity measurement system

InactiveCN103794449APrevent escapeReduce electric field distortionElectric discharge tubesMeasurement deviceMeasurement precision

The invention provides an electron beam axial velocity measurement system which comprises a capacitive probe device, a collector cavity structure, a voltage integral and transmission circuit, a voltage measurement device and a current measurement device. The capacitive probe device comprises a main cavity structure and an electron beam induction ring; the collector cavity structure is communicated with the main cavity structure and is in a shape of a spindle with a large middle and two small ends; the front end of the voltage integral and transmission circuit is electrically connected to the electron beam induction ring and used for converting inductive charge generated when electron beams penetrate through a capacitive probe into voltage signals; the voltage measurement device is electrically connected to the rear end of the a voltage integral and transmission circuit; the current measurement device is electrically connected to the collector cavity structure. By means of the electron beam axial velocity measurement system, influence of stray electrons during measurement is reduced, and measurement precision of electron beam axial velocity is increased.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

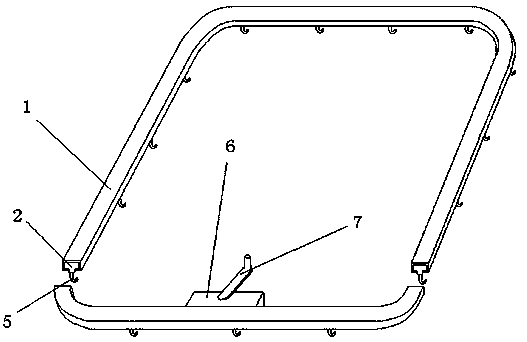

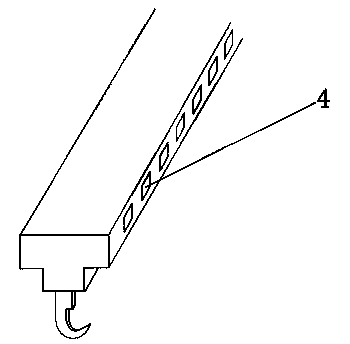

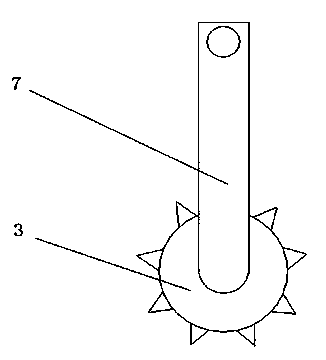

Annular clothes hanger

The invention discloses an annular clothes hanger which comprises an annular hollow frame, an annular crawler belt and a rotating gear. The annular frame is hollow, an annular through hole guide rail is arranged at the middle position of the bottom end of the annular hollow frame, the annular crawler belt is in a T-like shape, the annular crawler belt is located in the annular hollow frame, a plurality of gear grooves are formed in the inward side edge of the annular crawler belt, and hooks are arranged at the bottom ends of the annular crawler belt. A gear box is arranged on the side edge of the annular hollow frame, the rotating gear driving the annular crawler belt to slide is arranged in the gear box, and a rotating handle used for driving the rotating gear to rotate is arranged on the gear box. Compared with the prior art, clothes airing forks are no more needed by the annular clothes hanger, clothes can be put on the clothes hanger with bare hands for airing, and the annular clothes hanger is more simple, more practical and safer.

Owner:SUZHOU SHENGNENG MACHINERY

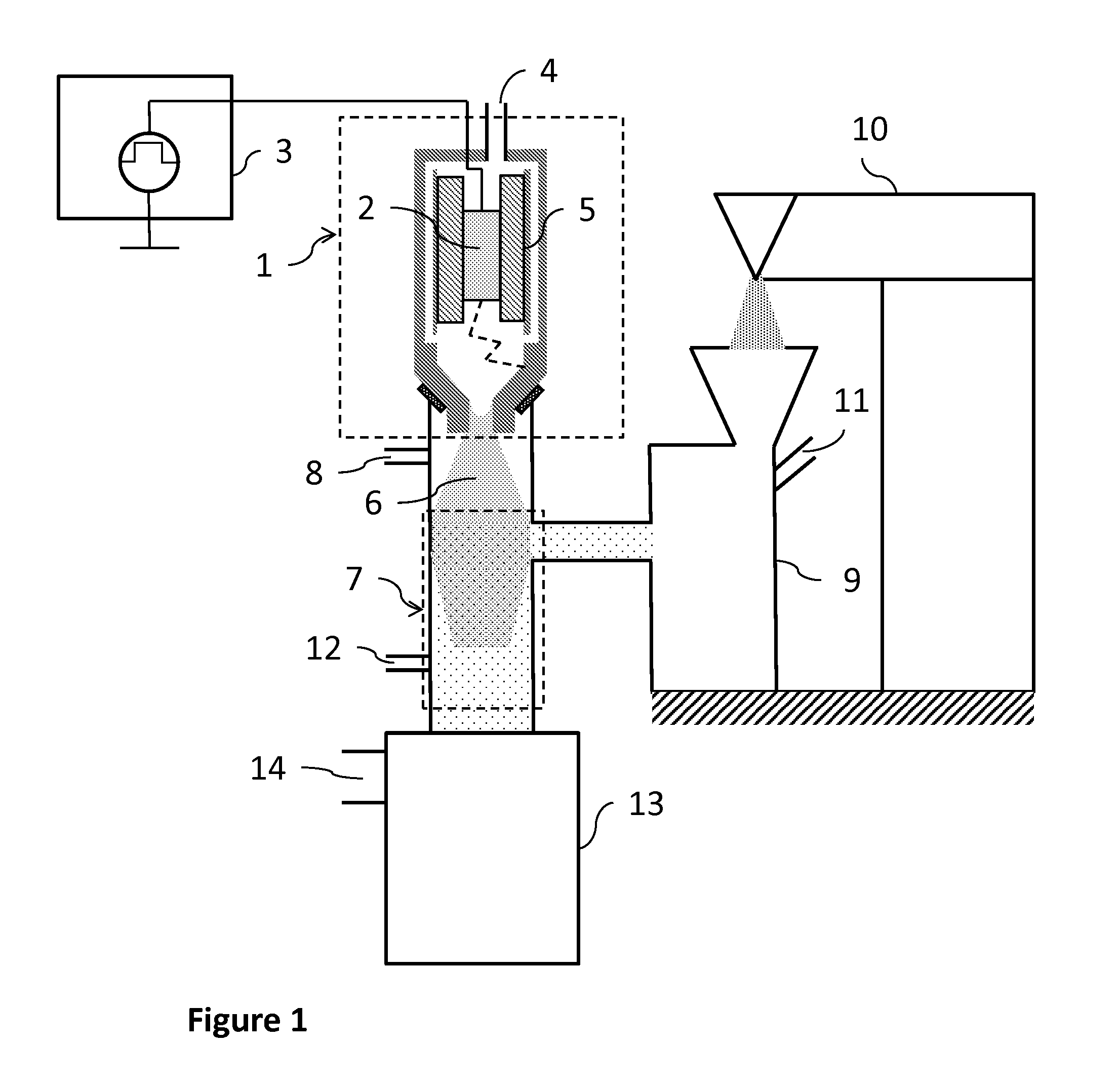

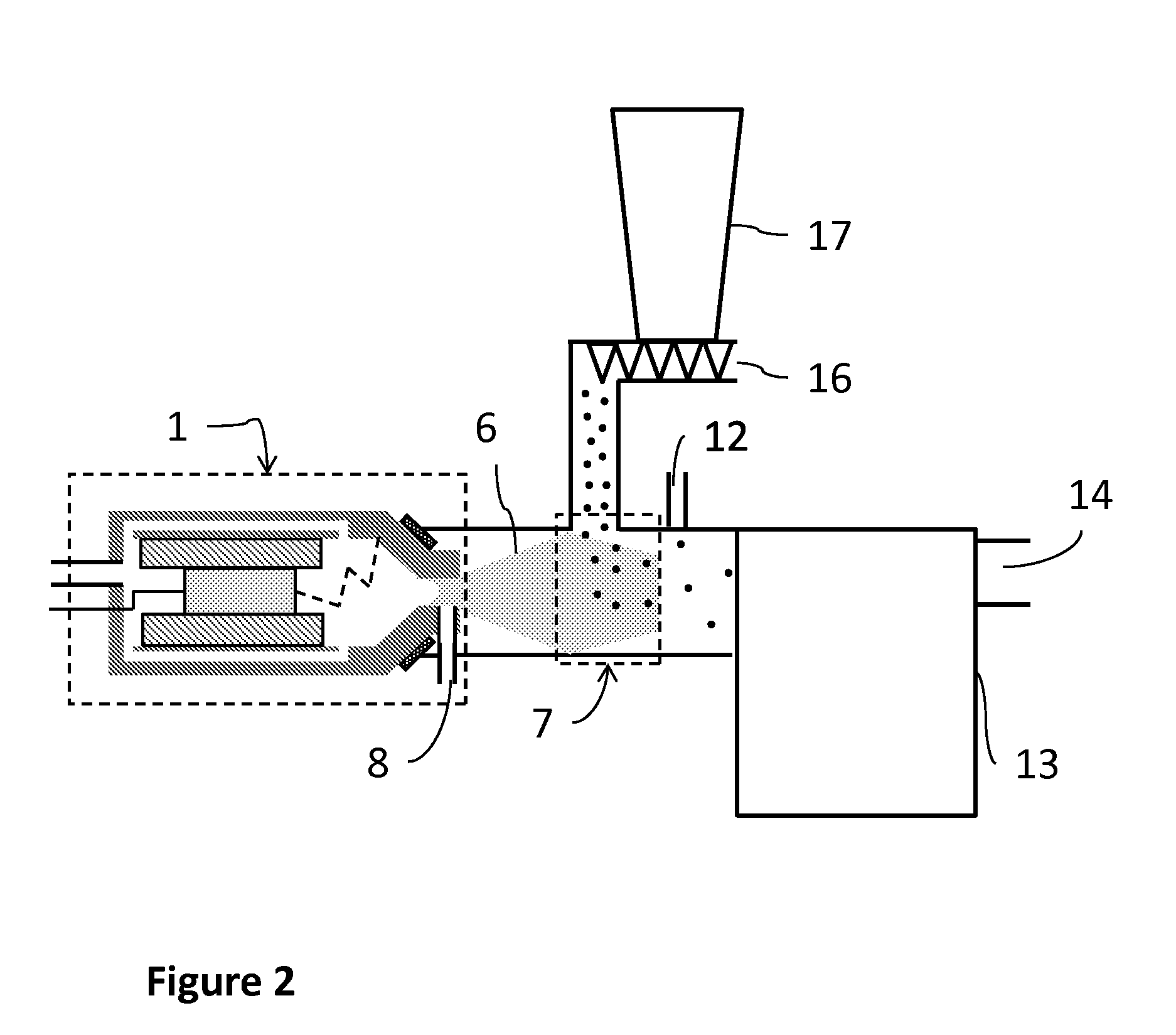

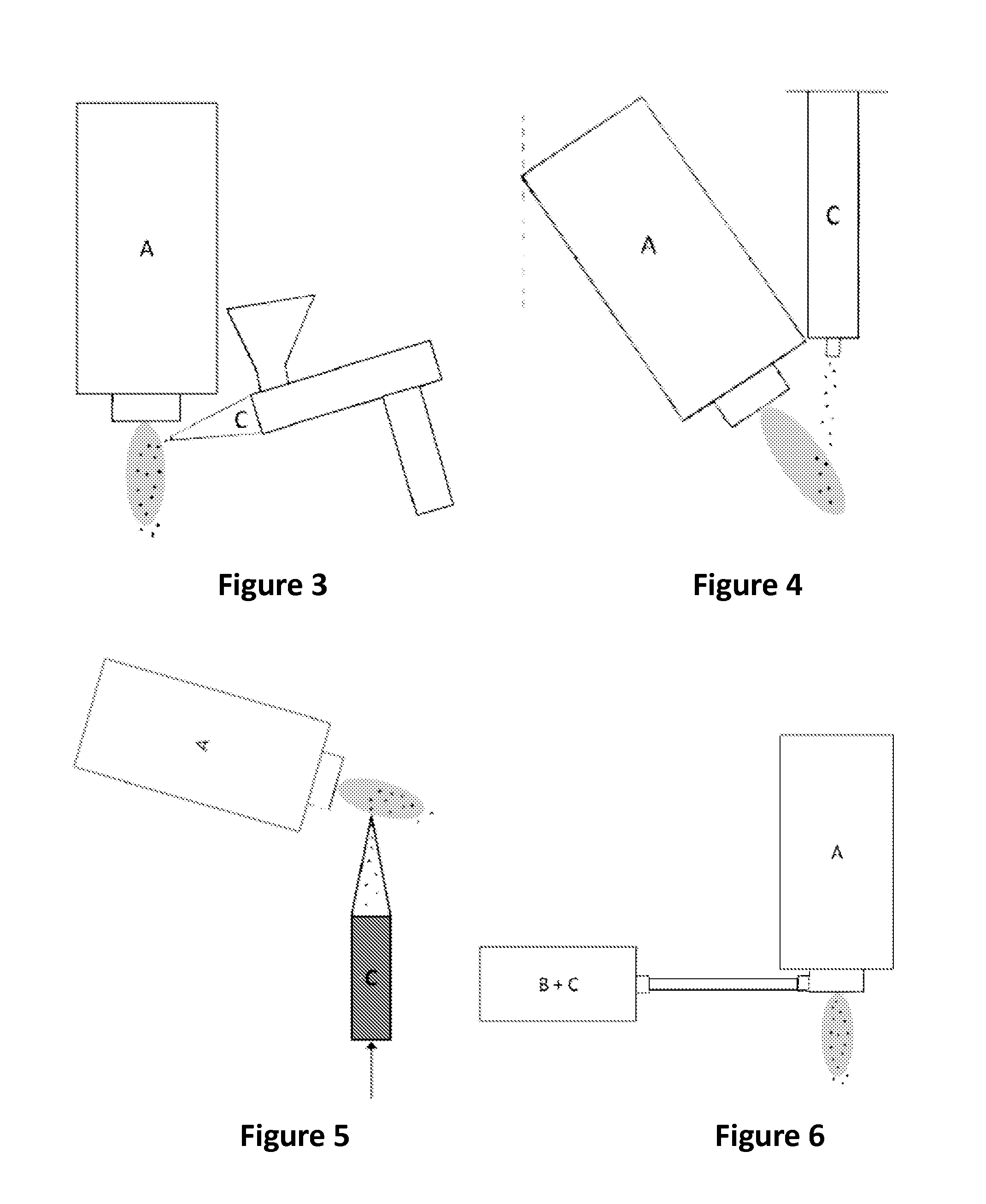

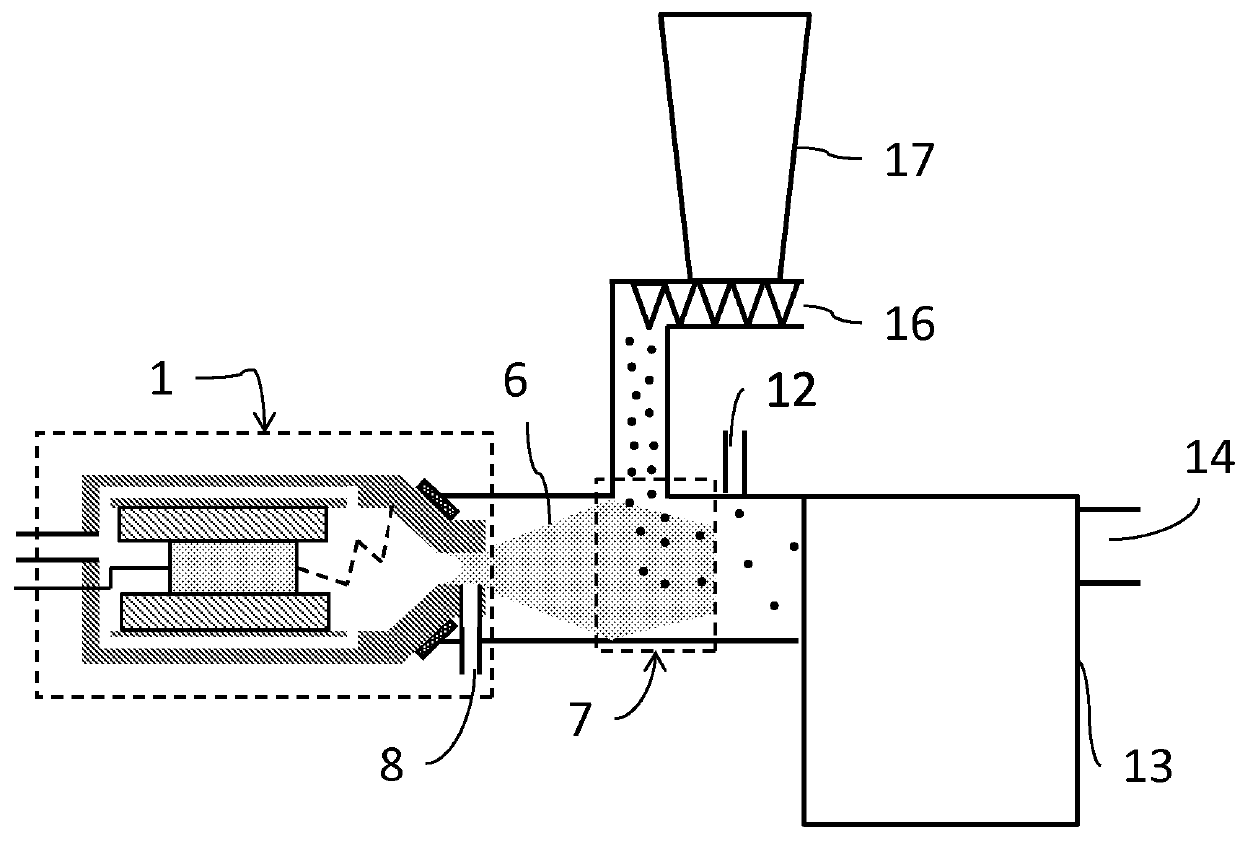

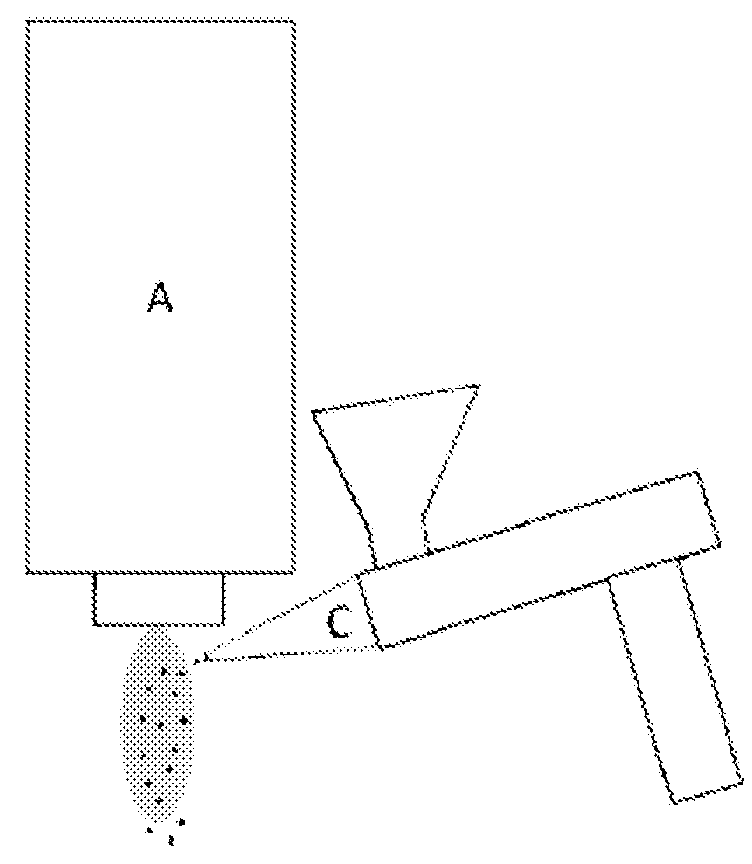

Method and Apparatus for Surface Chemical Functionalization of Powders and Nanoparticles

ActiveUS20160039979A1Uniform surface finishImprove material performanceChemical speciesChemical reaction

A method and apparatus is provided for the modification of the surface chemistry of solid nano- and micro-particles in order to tailor the properties and functions of these particles. The method generally involves the generation of an atmospheric plasma glow discharge and energetic species that undergo chemical reaction with the surface of the primary particles. The process includes the generation of energetic species to initiate reaction, optional delivery of a precursor fluid, optional delivery of chemical species for grafting, and delivery of separated and de-agglomerated particles into the plasma discharge exiting the plasma generation chamber.

