Emitting laser for etching top end non-doping intrinsic layer asymmetric metal membrane vertical cavity surface

A vertical cavity surface emission, metal film technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of inability to achieve a small current aperture, uncontrollable oxidation of small apertures, and limited development, to improve optoelectronic coupling. efficiency, improve luminous efficiency, reduce the effect of area recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

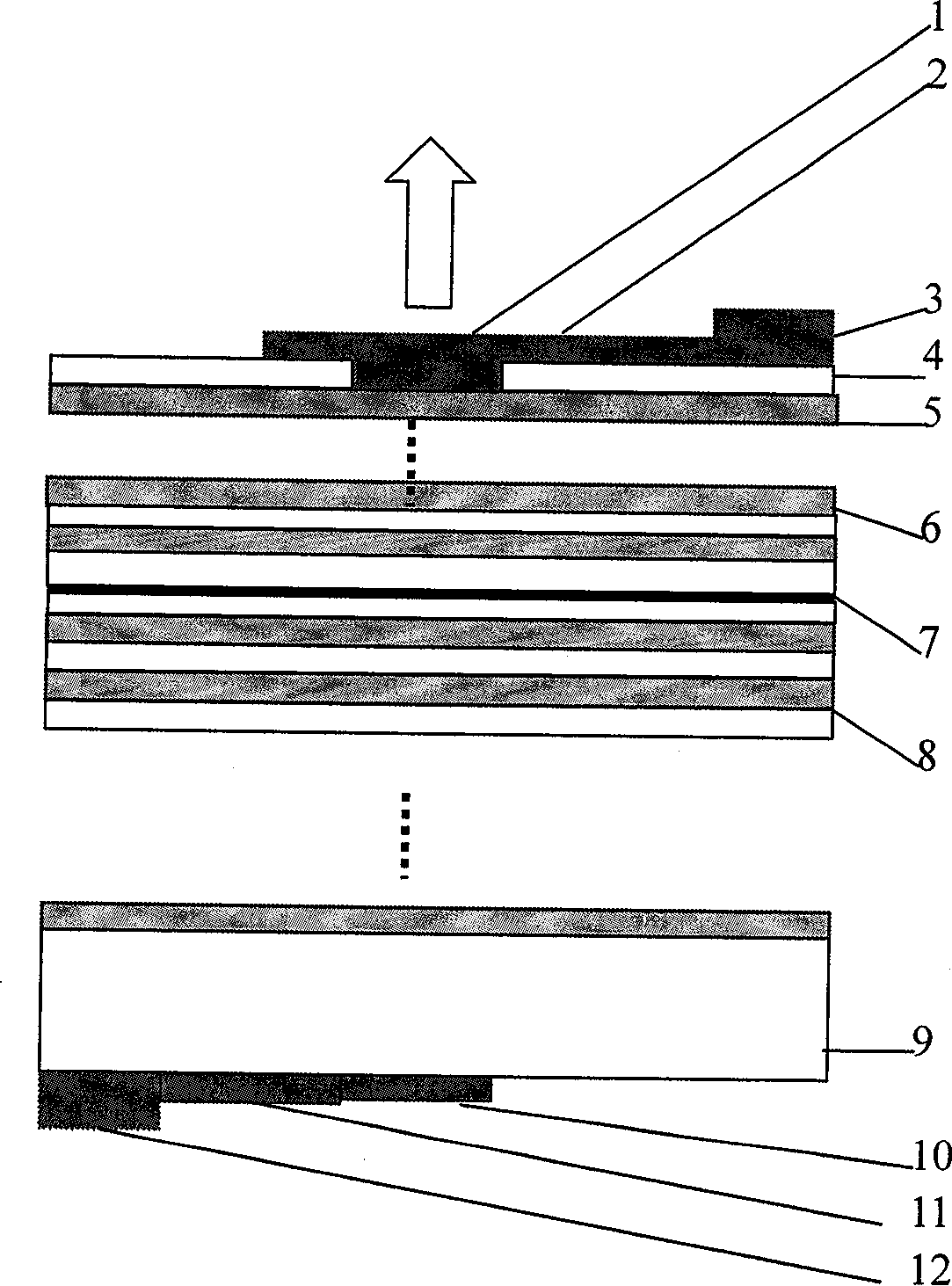

[0039] The present invention is described in detail below in conjunction with accompanying drawing:

