Method for rapidly depositing hydrogenated amorphous silicon solar battery thin film at low temperature

A technology of hydrogenated amorphous silicon and solar cells, which is applied in the direction of circuits, electrical components, ion implantation plating, etc., can solve the problems of slow growth of thin film layers, high commercialization costs, and doping of thin films, so as to achieve fast deposition speed and avoid Bombardment, effect of low substrate temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

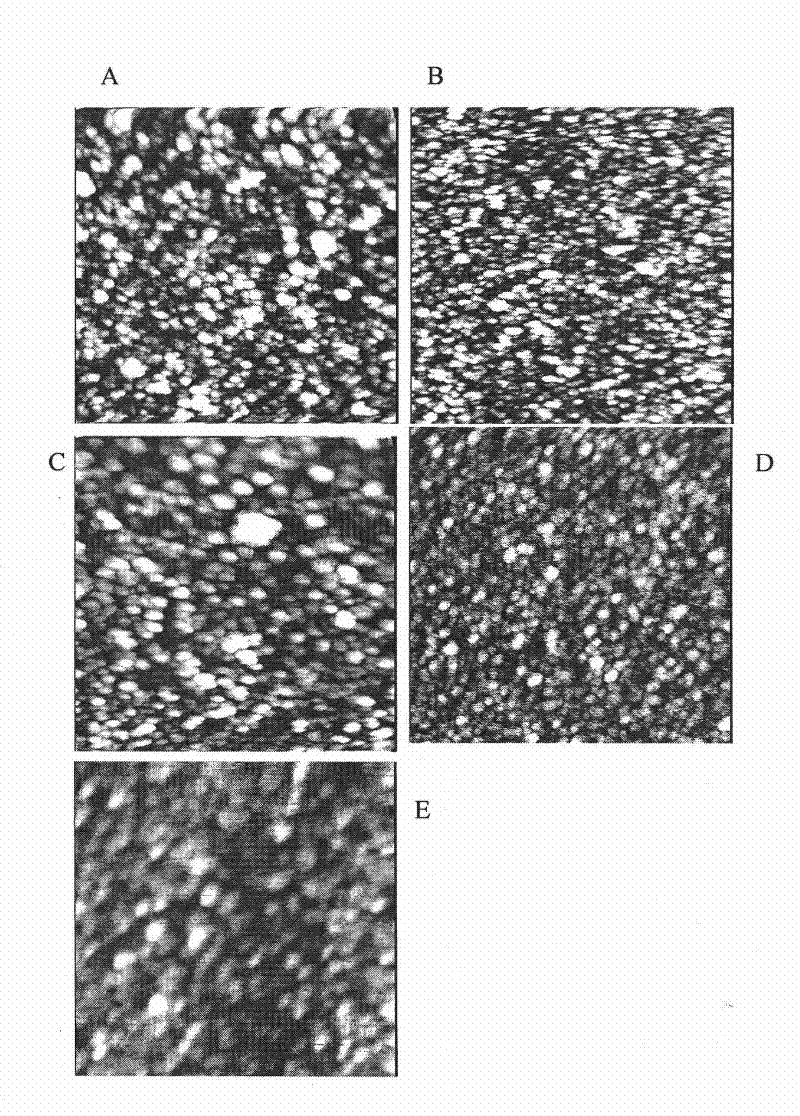

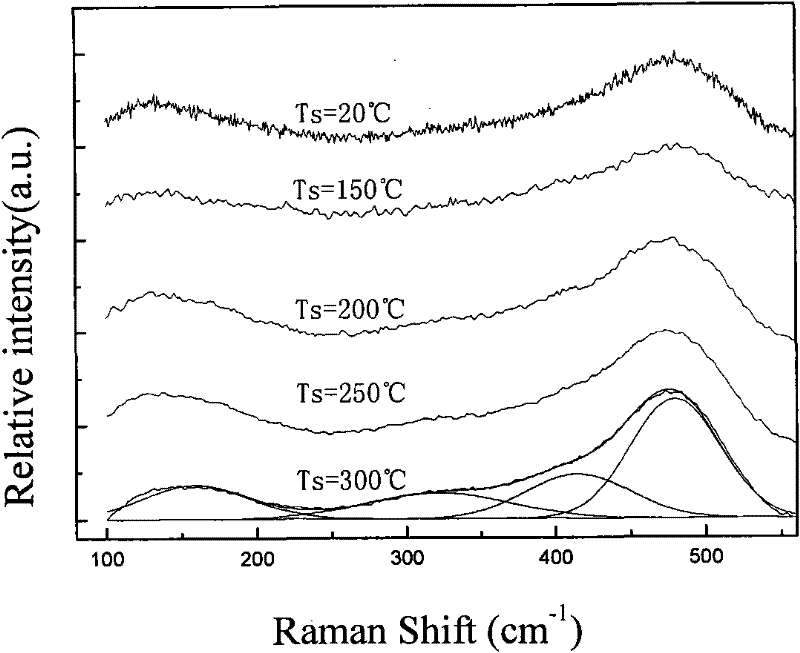

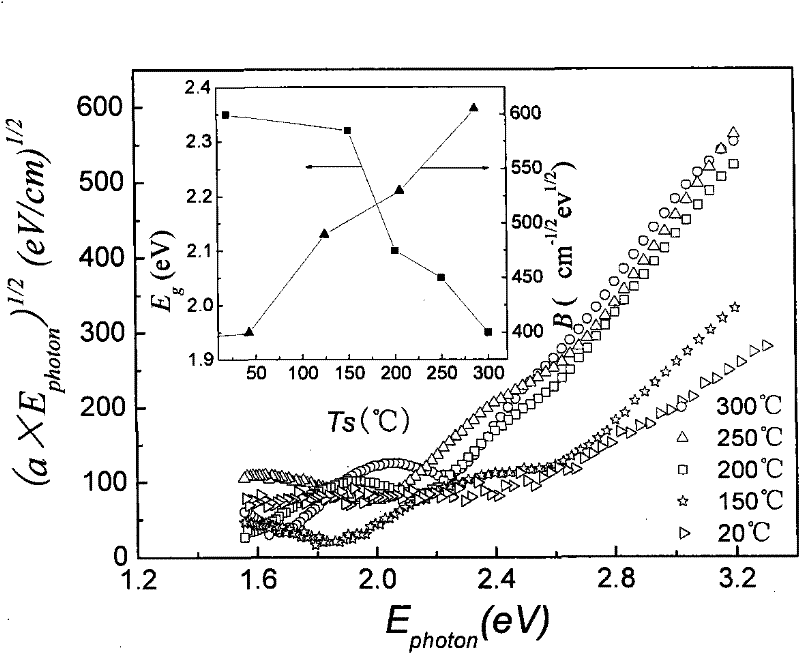

Image

Examples

Embodiment 1

[0023] The method for depositing hydrogenated amorphous silicon solar cell thin films at low temperature and high speed according to the first embodiment of the present invention comprises the following steps:

[0024] A. Take a single crystal silicon wafer substrate, soak it in a mixture of acetone and methanol for 3 minutes, take it out and dry it, and then use the volume ratio NH 4 OH:H 2 o 2 :H 2 Soak in the mixed solution of O=1:2:5 for 5 minutes, take it out and rinse it with deionized water, and then put it in the volume ratio HF:H 2 Soak in the mixed solution of O=1:10 for 1 minute, take it out, rinse it with deionized water, dry it, and then place the substrate on the substrate stage of the magnetron reactive sputtering deposition device for the target;

[0025] B. Use the vacuum pumping system to evacuate the reaction chamber of the target magnetron reactive sputtering deposition device, so that the reaction chamber pressure is lower than 5×10 -4 Pa;

[0026] C....

Embodiment 2

[0030] The method for depositing hydrogenated amorphous silicon solar cell thin film at low temperature and high speed in the second embodiment of the present invention has the same steps as in embodiment 1, except that the substrate stage is heated to 150° C. in step 1-D.

Embodiment 3

[0032] The method for depositing a hydrogenated amorphous silicon solar cell thin film at low temperature and high speed in the third embodiment of the present invention has the same steps as in embodiment 1, except that the substrate stage is heated to 200° C. in step 1-D.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com