Owner:KETTERING UNIVERSITY

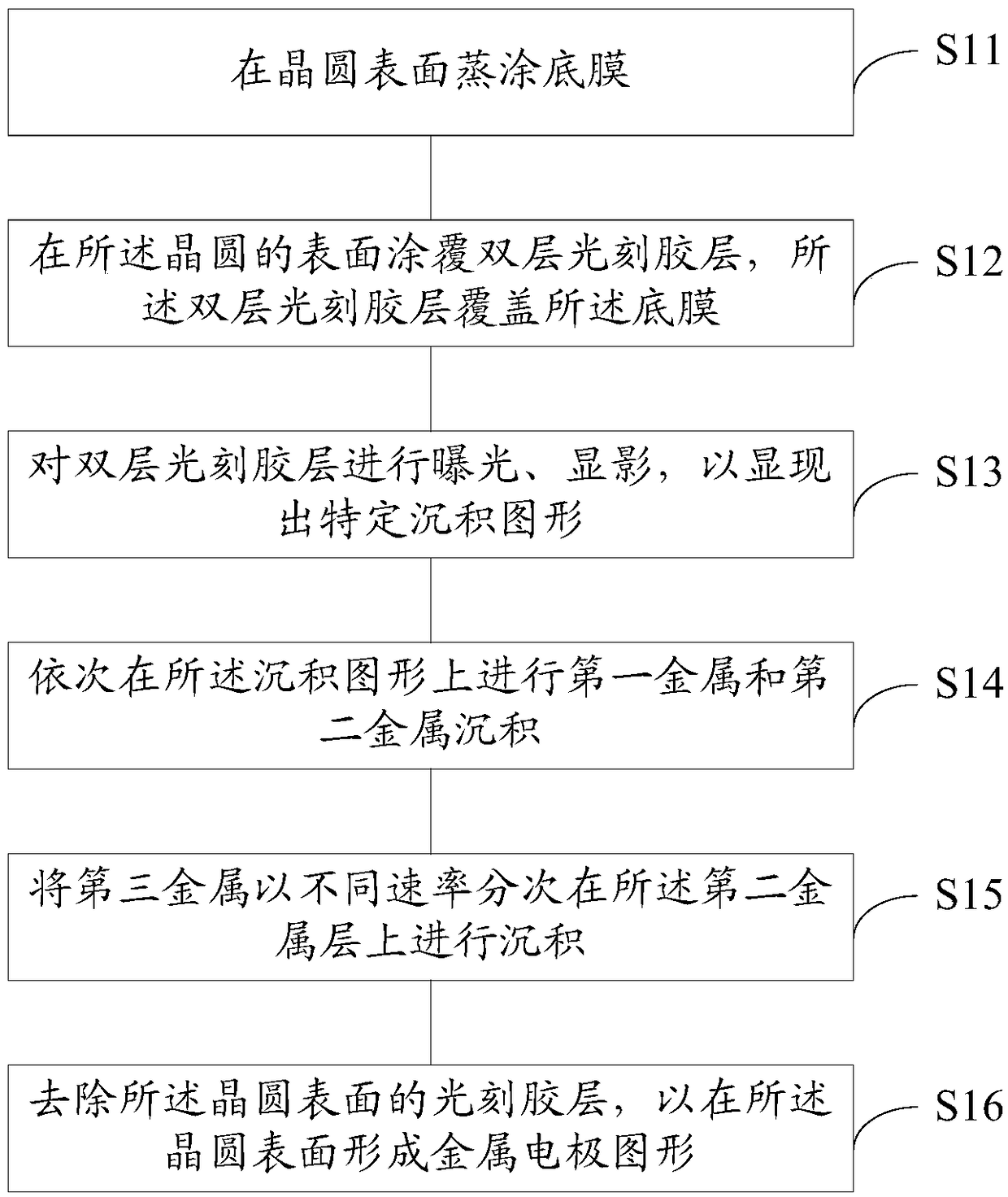

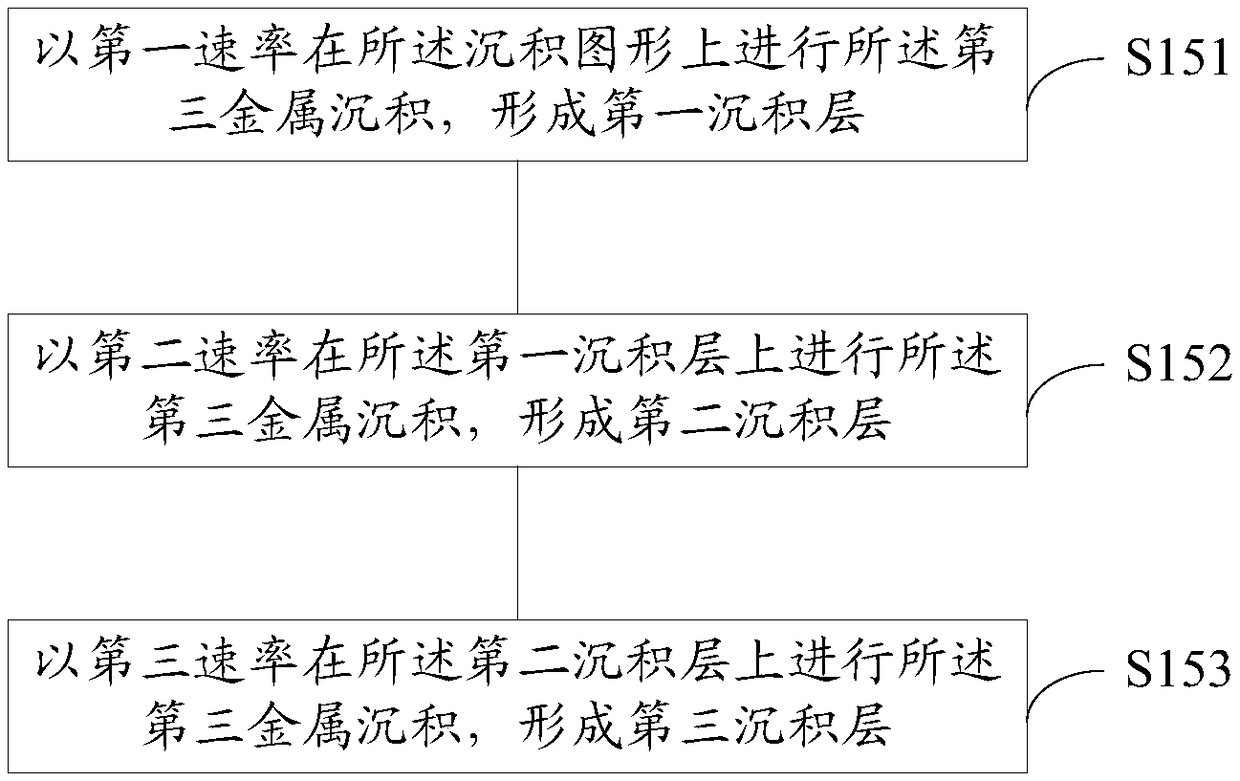

Method for depositing metal electrode

ActiveCN108899756AMaintain gel typeAvoid bombardmentLaser detailsSemiconductor lasersMetal stripsHigh energy

The invention discloses a method for depositing a metal electrode. The method comprises the steps of evaporating a bottom film on the surface of a wafer; coating a double-layer photoresist layer on the surface of the wafer, wherein the double-layer photoresist layer covers the bottom film; and performing exposure and development on the double-layer photoresist layer so as to display a specific deposition pattern; performing first metal deposition and second metal deposition on the deposition pattern in sequence; depositing third metal for multiple times on the second metal layer at different rates; and removing the photoresist layer on the surface of the wafer so as to form a metal electrode pattern on the surface of the wafer. The shape of the photoresist can be well maintained in a modeof matching the deposition with different deposition rates, thereby preventing a problem that the photoresist deforms and collapses under the bombardment of high-energy atoms for a long time, and solving a problem of difficult metal stripping.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

Forming method of interconnection structure

ActiveCN104299939AImproved anti-electromigration propertiesImprove interface stateSolid-state devicesSemiconductor/solid-state device manufacturingResistance capacitanceInterconnection

The invention discloses a forming method of an interconnection structure. The forming method comprises the following steps: providing a semiconductor substrate, wherein a dielectric layer is formed on the surface of the semiconductor substrate; forming an opening in the dielectric layer, wherein the bottom of the opening is exposed out of the surface of the semiconductor substrate; forming a metal layer filling the opening in the opening, wherein the surface of the metal layer is flush with the top of the dielectric layer; introducing methyl-containing germane gas into the surfaces of the metal layer and the dielectric layer, and performing germanium treatment on the surface of the metal layer to form a metal cap layer; and forming a dielectric cap layer on the surfaces of the metal cap layer and the dielectric layer. Through adoption of the forming method of the interconnection structure disclosed by the invention, damage to the dielectric layer of the interconnection structure can be effectively reduced while the electromigration resistance of the interconnection structure is enhanced; the RC (Resistance-Capacitance) delay of the interconnection structure is reduced; and the reliability of the interconnection structure is enhanced.

Owner:SEMICON MFG INT (SHANGHAI) CORP

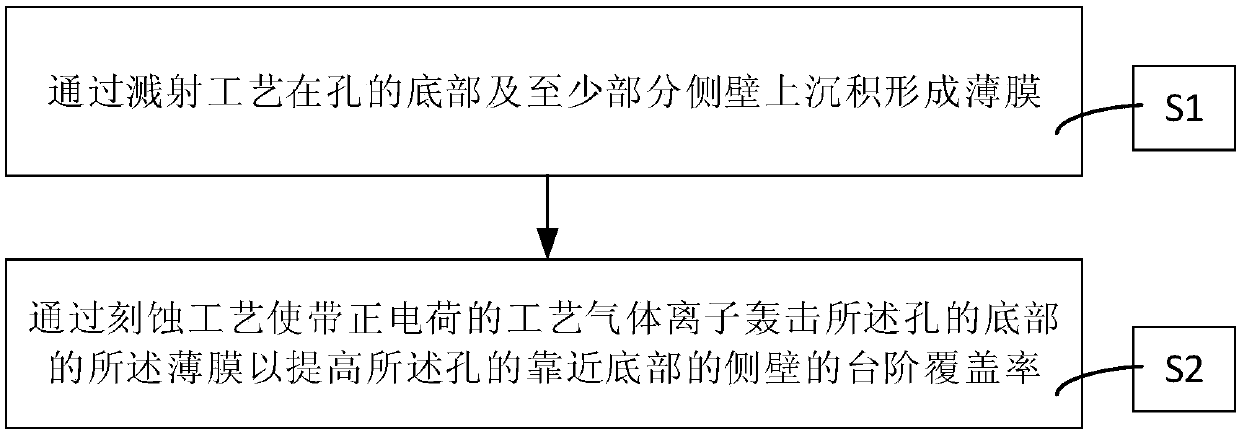

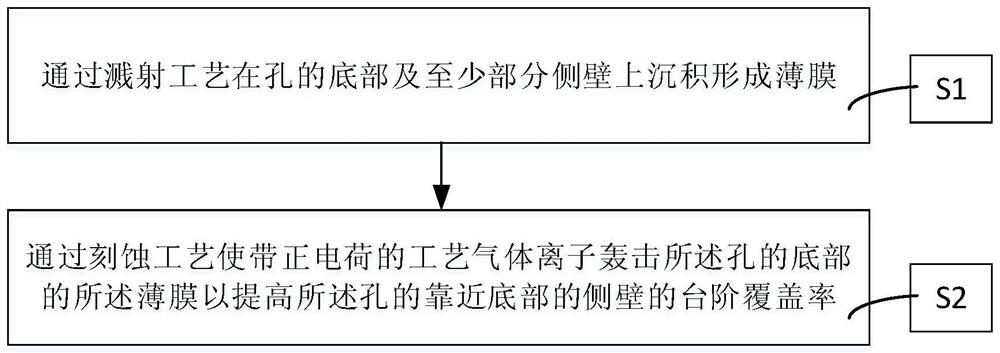

Method for covering thin film in hole and semiconductor processing apparatus

ActiveCN109887879AImprove deposition efficiencyLower the altitudeSemiconductor/solid-state device manufacturingSemiconductorIon

The present invention provides a method for covering a thin film in a hole and a semiconductor processing apparatus. The method of covering a thin film in the hole comprises the following steps: step1, depositing a thin film on the bottom of the hole and at least a part of the sidewall by a sputtering process; and step 2, bombarding the positively charged process gas ions on the thin film at thebottom of the hole by an etching process to improve the step coverage of the sidewall near the bottom of the hole. The method of covering the film in the hole can not only improve the process performance, but also give consideration to the production capacity of the apparatus.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