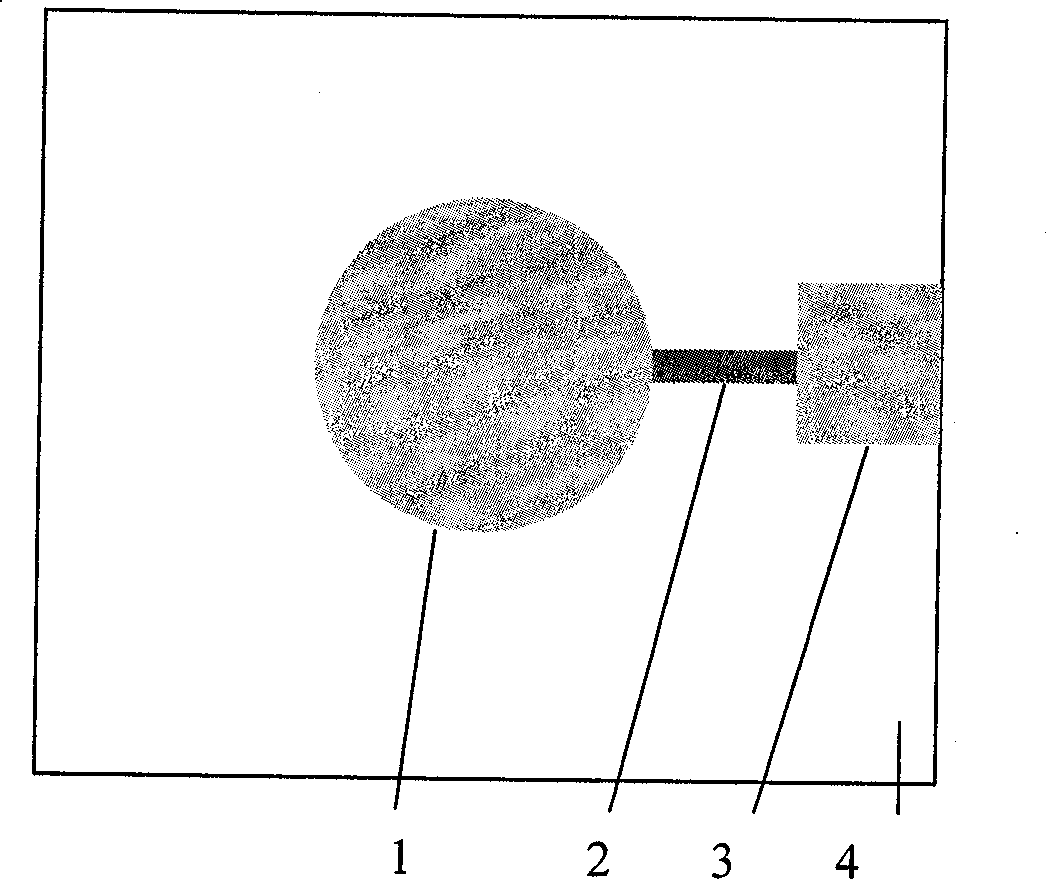

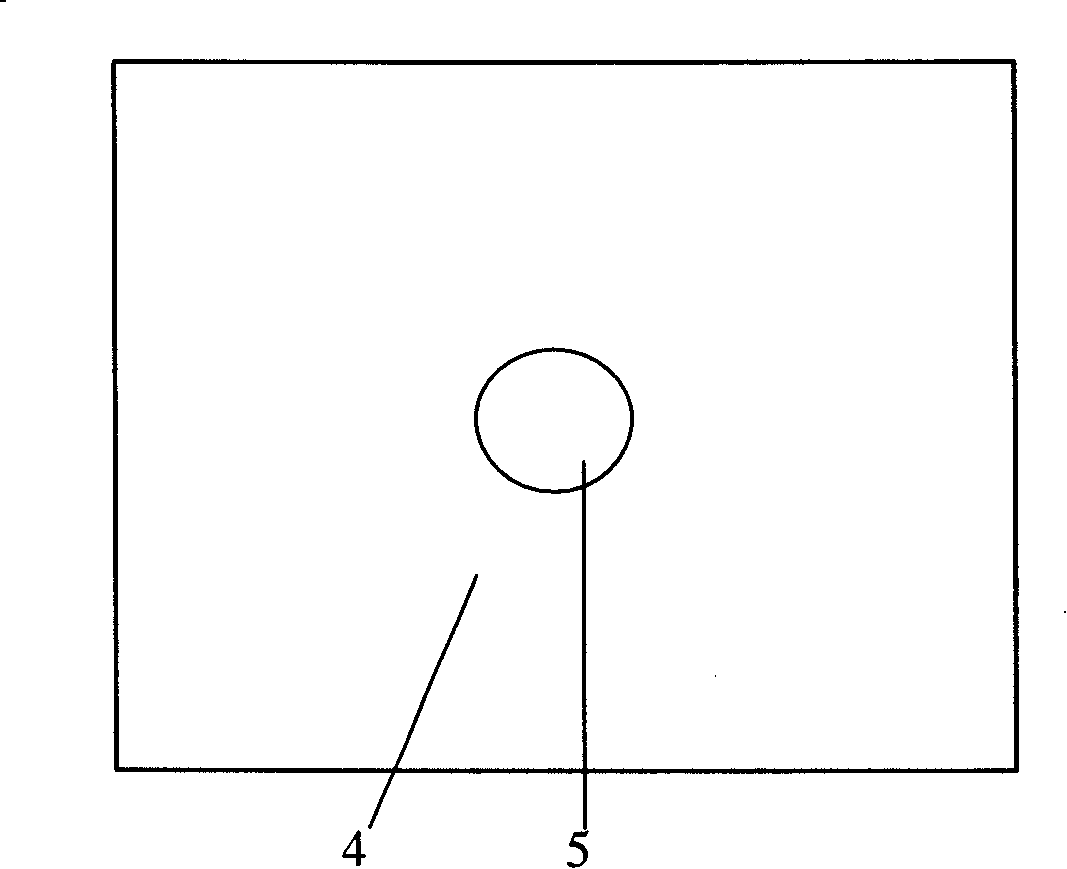

[0040] as the picture shows, figure 1 It is a structural schematic diagram of the product of the present invention; figure 2 The top view of the upper electrode and the top metal film etching area of the vertical cavity surface emitting laser with etched metal film; image 3 Top view of the undoped intrinsically high-resistance region of the etched current aperture, Figure 4 Bottom view of the bottom electrode and the etched area of the metal-plated film of the etched metal film vertical cavity surface emitting laser.

[0041] Among them, 1: the circular metal reflective film etched on the upper surface, with a radius of 4 to 8 microns; 2: the metal film wire etched on the upper surface; 3: the metal film and electrode in contact with the etched electrode on the upper surface; Doped intrinsically high resistance semiconductor material, the radius of the hole is 1-2 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com