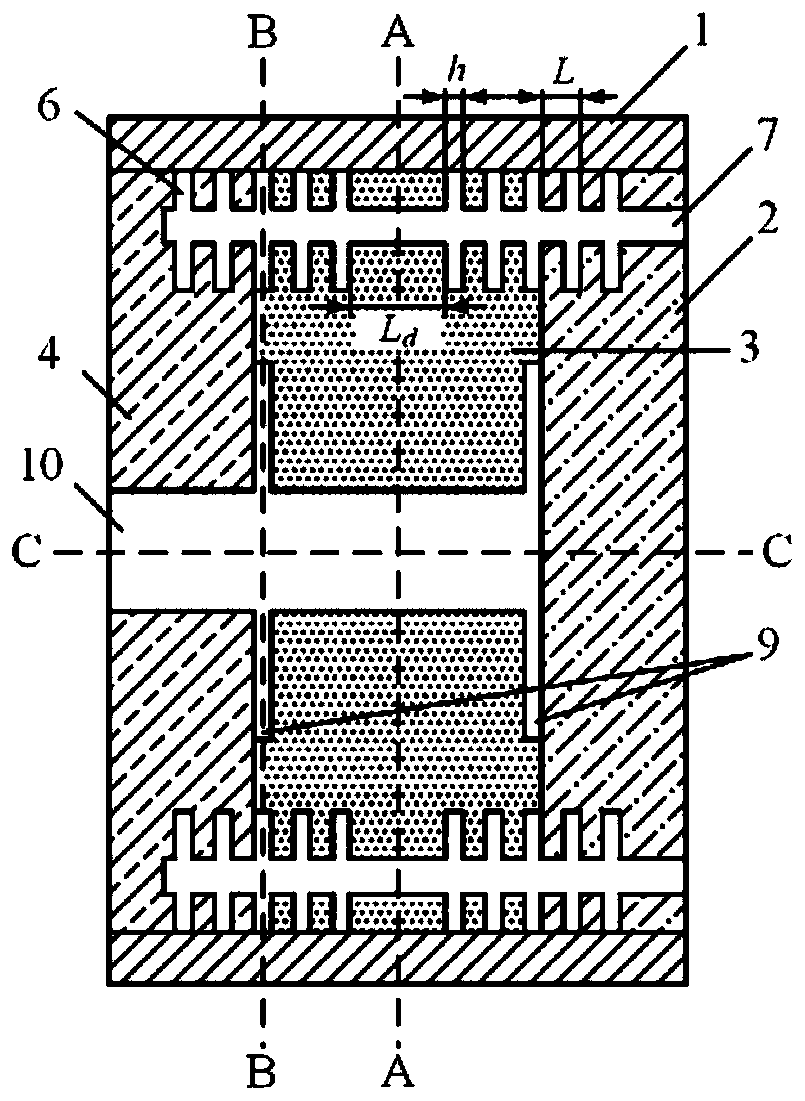

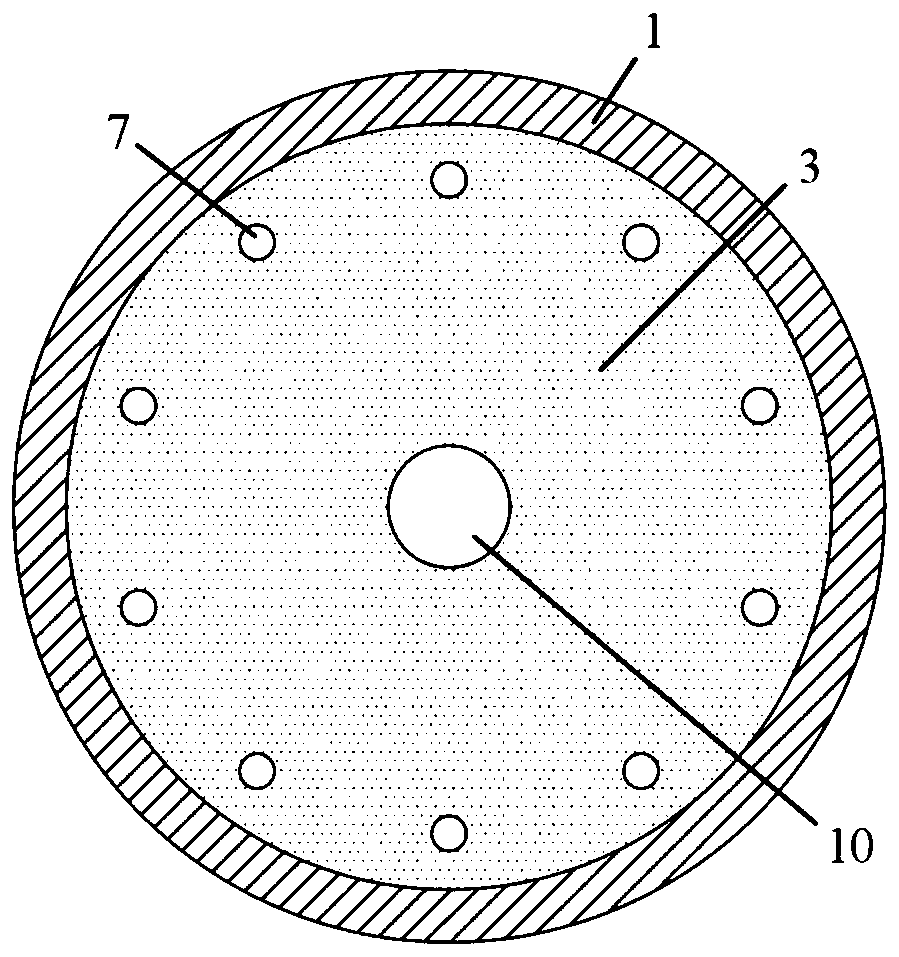

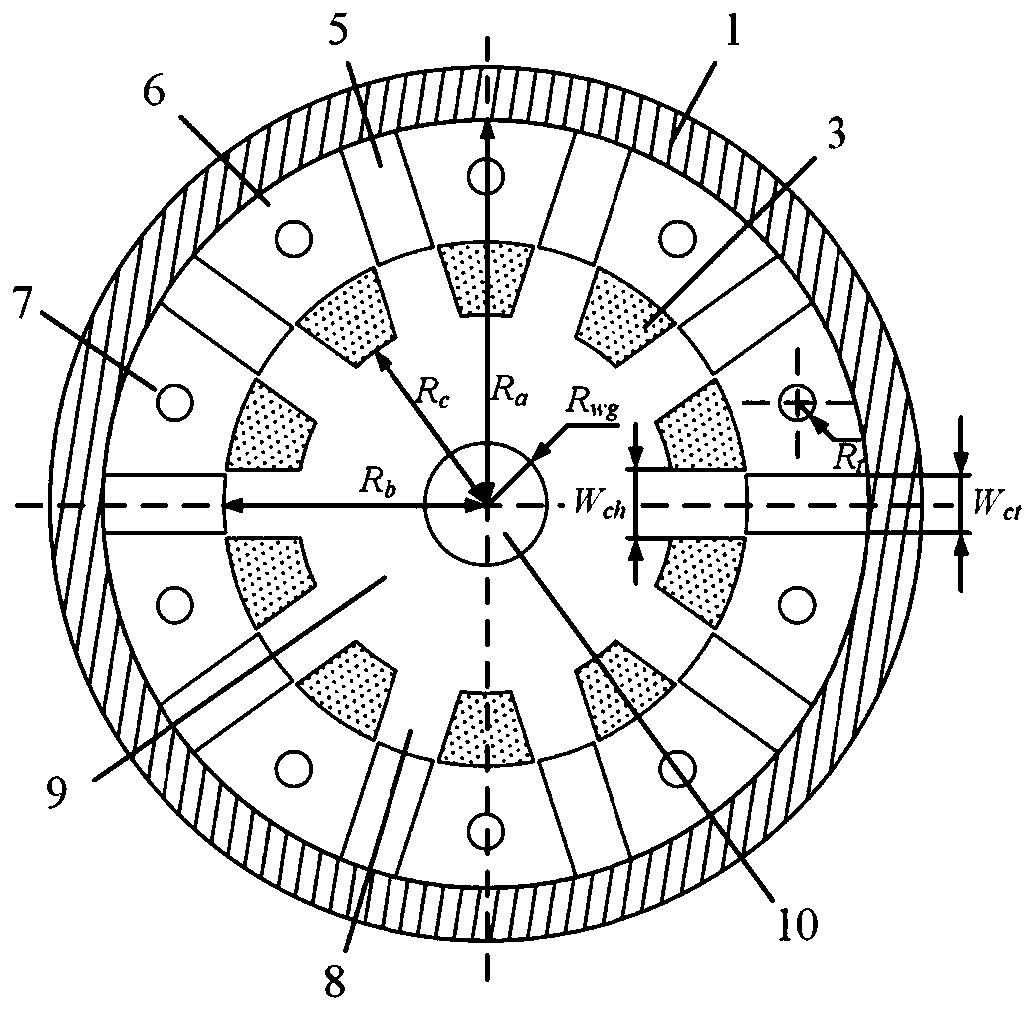

Multi-extraction type TM10,1,0 mode coaxial coupling cavity output circuit

The invention provides a multi-extraction type TM10,1,0 mode coaxial coupling cavity output circuit. The energy of electron beams is extracted through a plurality of separated and coupled TM10,1,0 mode coaxial coupling cavities, after the energy is converted into electromagnetic waves, the electromagnetic waves are coupled into an output circular waveguide in the axial direction through rectangular coupling holes and a mode conversion cavity, and the same-phase superposition of output electromagnetic waves is realized by adjusting the distance between the coaxial coupling cavities and the waveguide wavelength of the output circular waveguide. Each of the coaxial coupling cavities comprises several coaxial resonant cavities working in the TM10,1,0 mode, 10 electron beam channels for workingfrequency band electromagnetic wave cutoff are placed, each of the electron beam channels can allow one or more electrons to pass, that is at least 10 electron beams can be received, therefore, the power and efficiency of a device are improved, and the current density of the electron beams is reduced.

Owner:GUANGDONG UNIV OF TECH

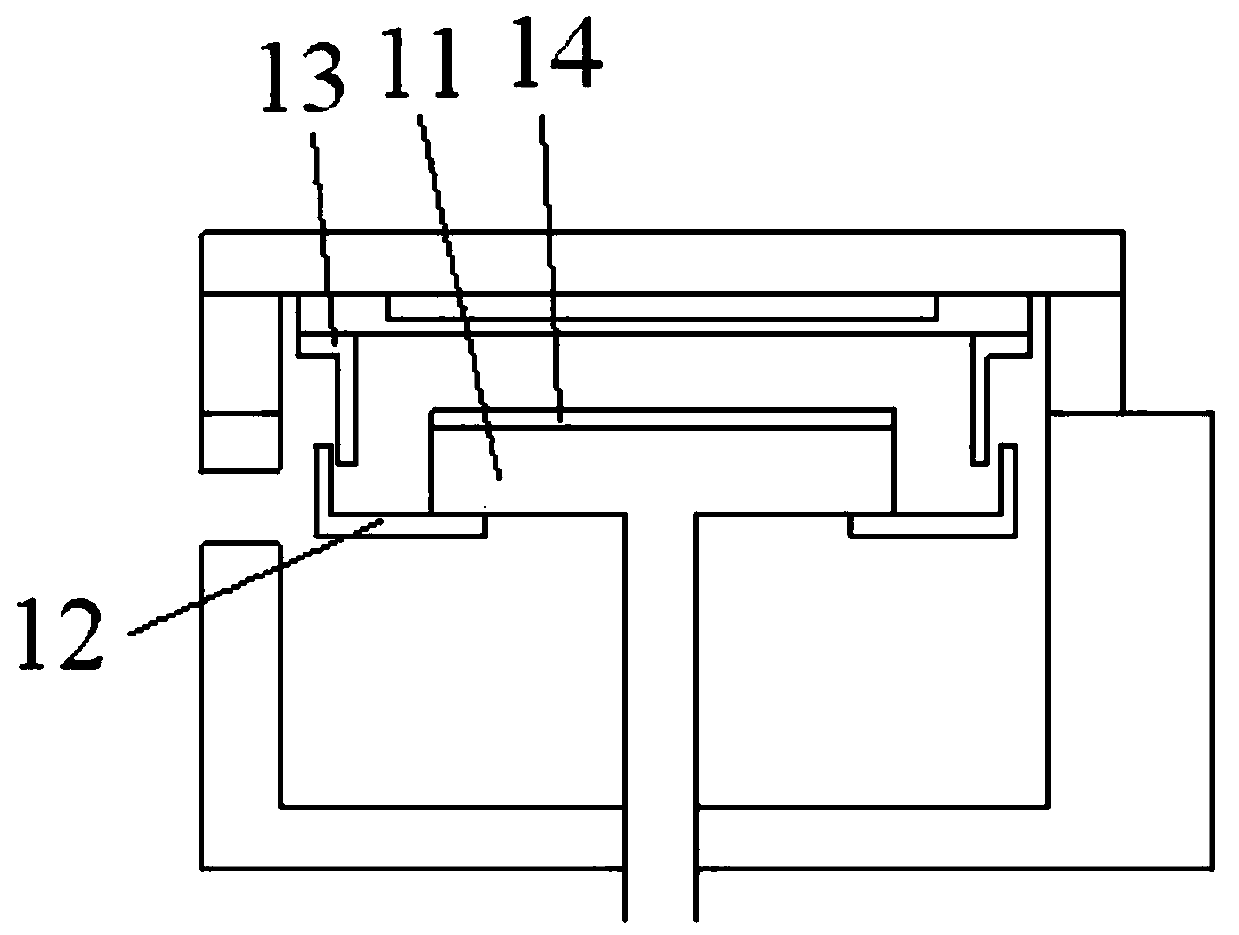

High-working-ratio nano material cold cathode electron gun

InactiveCN109637919ASimple structureEasy to assembleMaterial nanotechnologyElectrode and associated part arrangementsElectricitySemiconductor materials

The invention relates to a high-working-ratio nano material cold cathode electron gun, which comprises a focusing electrode, an anode, a cathode, a shadow grid and a control grid, the shadow grid is arranged on a cold cathode emission surface, the shadow grid and the cold cathode emission surface are in an equipotential state, and the shadow grid is prepared from a metal material or a semiconductor material; and the control grid is arranged right in front of the shadow grid at a preset distance, the shape of the control grid is similar to that of the shadow grid, and the shadow grid and the control grid are arranged opposite to each other and are arranged opposite to the cathode emission surface. According to the cold cathode electron gun adopting the technical scheme, electron bombardmentof the control grid is avoided, the problem that the control grid is burnt is solved, the problem that the cold cathode electron gun only can work in a small working ratio state is solved, the application of a nano material cold cathode electron gun in an electric vacuum device is expanded, and even development of rapid starting of an electronic system is promoted The cold cathode electron gun has the characteristics of simple structure and convenience in assembly.

Owner:中山科立特光电科技有限公司

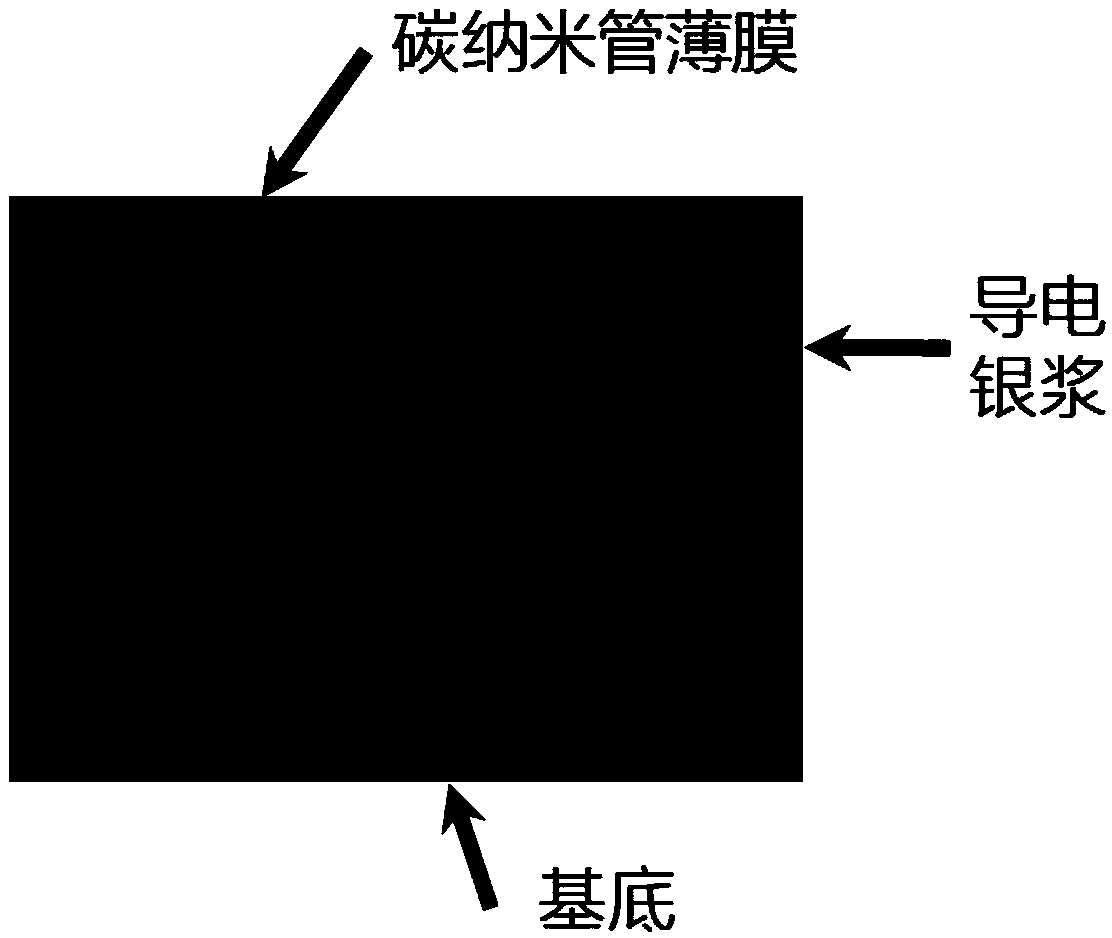

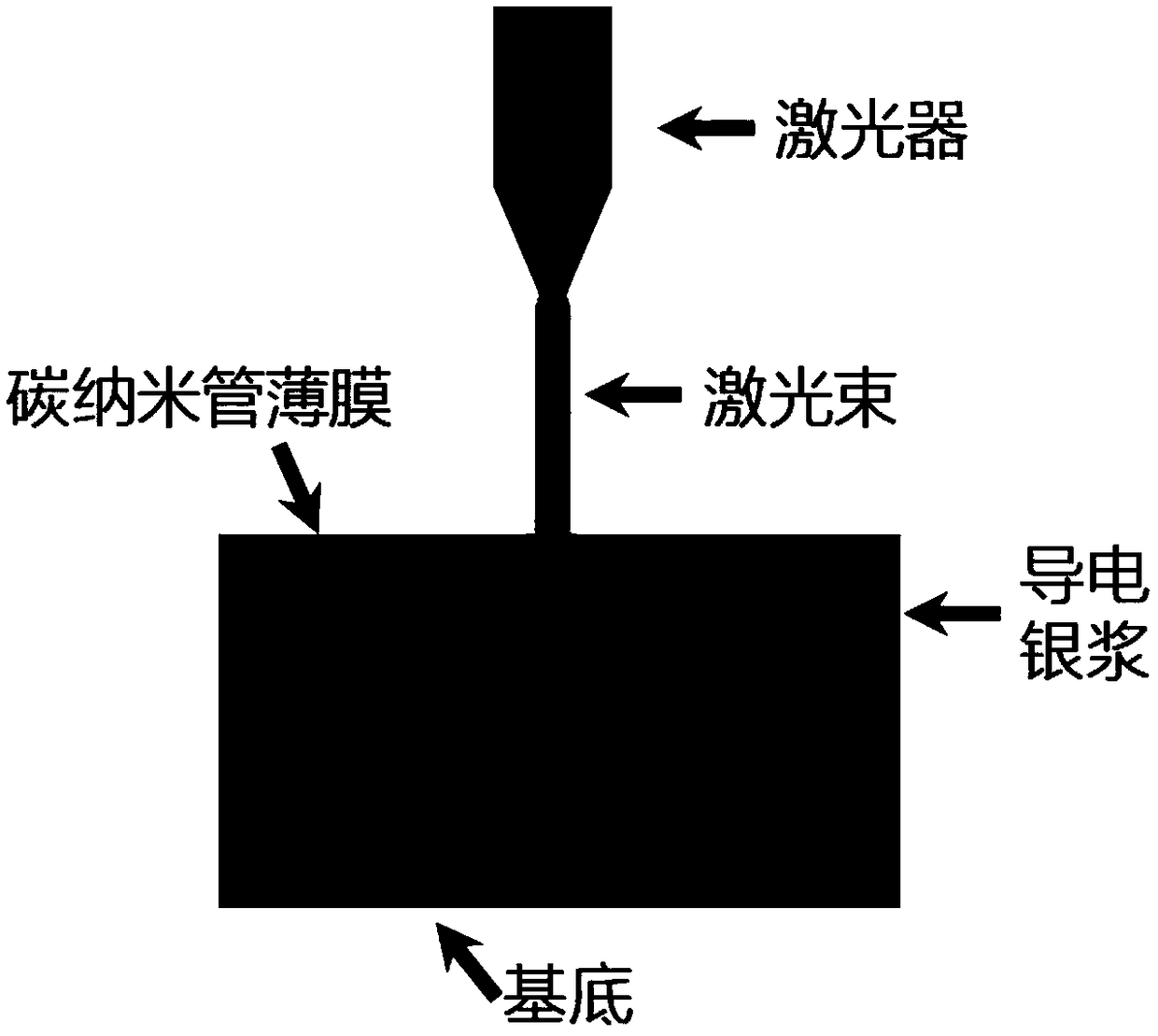

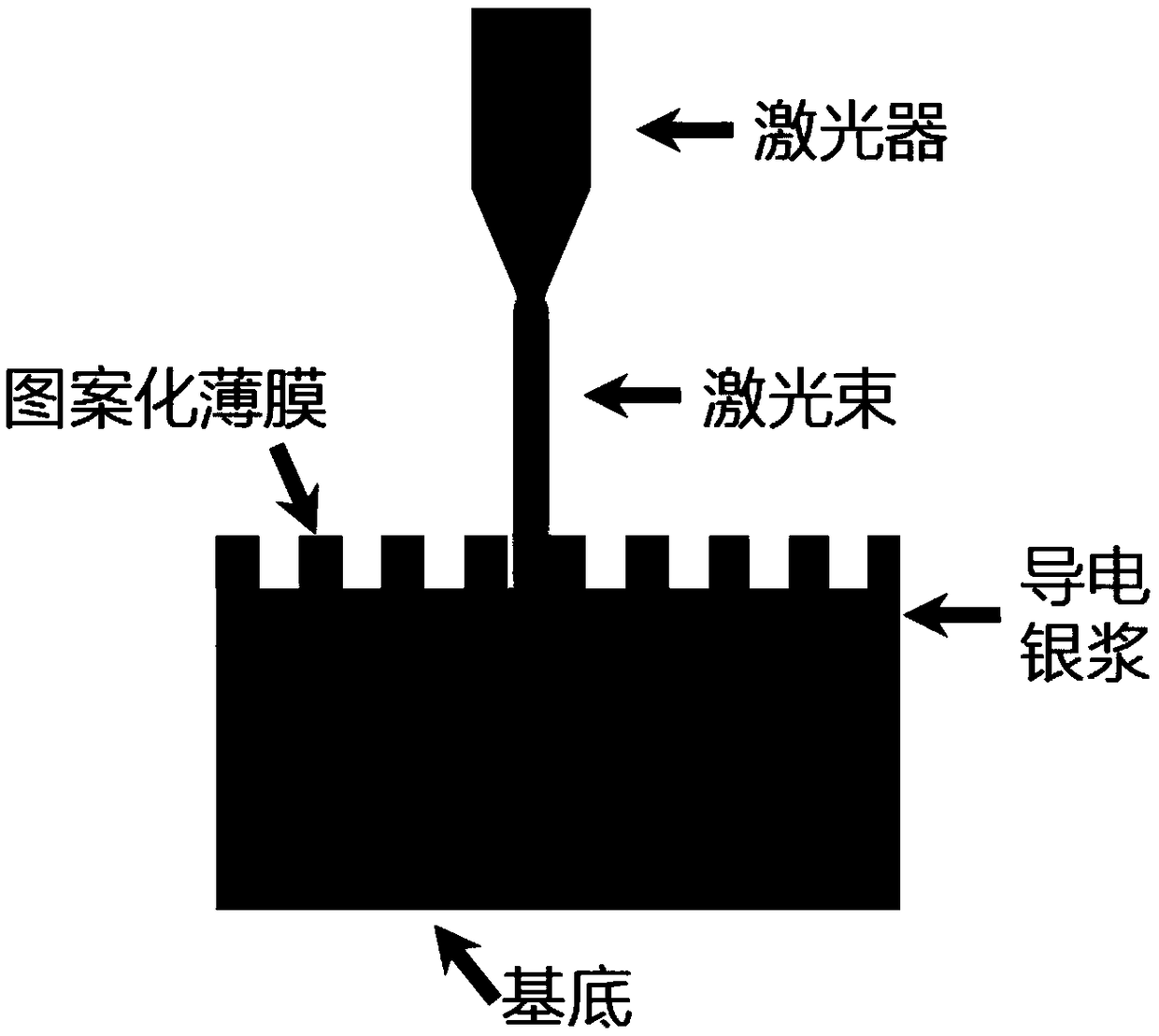

Patterned preparation method of nano material field emission cathode

InactiveCN108933068AReduce interceptionReduce feverCold cathode manufactureMaterials preparationLaser processing

The invention discloses a patterned preparation method of a nano field emission cold cathode, belongs to the field of material preparation, and particularly relates to the preparation of a nano material clod cathode such as carbon nanotubes, graphene and zinc oxide applied to a field emission electron gun of vacuum electronic devices. In allusion to drawbacks existing in the background technology,the invention designs a patterned preparation method of a nano material field emission cathode by combining a laser processing technology. The patterned field emission cathode can greatly improve theperformance of an electron gun based on the nano material clod cathode and has important practical application significance for improving the stability of cold cathode devices.

Owner:SOUTHEAST UNIV

Reaction chamber and semiconductor processing equipment

PendingCN110828271AAvoid bombardmentTo preventElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention provides a reaction chamber and semiconductor processing equipment, and the reaction chamber comprises a substrate, a tray borne on the substrate, a cover plate and a lining. The tray comprises a bearing position for bearing the substrate, and the cover plate is used for covering the area, except the bearing position, of the tray. The lining is arranged around the inner side of the side wall of the reaction chamber, a supporting part is arranged on the lining, and the supporting part is used for supporting the cover plate to separate the cover plate from the tray when the substrate descends from the process position. According to the reaction chamber provided by the invention, ions generated by process gas can be prevented from bombarding the tray, and pollutants are prevented from being generated, so that the etching rate and uniformity of pre-cleaning are improved, and the process capacity and process effect are improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

System for preparing ITO thin films by adopting magnetron sputtering and capable of enhancing film forming quality

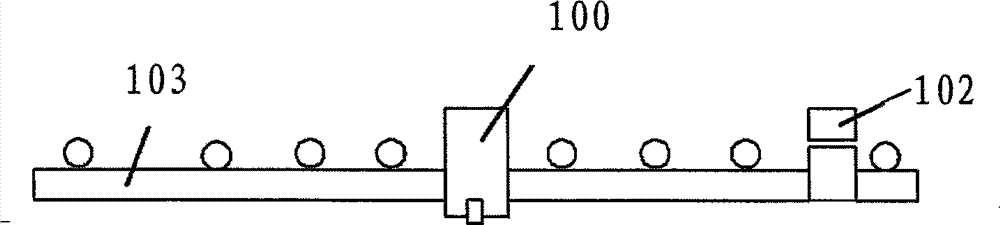

ActiveCN107142452AHigh film forming efficiencyImprove productivityVacuum evaporation coatingSputtering coatingProduction lineCooling chamber

The invention discloses a system for preparing ITO thin films by adopting magnetron sputtering and capable of enhancing film forming quality. The system comprises a preheating chamber, a depositing chamber, a cooling chamber, a finished-product chamber, a vacuum pump and a control panel, wherein the preheating chamber, the depositing chamber, the cooling chamber, the finished-product chamber and the vacuum pump are connected in sequence. ITO target materials and magnets are arranged on the two side walls of the depositing chamber, and baffles capable of being opened and closed are arranged at the front ends of the ITO target materials; air vents are evenly formed in the two side walls of the depositing chamber, and moreover, the air vents of the two side walls are formed in a staggered mode to lead reaction gases into the depositing chamber; a second heating plate is arranged on the bottom surface of the cooling chamber; and a plurality of grilles are arranged in the finished-product chamber to separate the finished-product chamber into multiple separated chambers evenly. According to the system for preparing the ITO thin films by adopting magnetron sputtering and capable of enhancing the film forming quality, the production line type preparing system is adopted, so that the film forming efficiency is enhanced greatly, and the film forming is even and high in quality; and meanwhile, the system controls the steps of film forming and cooling, and further the film forming quality is enhanced.

Owner:LIUZHOU HAOXIANGTE SCI & TECH

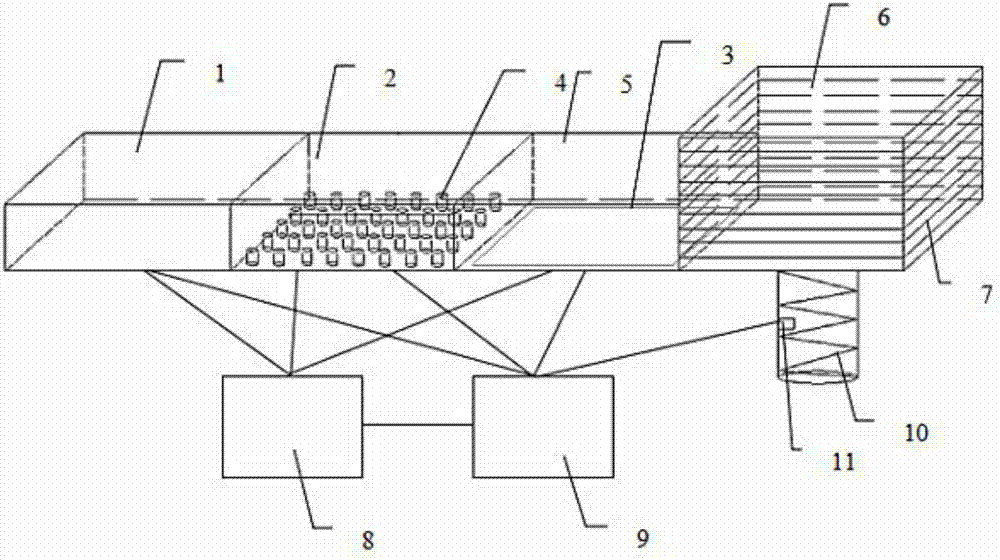

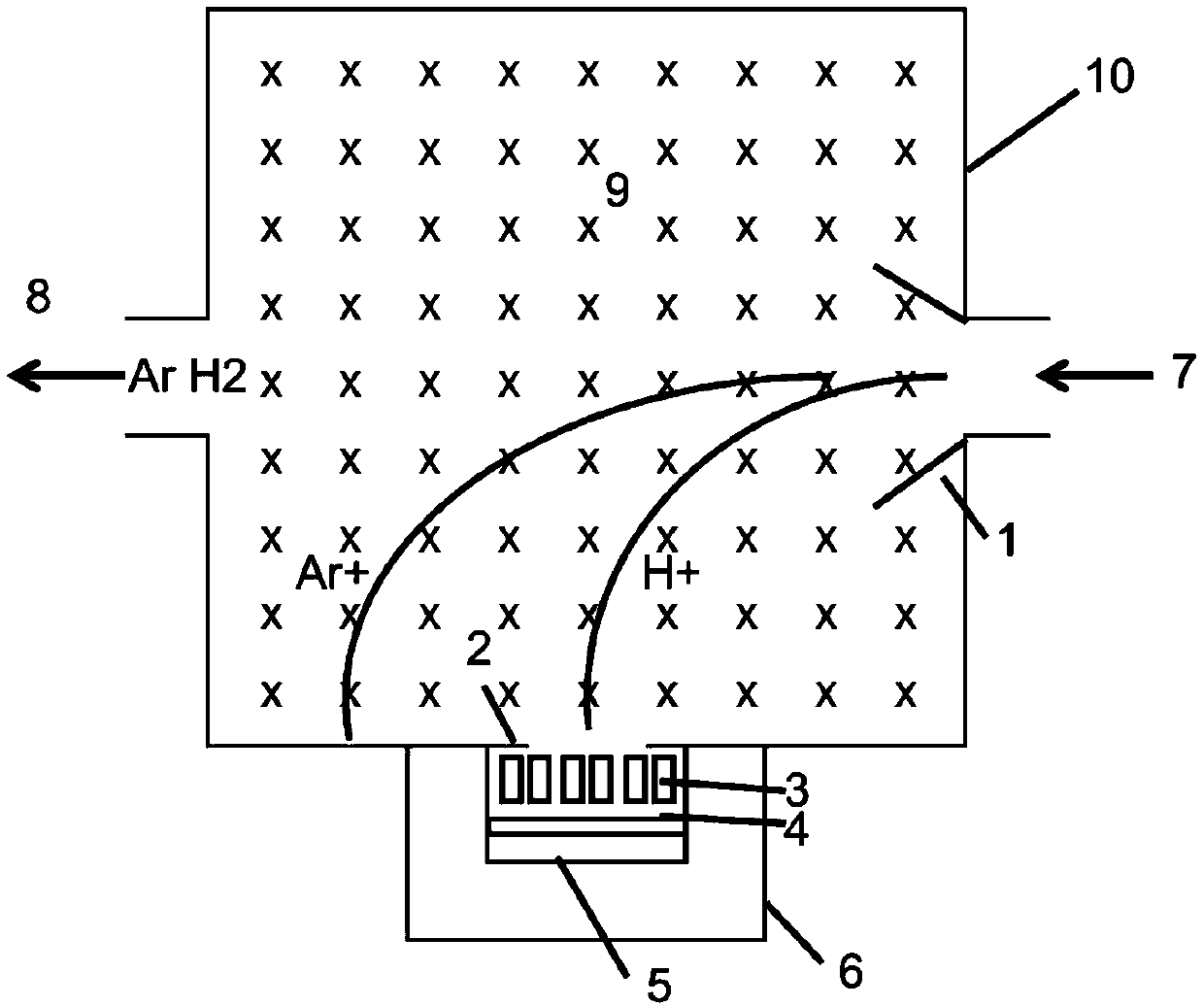

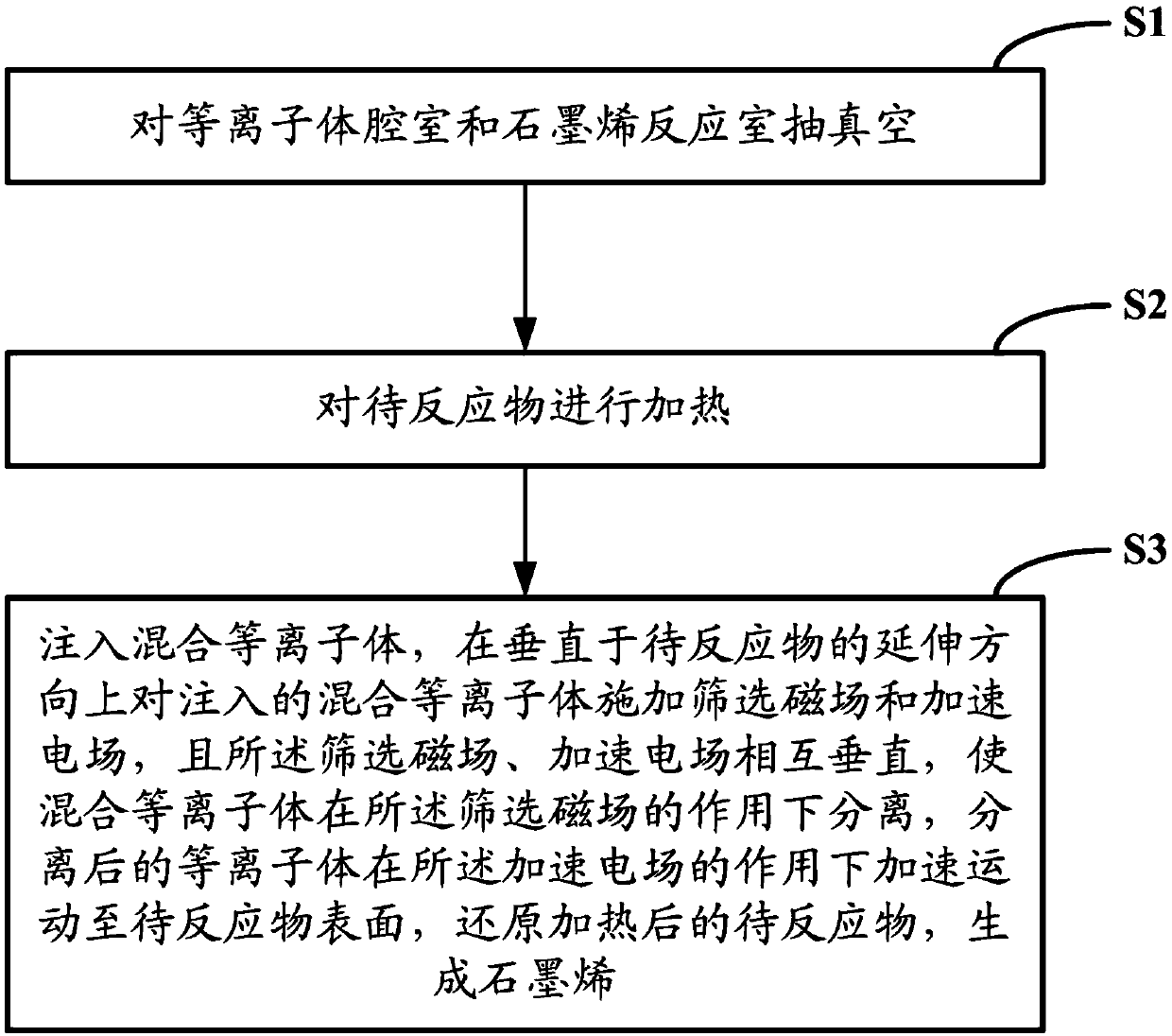

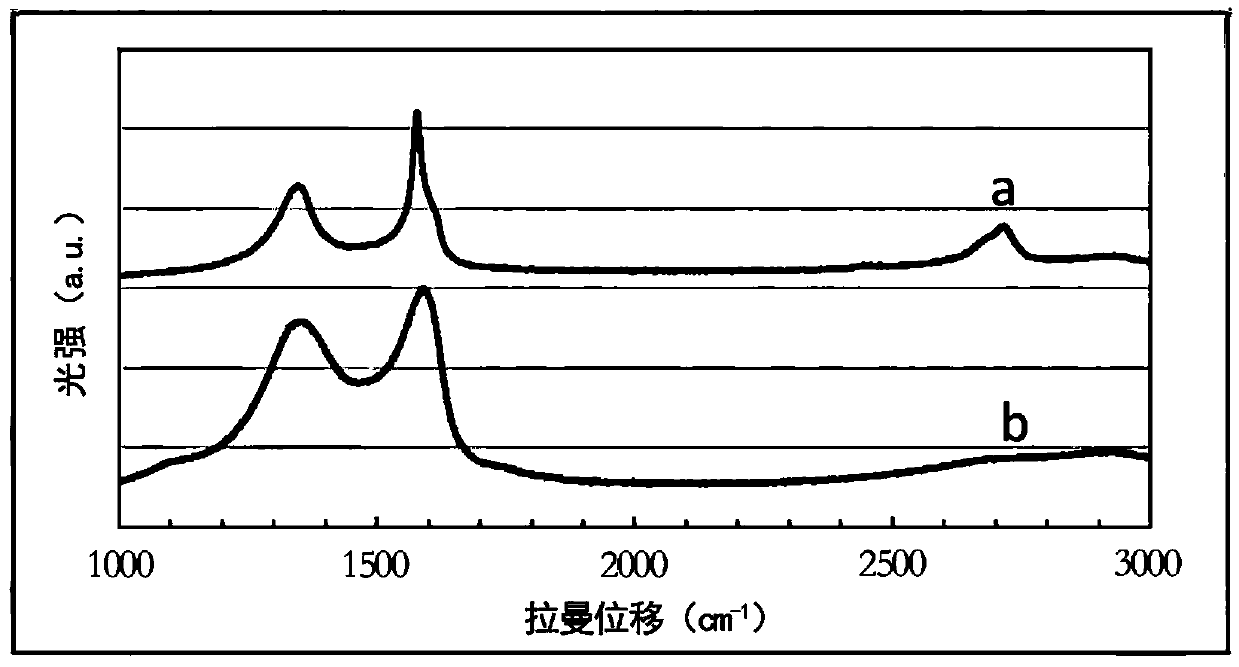

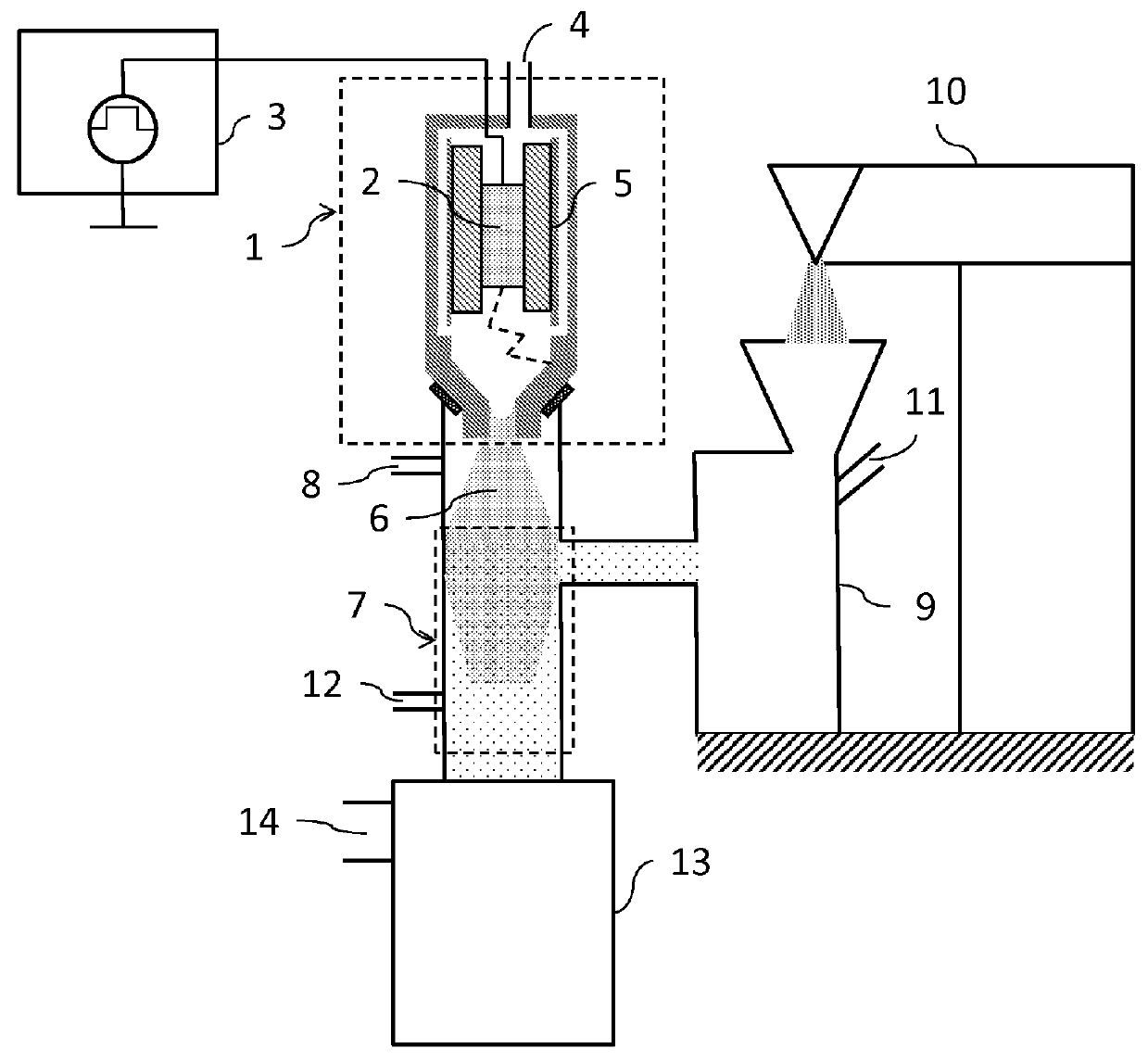

Preparation apparatus and preparation method of graphene

The invention relates to the technical field of graphene preparation and especially relates to a preparation apparatus and a preparation method of graphene. The preparation apparatus includes: a graphene reaction chamber, in which a heating plate for supporting a reactant is arranged; and a plasma chamber communicated with the graphene reaction chamber and arranged at one side of same, wherein a plasma jet orifice is arranged on one end of the plasma chamber and is used for injecting mixed plasma, the injection direction of the mixed plasma is same as the extension direction of the reactant; amagnetic field generation apparatus is disposed in the plasma chamber; an electric field generation apparatus is arranged in the graphene reaction chamber; the direction of the accelerating electricfield generated by the electric field generation apparatus, the direction of screening magnetic field generated by the magnetic field generation apparatus, and the extension direction of the reactantare vertical in pairs. In the apparatus, the screening magnetic field is used for screening argon ion and hydrogen ion, so that bombarding and etching effect due to the argon ion on graphene oxide canbe avoided.

Owner:ENN SCI & TECH DEV

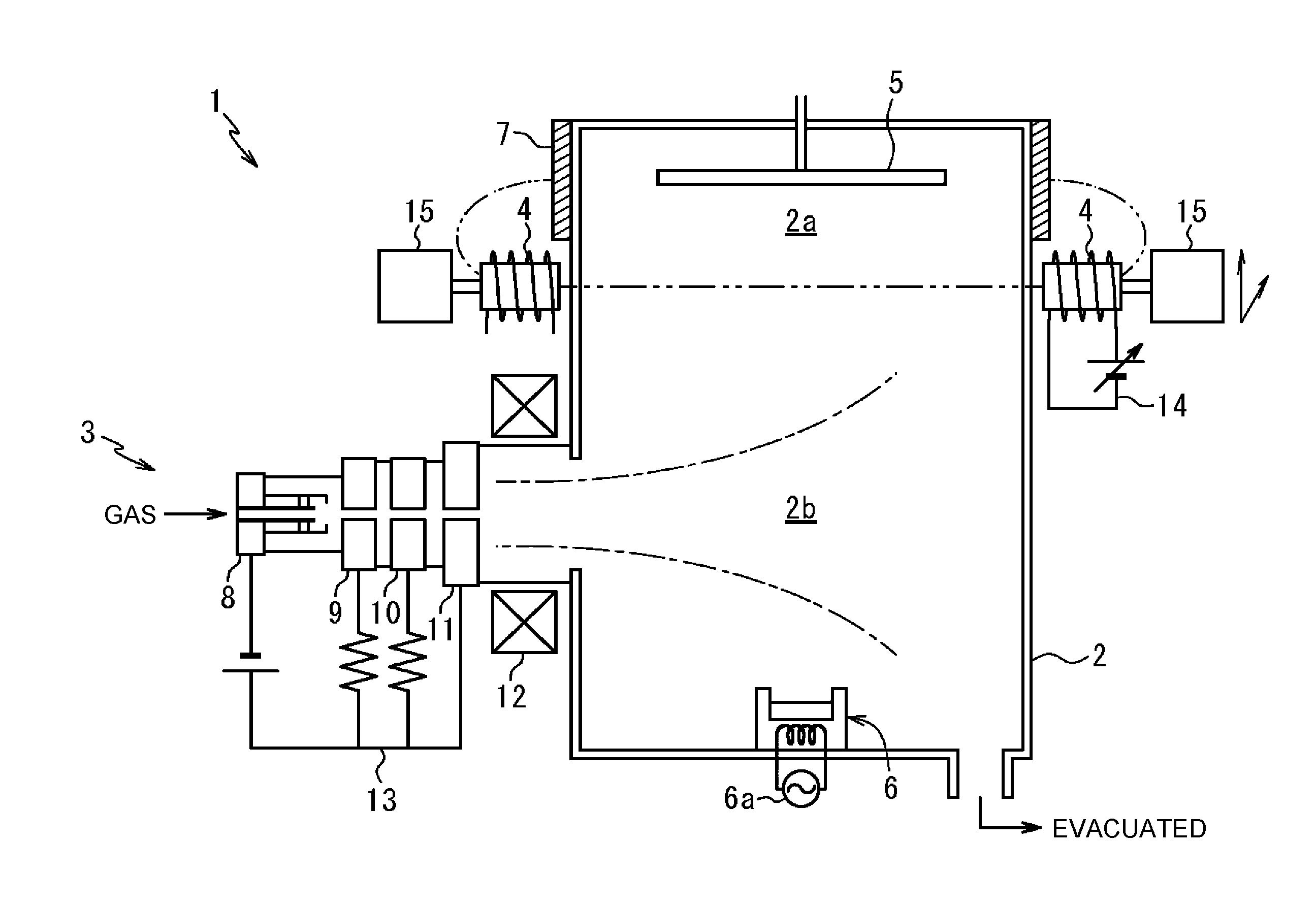

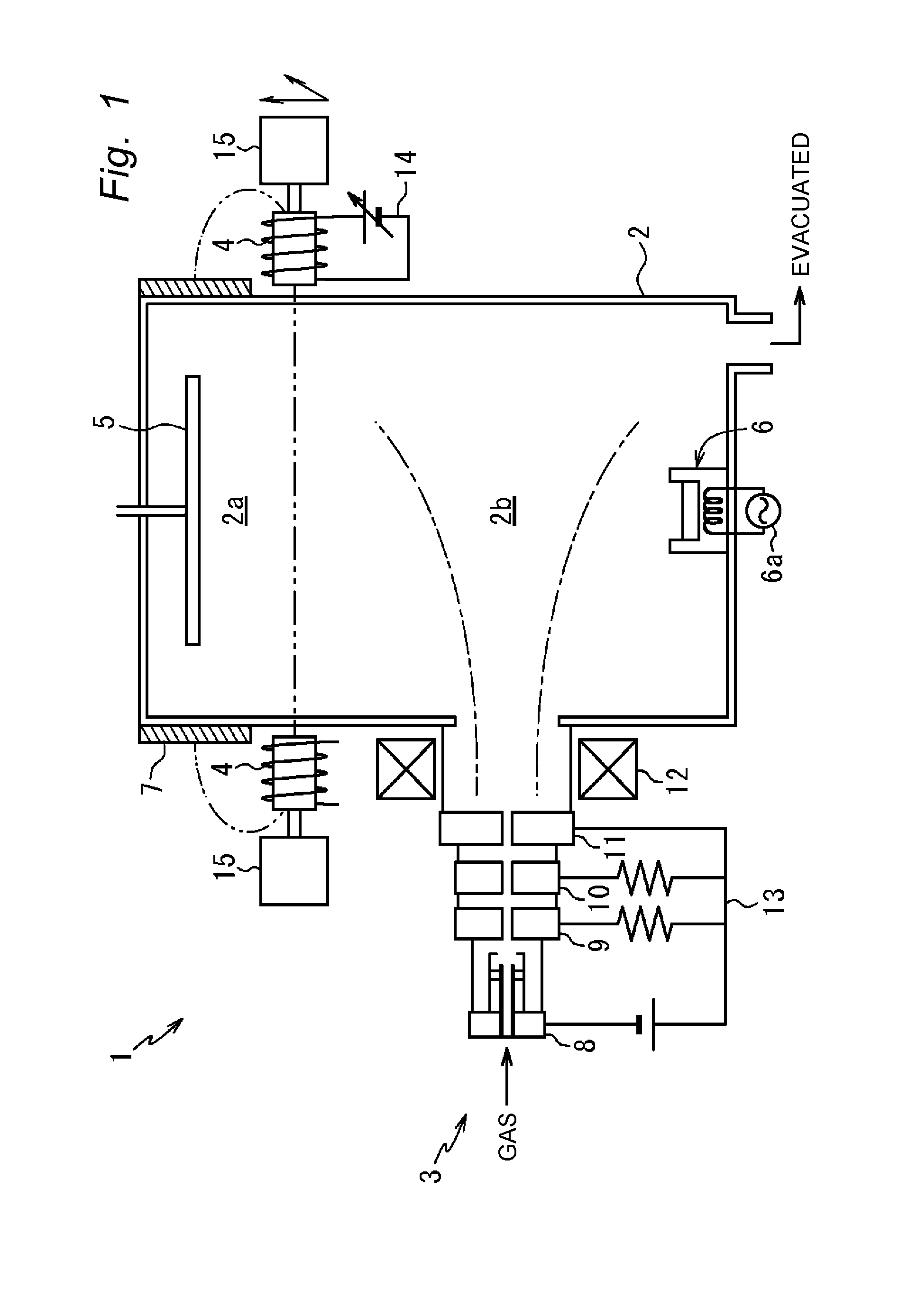

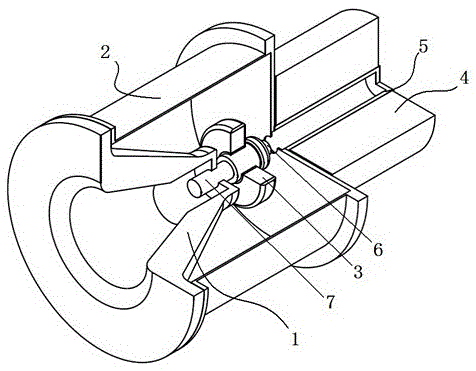

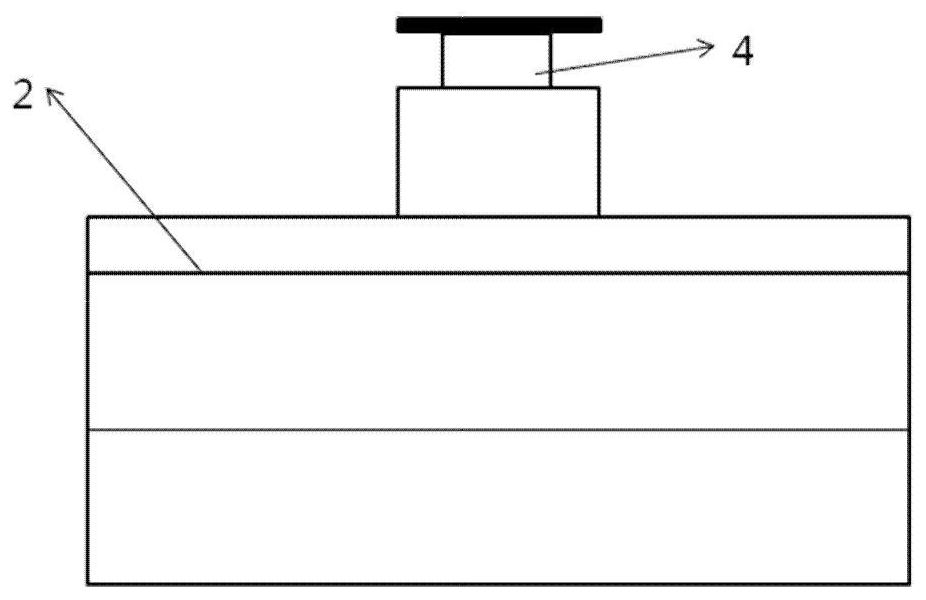

Plasma processing apparatus

InactiveUS20140238301A1Limited amountAvoid bombardmentElectric discharge tubesVacuum evaporation coatingMagnetic fluxElectron

The present invention provides a plasma processing apparatus capable of bringing plasma close to a processing target and separating the plasma from the processing target. The plasma processing apparatus 1 according to the present invention has a chamber internally having a holding space 2a in which a processing target object 5 is held, and a plasma space 2b in which plasma is to be formed, a plasma gun 3 for emitting electrons into the plasma space 2b to form the plasma, and at least one pair of position-adjustable opposed magnets 4 for forming a magnetic flux passing across the chamber 2, between the holding space 2a and the plasma space 2b.

Owner:CHUGAI RO CO LTD

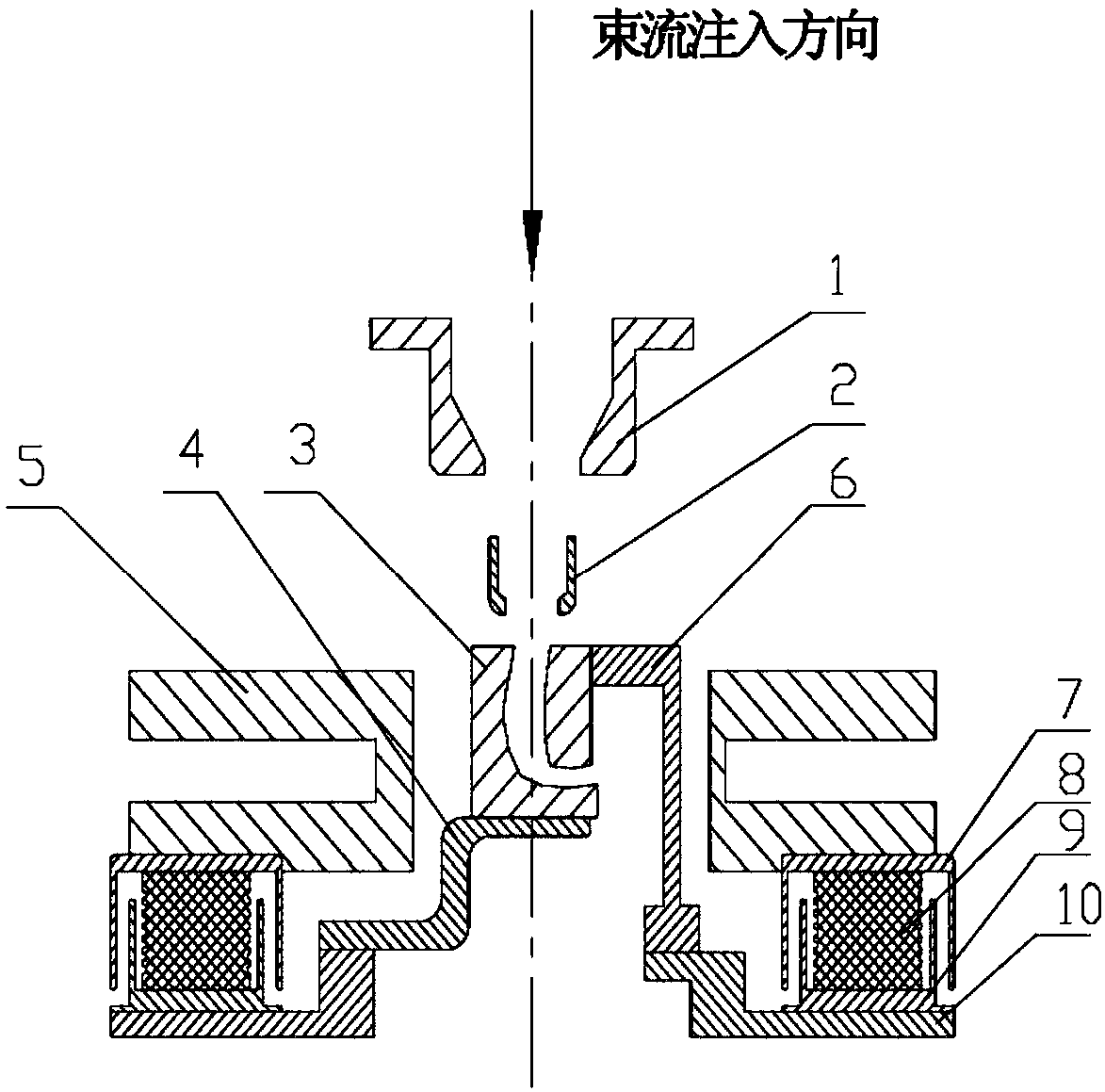

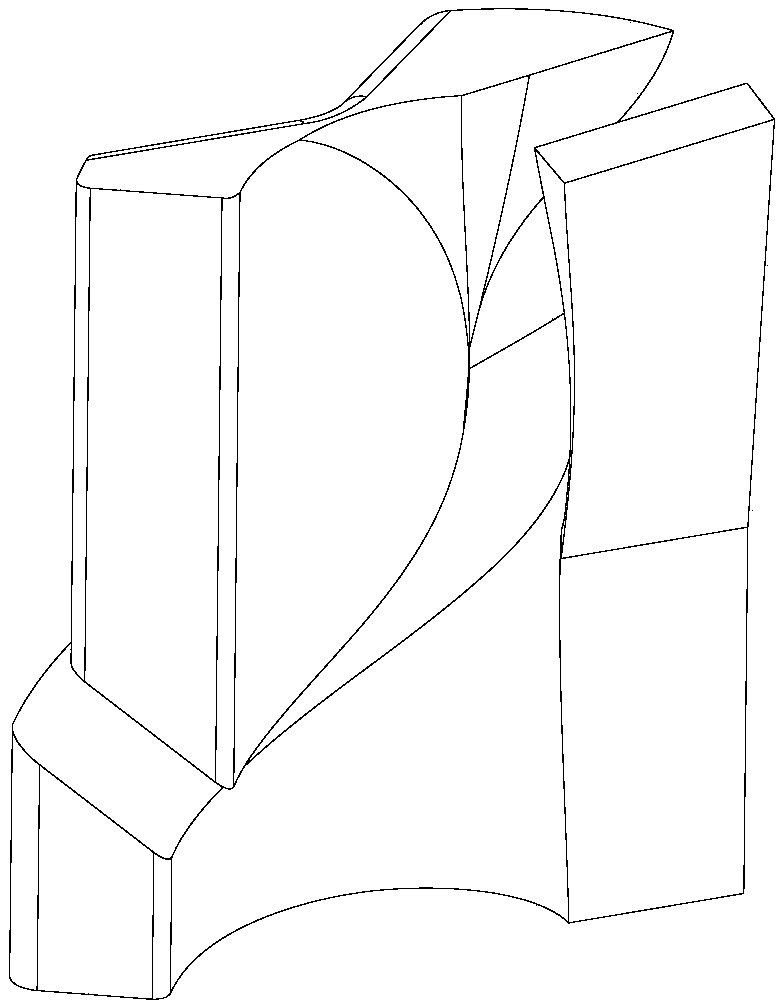

A Cyclotron Injection Beam Deflection Plate and Central Area Device

ActiveCN106132068BHigh output beam intensityStable jobMagnetic resonance acceleratorsEngineeringHigh pressure

The invention belongs to a cyclotron design technology, and specifically relates to a cyclotron injected beam current deflection plate and center device. The device comprises a center flange plate, a spiral deflection plate is arranged in the middle of the center flange plate, the spiral deflection plate and a supporting component thereof are fixed on the center flange plate via high-voltage insulated ceramic posts, a beam current diaphragm for preventing stray beam current from bombarding the spiral deflection plate is arranged above the spiral deflection plate, and a high-voltage insulated protective cover is arranged outside each high-voltage insulated ceramic post. The device has the advantages that vertically injected beam current can deflect to a horizontal acceleration track via the spiral deflection plate, and the stray beam current is prevented from bombarding the deflection plate via the protection of the secondary beam current diaphragm, so that the center works stably.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

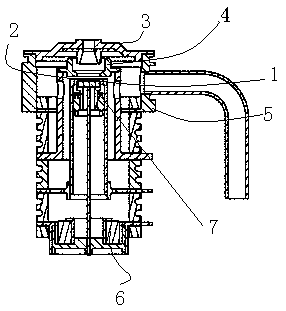

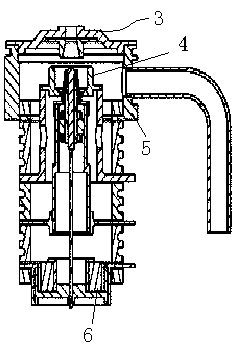

Method and apparatus for surface chemical functionalization of powders and nanoparticles

A method and apparatus is provided for the modification of the surface chemistry of solid nano- and micro-particles in order to tailor the properties and functions of these particles. The method generally involves the generation of an atmospheric plasma glow discharge and energetic species that undergo chemical reaction with the surface of the primary particles. The process includes the generation of energetic species to initiate reaction, optional delivery of a precursor fluid, optional delivery of chemical species for grafting, and delivery of separated and de-agglomerated particles into the plasma discharge exiting the plasma generation chamber.

Owner:KETTERING UNIVERSITY

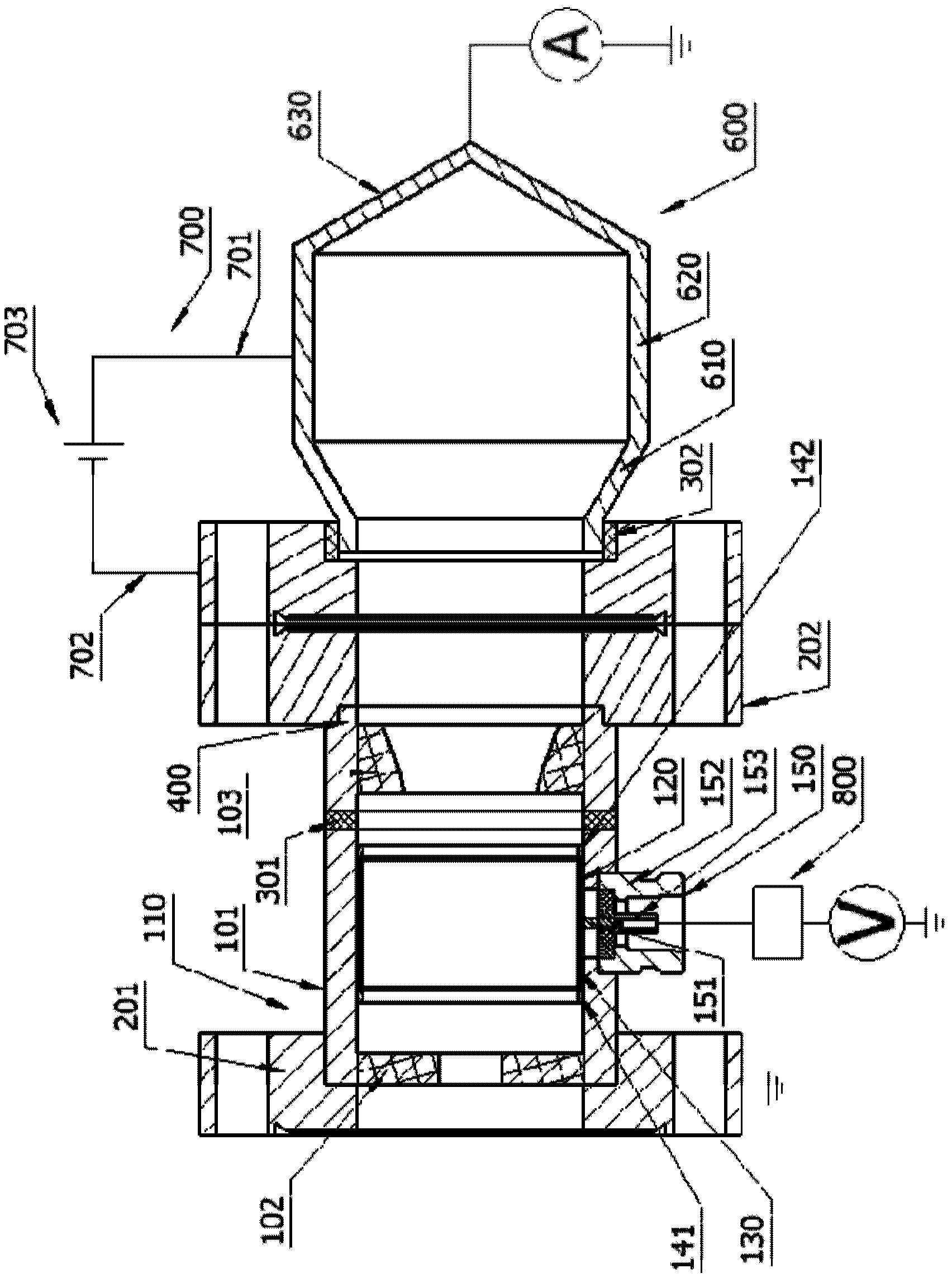

An Axial Foilless Diode Composite Guided Magnetic Field System

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

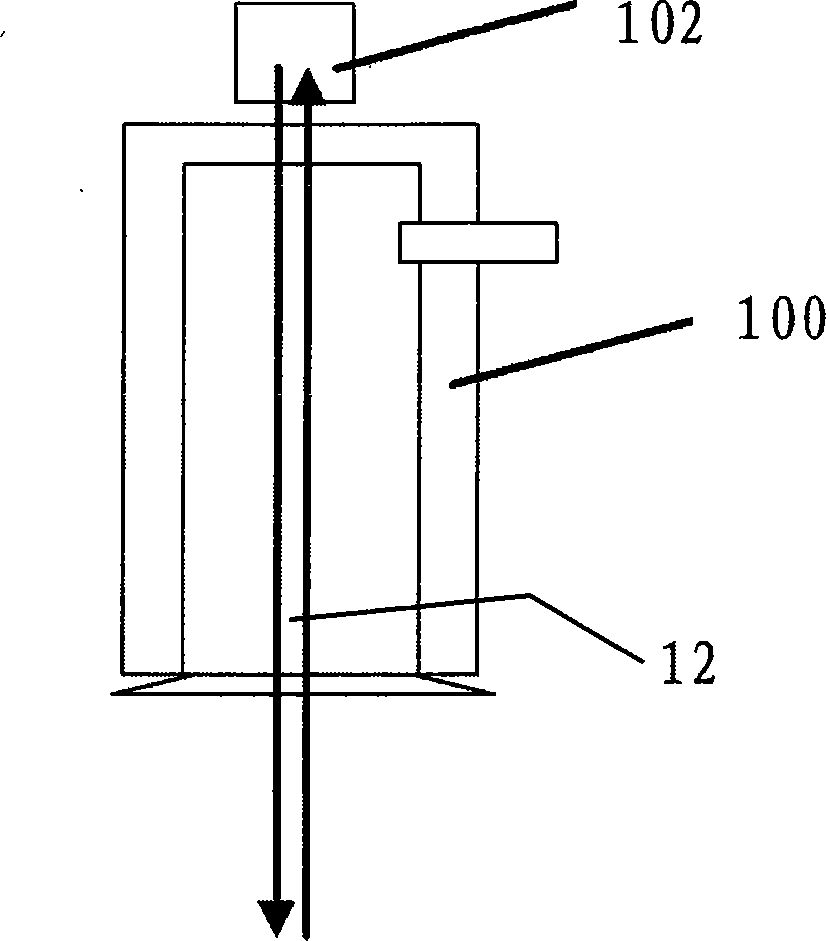

Capacitive probe device with function of reducing electric field distortion

InactiveCN103808990AReduce electric field distortion functionReduce electric field distortionElectrical measurement instrument detailsElectrical testingMetallic materialsElectric field distortion

The invention provides a capacitive probe device with the function of reducing electric field distortion. The capacitive probe device comprises a cylindrical vacuum cavity structure, an insulating ceramic barrel fixed to the inner side of the vacuum cavity structure, an annular electron beam induction ring which is made of a metal conducting material and is fixed to the middle of the inner side of the insulating ceramic barrel, annular electric field improving rings which are made of a metal conducting material, fixed to the upper portion and the lower portion of the inner side of the insulating ceramic barrel, insulated from the electron beam induction ring, and equipotential with the vacuum cavity structure, and a lead adapting assembly which is used for leading an induction signal of the electron beam induction ring out of the vacuum cavity structure. In the capacitive probe device, the electric field improving rings which are insulated from the electron beam induction ring are arranged on both sides of the electron beam induction ring, thereby greatly reducing the electric field distortion on the edges of both sides of the electron beam induction ring, and making an electron field more uniform.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

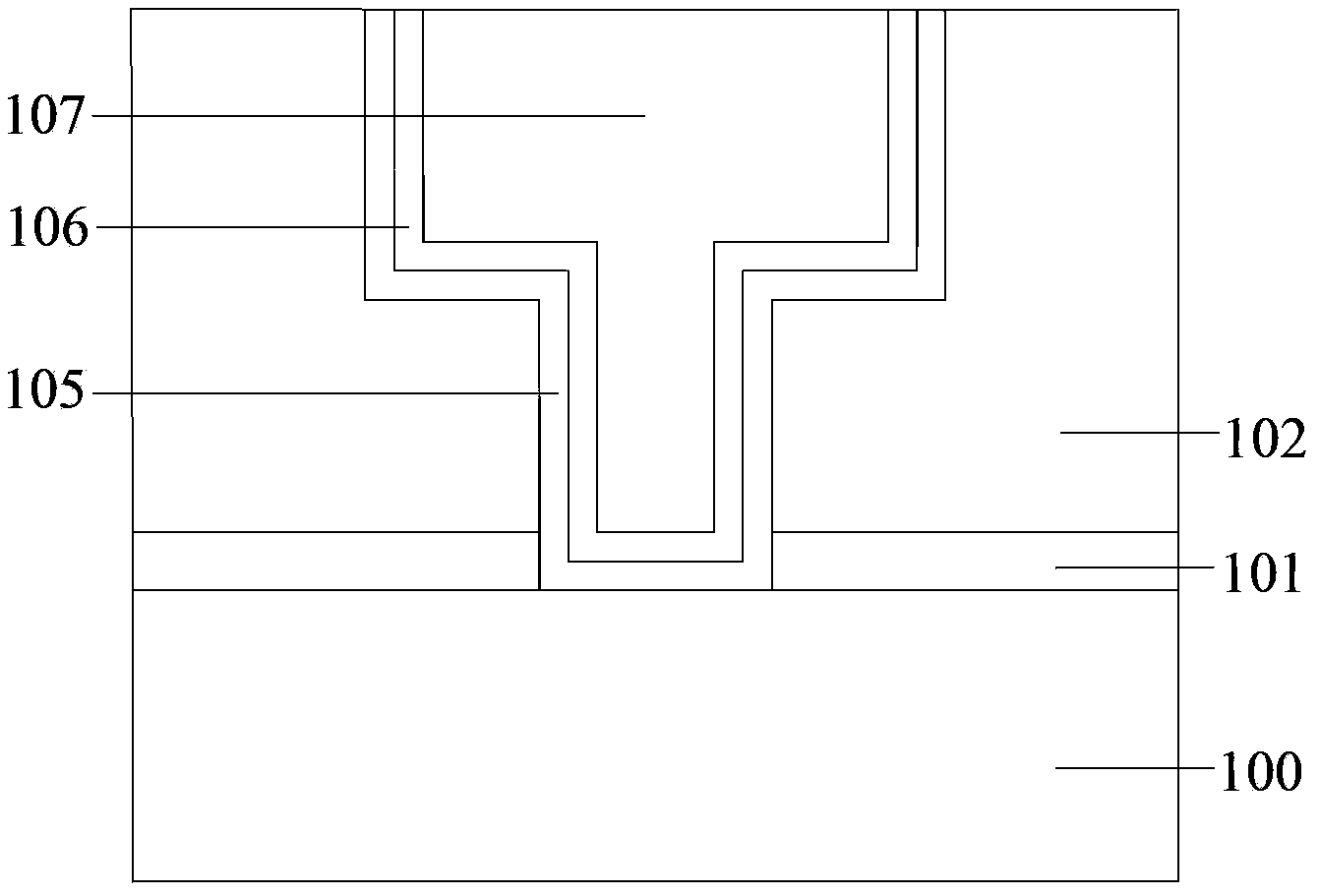

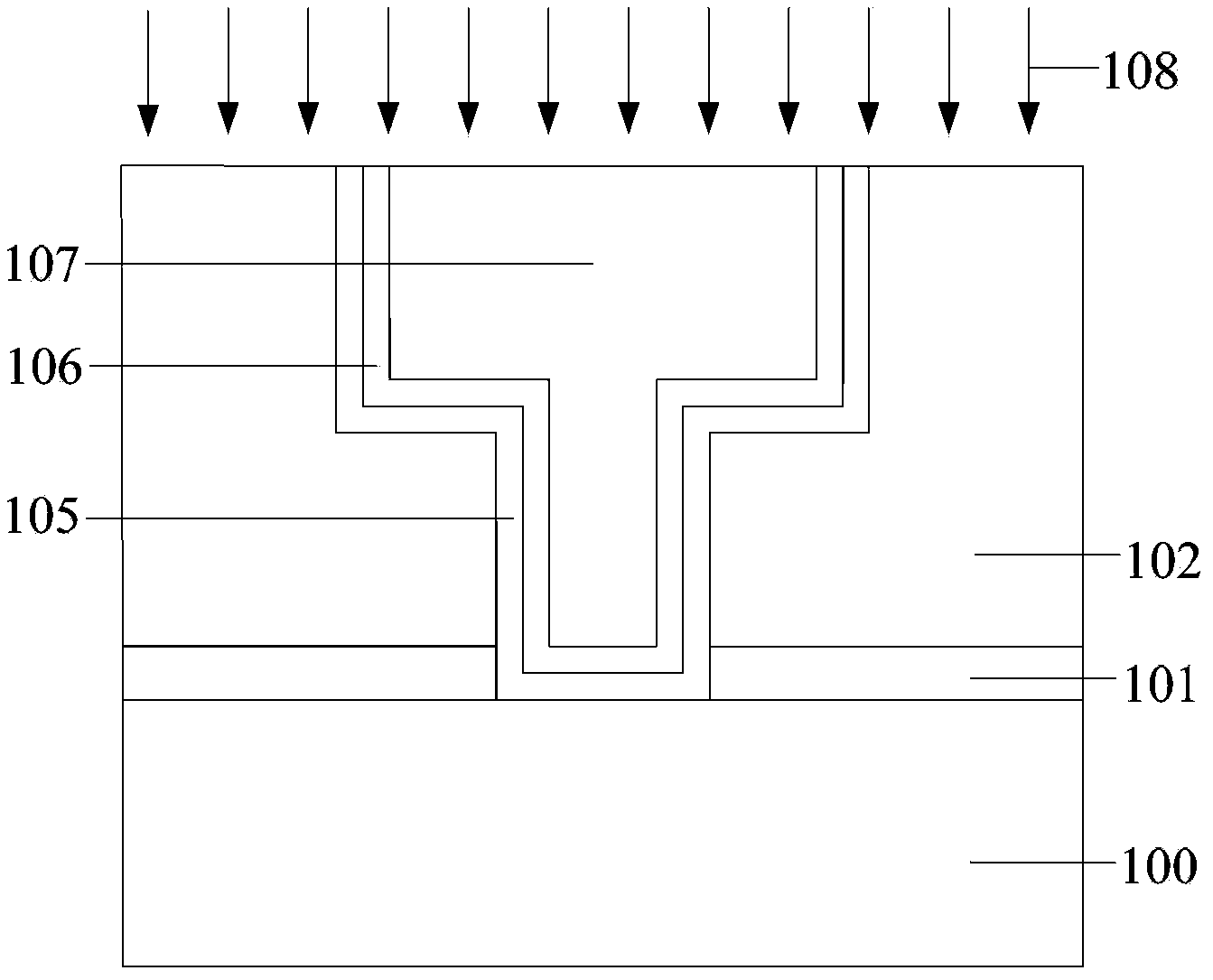

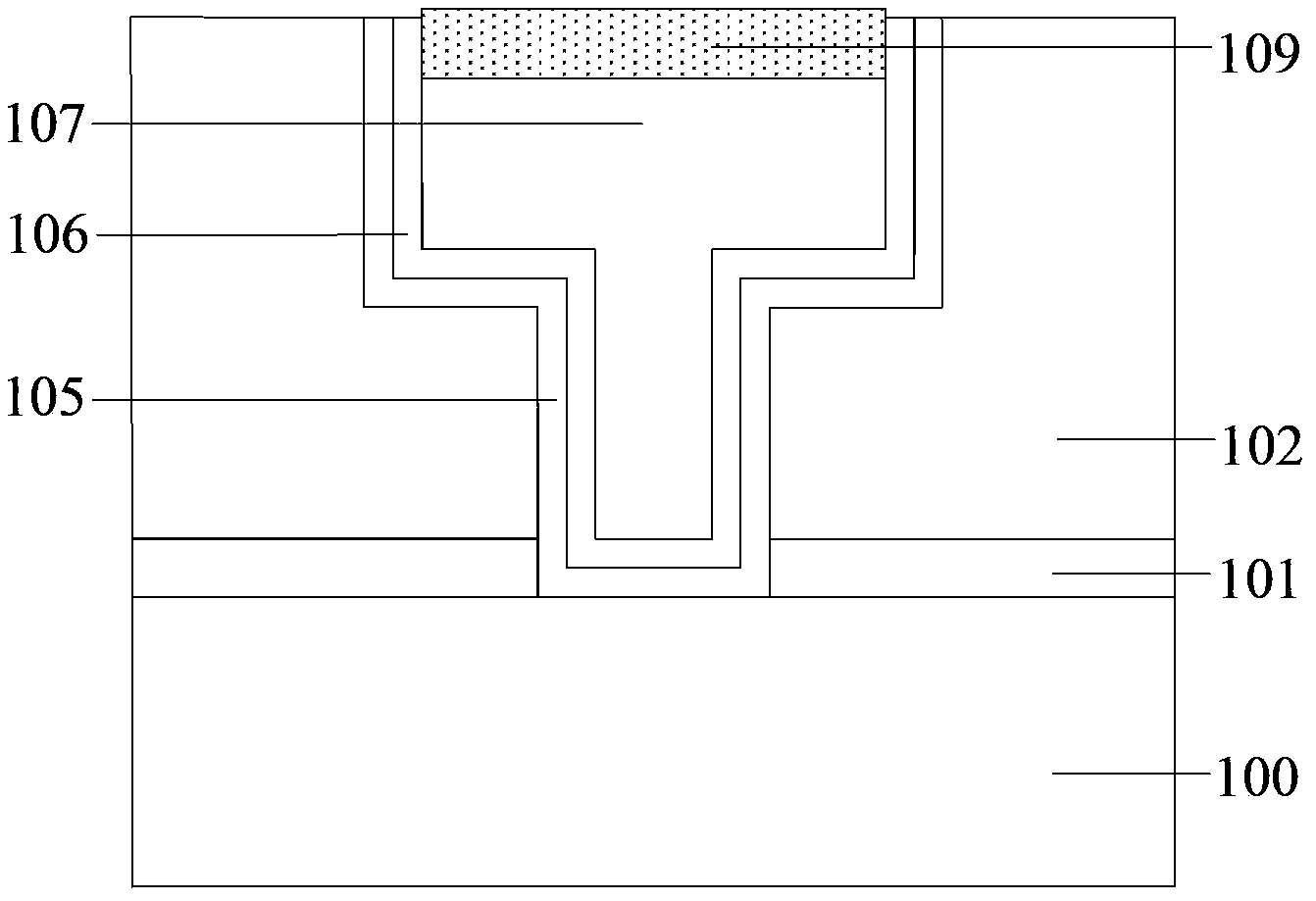

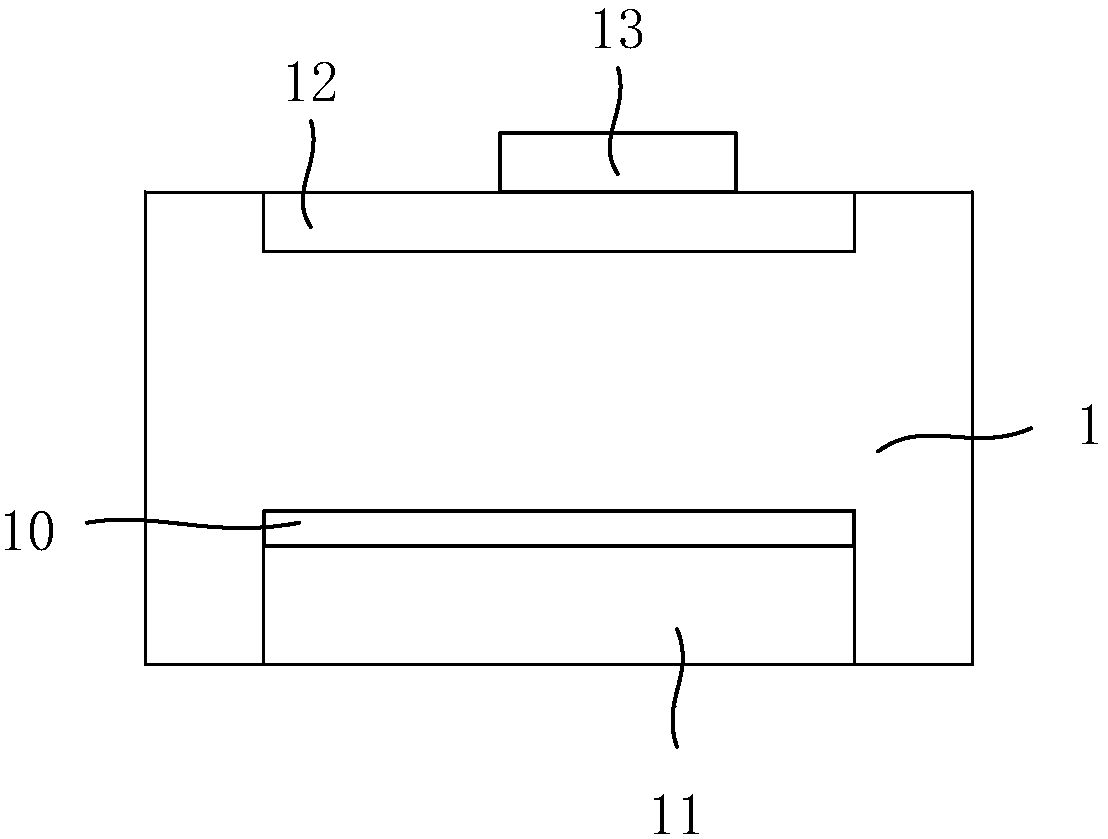

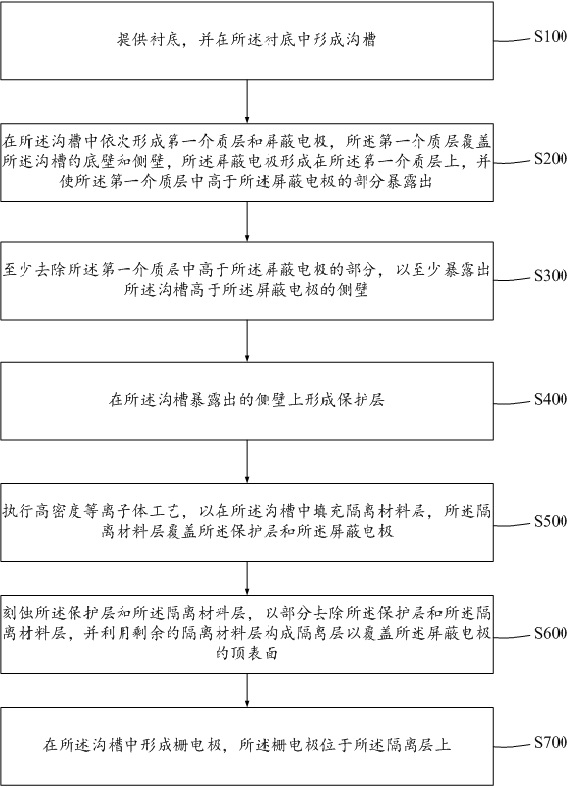

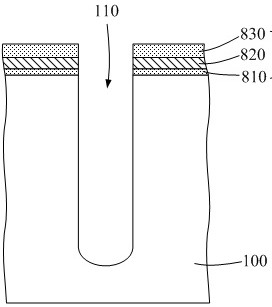

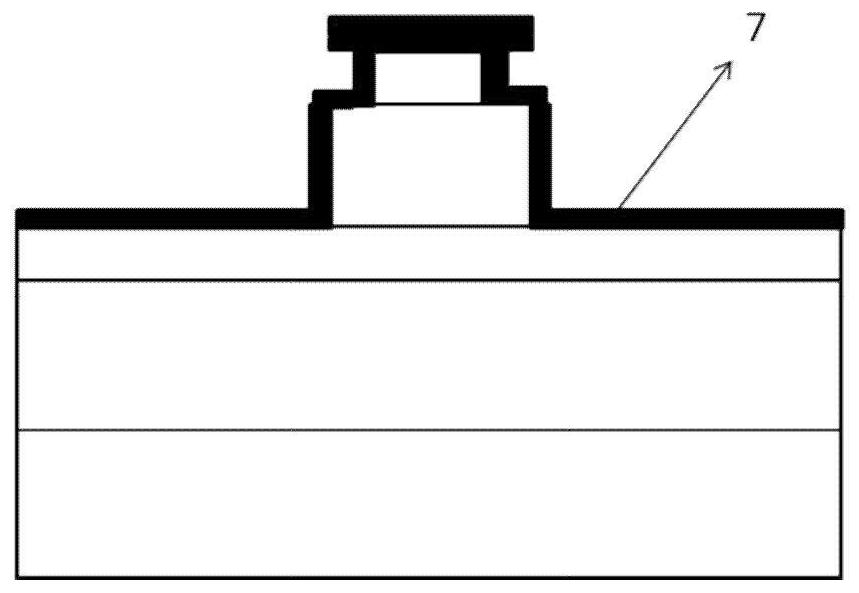

Shielded gate field effect transistor and method of forming the same

InactiveCN111681963BAvoid bombardmentInhibit injectionSemiconductor/solid-state device manufacturingSemiconductor devicesHigh densityField effect

The invention provides a shield gate field effect transistor and a forming method thereof. According to the forming method, a protection layer is formed on the side wall of a groove, so that the protection layer is used for preventing the side wall of the groove from being damaged by a high-density plasma process, plasma is prevented from being injected into the side wall of the groove, and the device performance of the prepared shield gate field effect transistor is guaranteed.

Owner:SEMICON MFG ELECTRONICS (SHAOXING) CORP

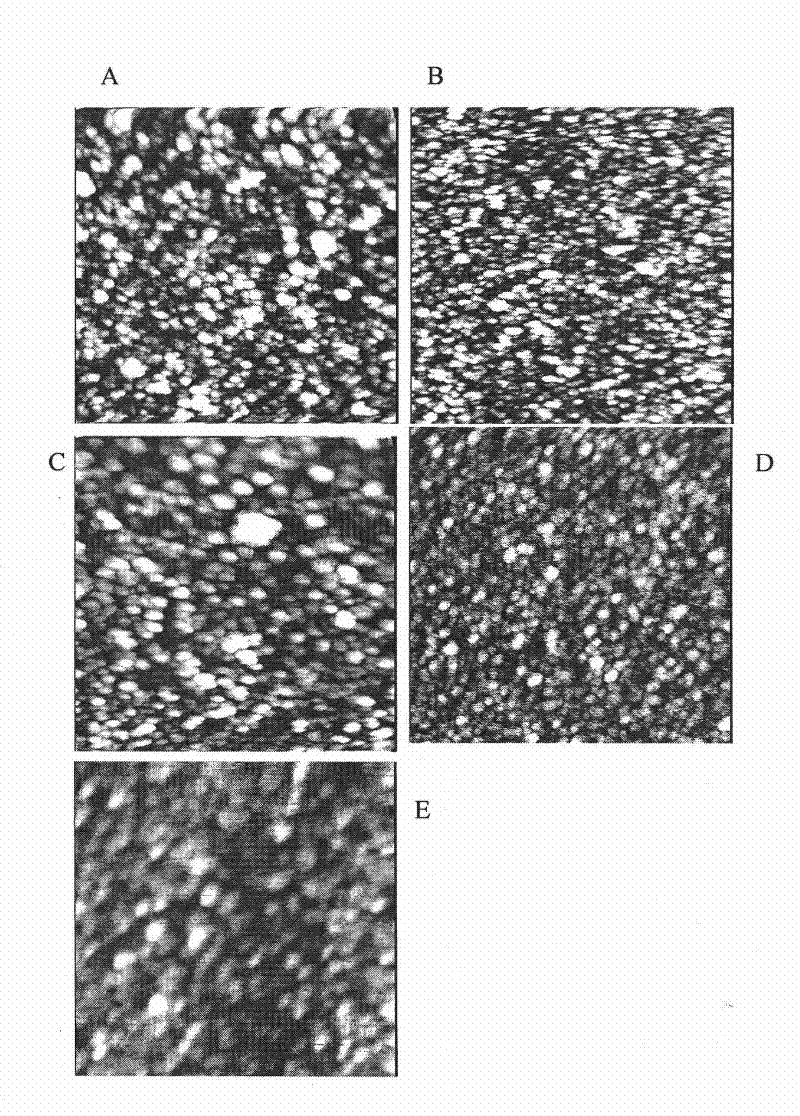

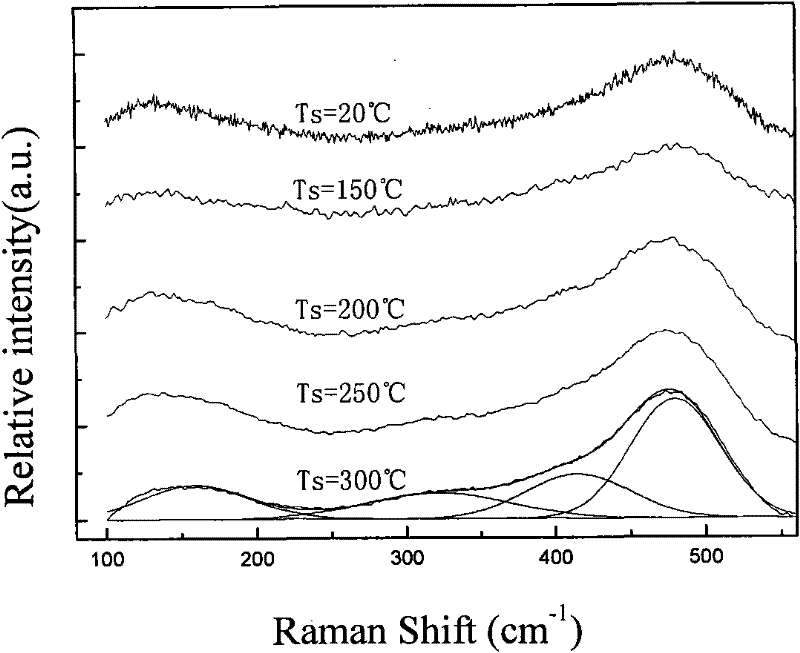

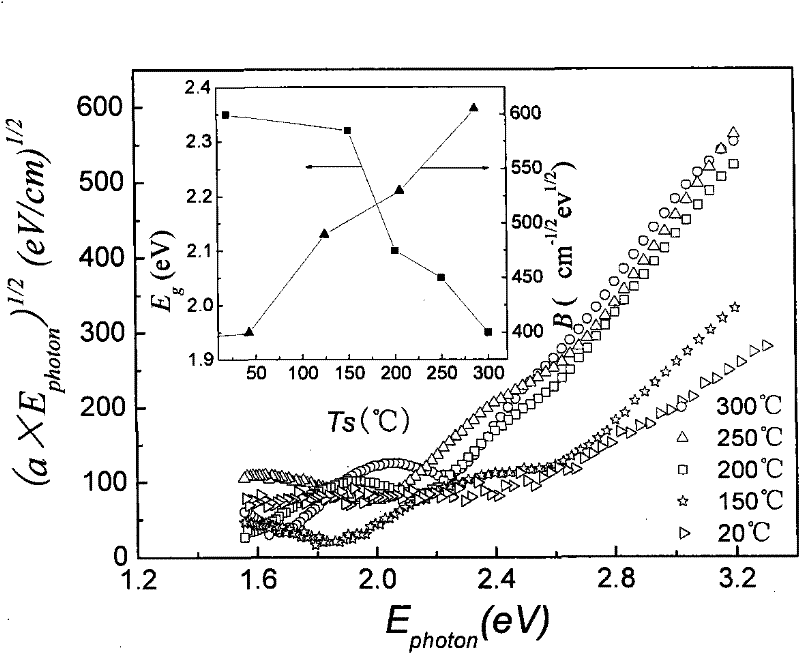

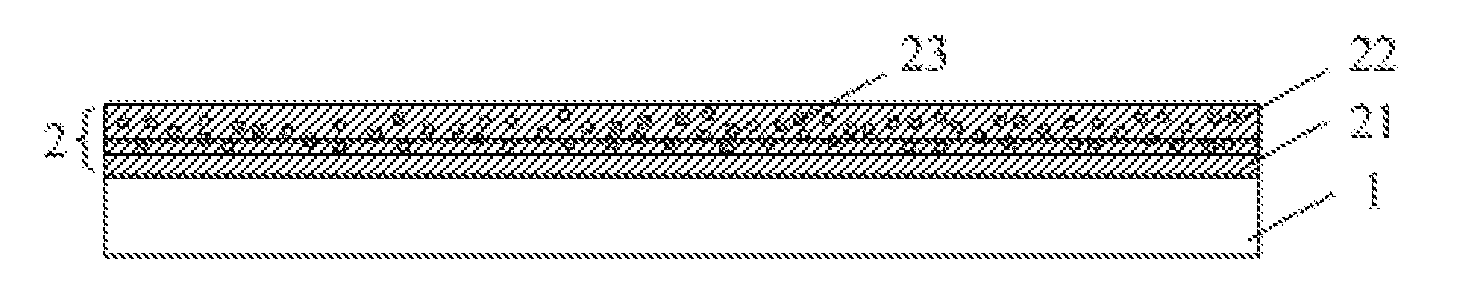

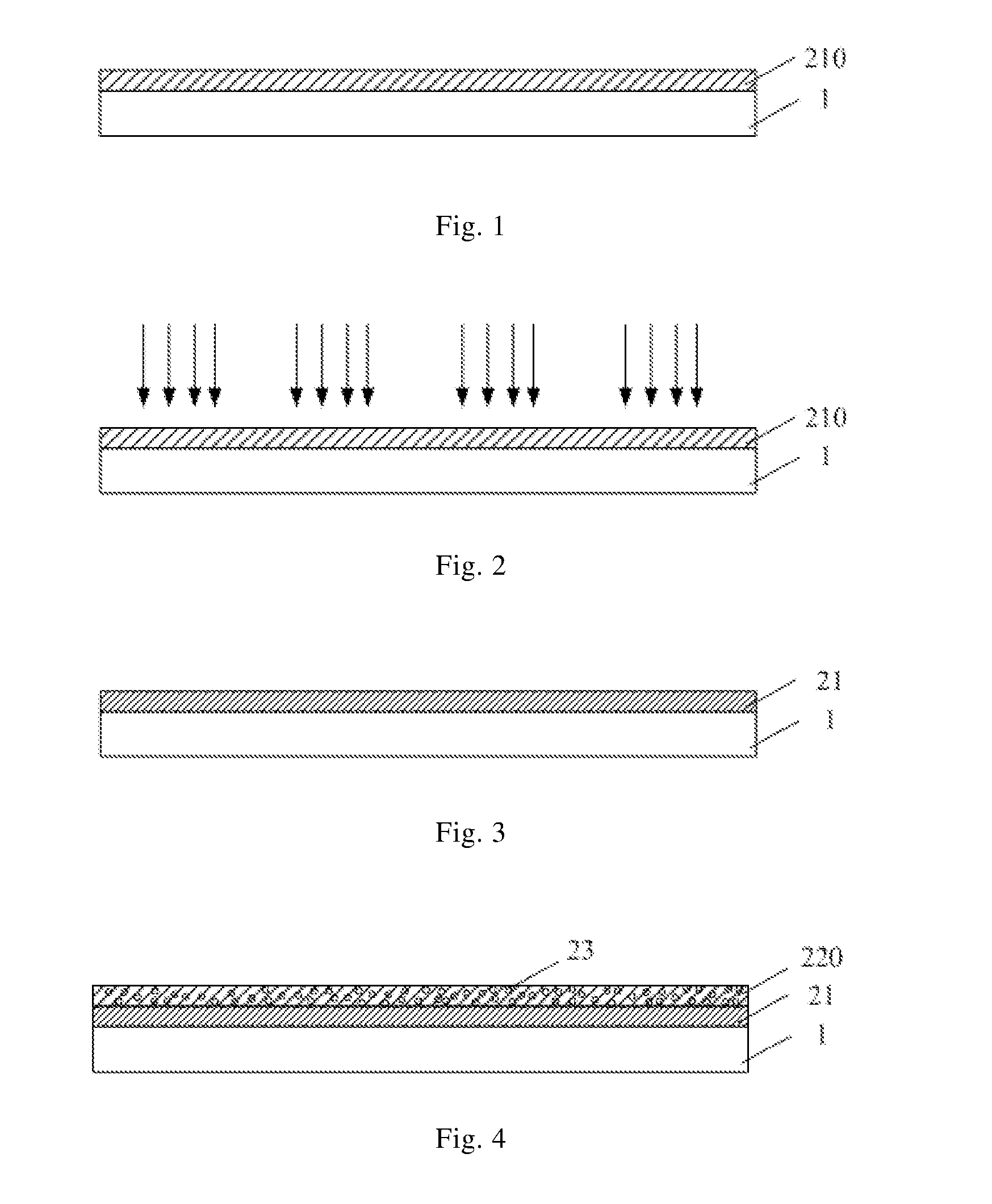

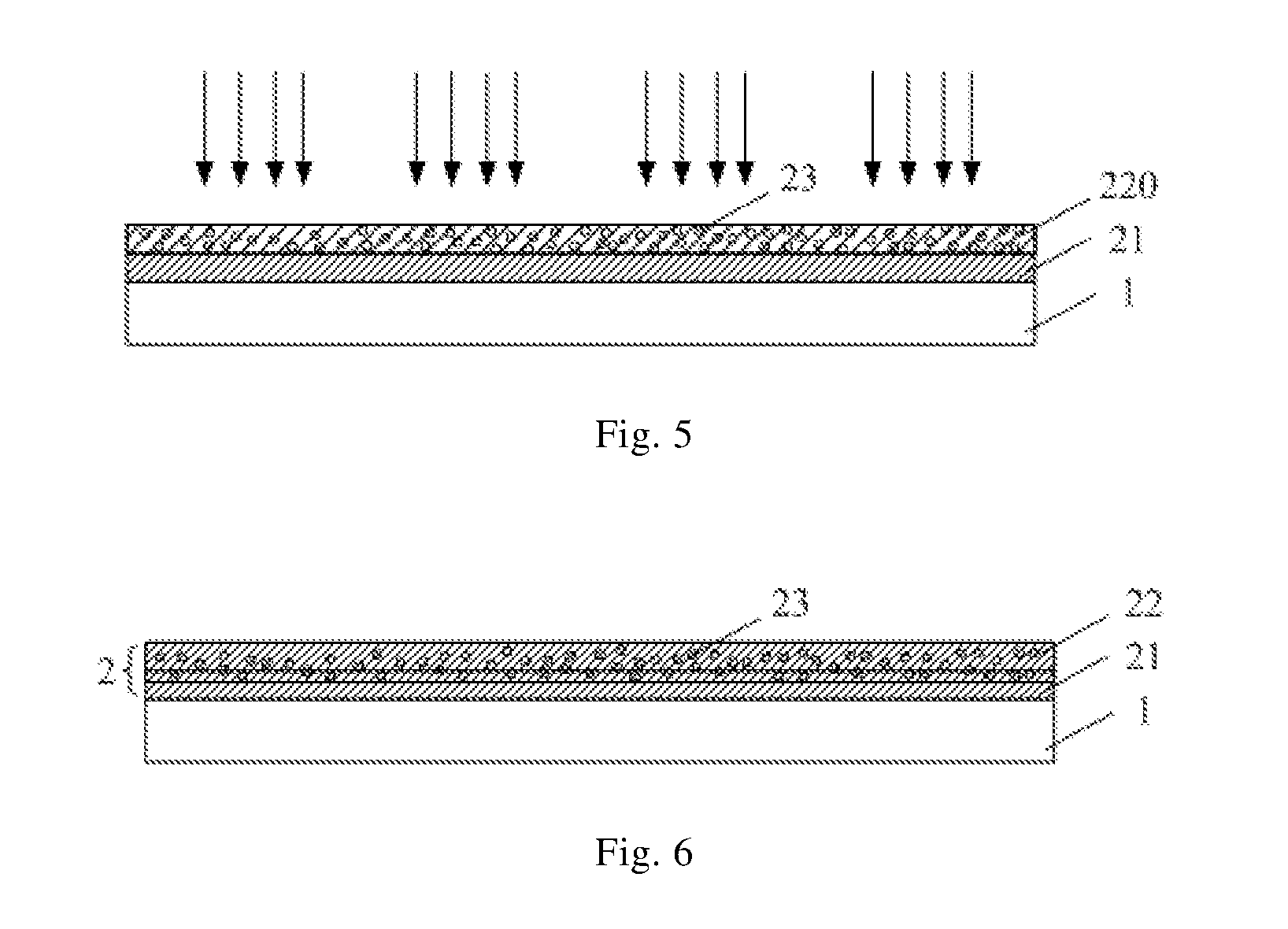

Method for rapidly depositing hydrogenated amorphous silicon solar battery thin film at low temperature

InactiveCN101834233BReduce the temperatureAvoid bombardmentFinal product manufactureVacuum evaporation coatingHydrogenAmorphous silicon solar cell

The invention discloses a method for rapidly depositing a hydrogenated amorphous silicon solar battery thin film at low temperature, which comprises the following steps of: firstly, placing a cleaned substrate on a substrate platform of an opposite target magnetron sputtering device; then vacuumizing a reaction chamber of the opposite target magnetron sputtering device and cleaning the substrate platform of the opposite target magnetron sputtering device and the wall of the reaction chamber by argon plasma; heating the substrate platform; charging a reaction gas into the reaction chamber and adjusting air pressure; starting a sputtering power supply and depositing the amorphous silicon thin film till an amorphous silicon thin film sample is obtained; finally cooling to room temperature under the protection of hydrogen, taking out the sample and finishing the deposition of the hydrogenated amorphous silicon thin film. The invention can rapidly deposit the hydrogenated amorphous siliconthin film at low temperature by utilizing an opposite target magnetron reaction sputtering deposition technology.

Owner:HEBEI UNIVERSITY

A method for covering a film in a hole and semiconductor processing equipment

ActiveCN109887879BImprove deposition efficiencyLower the altitudeSemiconductor/solid-state device manufacturingThin membraneEngineering physics

The invention provides a method for covering a film in a hole and semiconductor processing equipment. The method for covering a thin film in a hole comprises the following steps: step 1, depositing a thin film on the bottom and at least part of the side walls of the hole through a sputtering process; step 2, bombarding the positively charged process gas ions through an etching process The thin film at the bottom of the hole to increase the step coverage of the sidewall of the hole near the bottom. The method of covering the film in the hole can not only improve the process performance, but also take into account the production capacity of the equipment.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

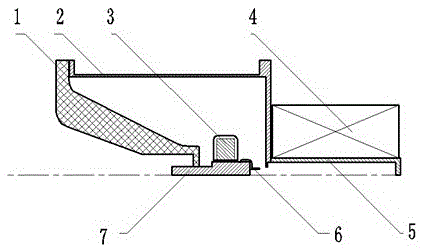

Semiconductor processing device and nozzle structure used in same

ActiveCN101585019BAvoid bombardmentImprove the excellent rateSpray nozzlesSemiconductor/solid-state device manufacturingPlasma densityMeasurement device

The invention relates to a semiconductor processing device and a corresponding nozzle structure, wherein a nozzle comprises a body of which an inner path is columnar; a gas inlet and a gas outlet are arranged on the body; the gas inlet is positioned on the edge of the upper part of the main body; the gas outlet is positioned on the bottom of the sidewall of the body; a gas flow channel is formed in the sidewall of the body or on the inner side of the sidewall; the gas flow channel is communicated with the gas inlet and the gas outlet; and the exit direction of the gas outlet is at an angle between 0 and 85 degrees to a center vertical line of the body. The invention can separate gas jetted downwards from the nozzle and a downward-irradiating optical path of an interference measurement device from each other, avoids bombardment to the nozzle because a place just below the nozzle is high in plasma density, then prevents the design of a gas nozzle from interfering in application effects of the interference measurement device, and provides more flexible space for the design and optimization of the gas nozzle so as to ensure that the nozzle is simple in structure and obvious in effects.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Manufacturing method of semiconductor laser vertical ridge structure capable of accurately controlling height

PendingCN114696216AReduce current injection areaImprove single-mode laser output efficiencyOptical wave guidanceErbium lasersPhotoresist

The invention provides a manufacturing method of a vertical ridge structure of a semiconductor laser capable of accurately controlling the height. The manufacturing method comprises the following steps: growing a semiconductor epitaxial film layer and an ESL; sequentially forming a primary silicon dioxide mask and a primary photoresist mask on the epitaxial wafer, and photoetching to form a periodic ridge window; carrying out ICP etching on the silicon oxide mask; continuously performing ICP etching on the epitaxial layer to a certain depth to form a narrow ridge structure; removing the residual photoresist; corroding the GaAs contact layer to form an internal shrinkage structure; growing and carrying out ICP etching on a silicon dioxide mask for the second time; performing wet etching on the epitaxial film layer to the corrosion barrier layer; after the mask is removed, growing a SiO2 current blocking layer, and forming a secondary photoresist mask pattern; and ICP etching is carried out to remove the current blocking layer at the top of the GaAs, a current injection window is exposed, and manufacturing of the ridge-shaped structure is completed. A dry etching and wet etching combined mode is adopted, the ridge height can be accurately controlled, the side wall is vertical, meanwhile, a current injection area on a ridge strip is reduced, and the current injection density is improved.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

Thin film transistor, manufacturing method thereof, array substrate, and display device

ActiveUS20170040464A1Improve stabilityInterface in thinTransistorSolid-state devicesTransistor arrayDopant

Embodiments of the present invention disclose a manufacturing method of a thin film transistor, a thin film transistor, an array substrate and a display device. The manufacturing method of a thin film transistor includes a step of forming an active layer, and the step of forming an active layer includes: forming a first poly-silicon layer and a second poly-silicon layer on the first poly-silicon layer separately, and adding dopant ions into the second poly-silicon layer and an upper surface layer of the first poly-silicon layer. By using the manufacturing method of a thin film transistor, defect states and unstable factors of interface in the thin film transistor can be reduced, thereby improving stability of the LTPS thin film transistor and obtaining an array substrate and a display device having more stable performance.

Owner:BOE TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com