Preparation apparatus and preparation method of graphene

A technology for preparing devices and graphene, which is applied in the direction of graphene, nano-carbon, etc., can solve the problems of limiting the development of plasma reduction technology, thinning, etc., and achieve the effect of reducing structural defects, avoiding bombardment and etching, and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

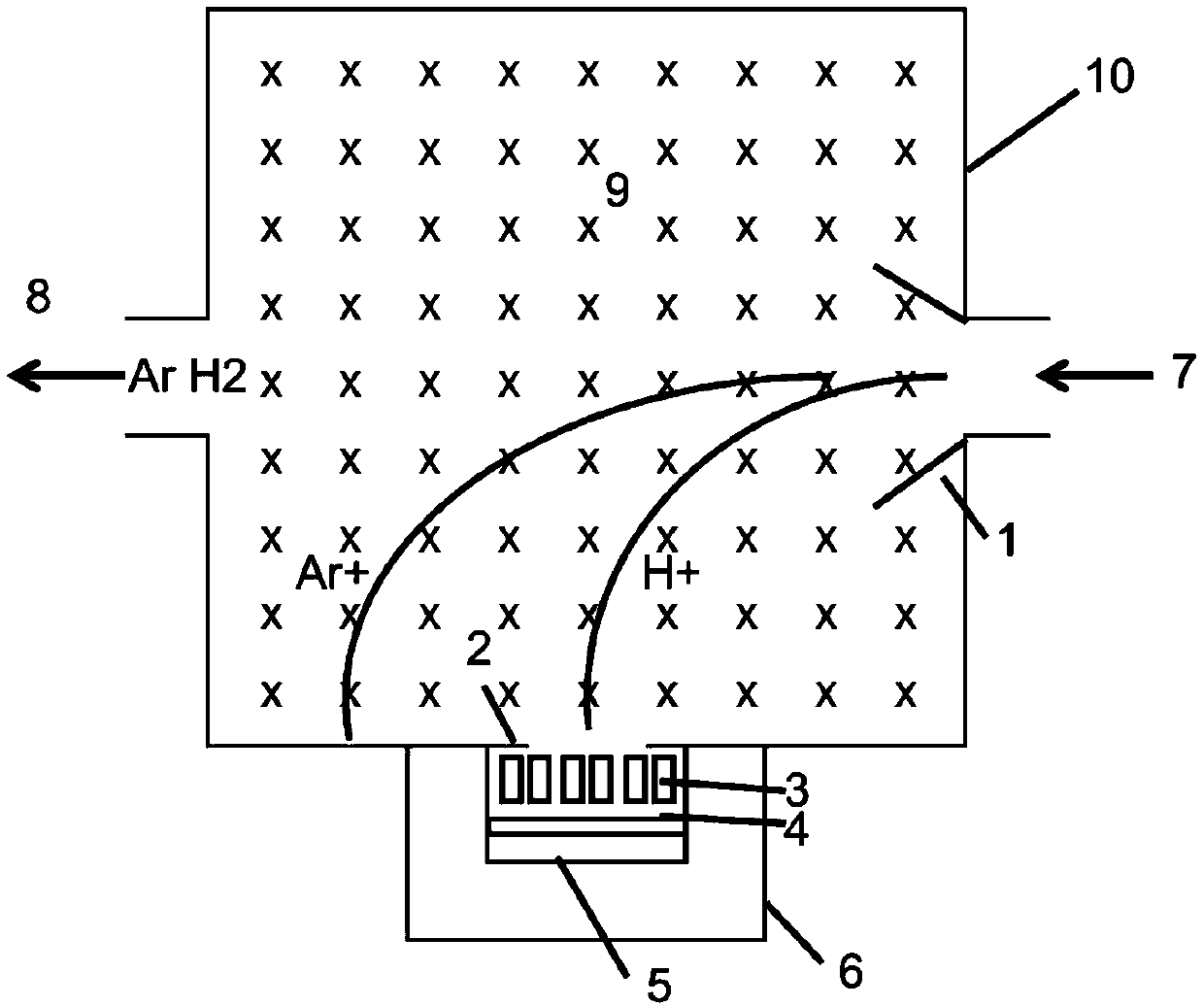

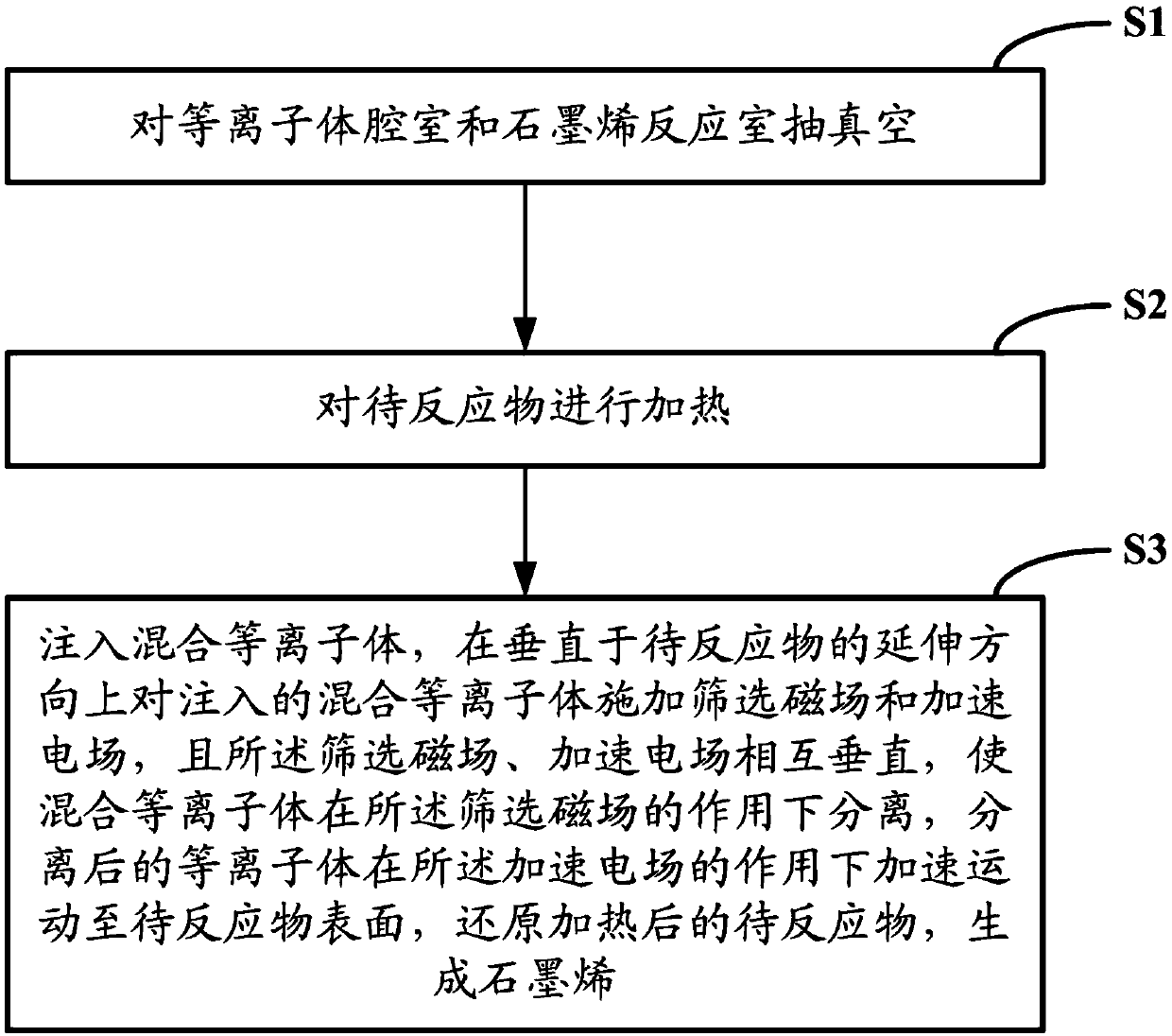

[0045] Such as figure 2 Shown according to the preparation method of graphene of the present invention comprises:

[0046] S1, vacuumize the plasma chamber and the graphene reaction chamber;

[0047] S2, heating the reactants;

[0048] S3. Injecting mixed plasma, applying a screening magnetic field and accelerating electric field to the injected mixed plasma in a direction perpendicular to the extension direction of the reactants, and the screening magnetic field and accelerating electric field are perpendicular to each other, so that the mixed plasma is separated under the action of the screening magnetic field , the separated plasma accelerates to the surface of the reactant under the action of an accelerating electric field, and reduces the heated reactant to generate graphene.

[0049] Step S1 and step S2 can be performed at the same time, step S1 can be performed first and then step S2 can be performed, or step S2 can be performed first and then step S1 can be performe...

Embodiment 1

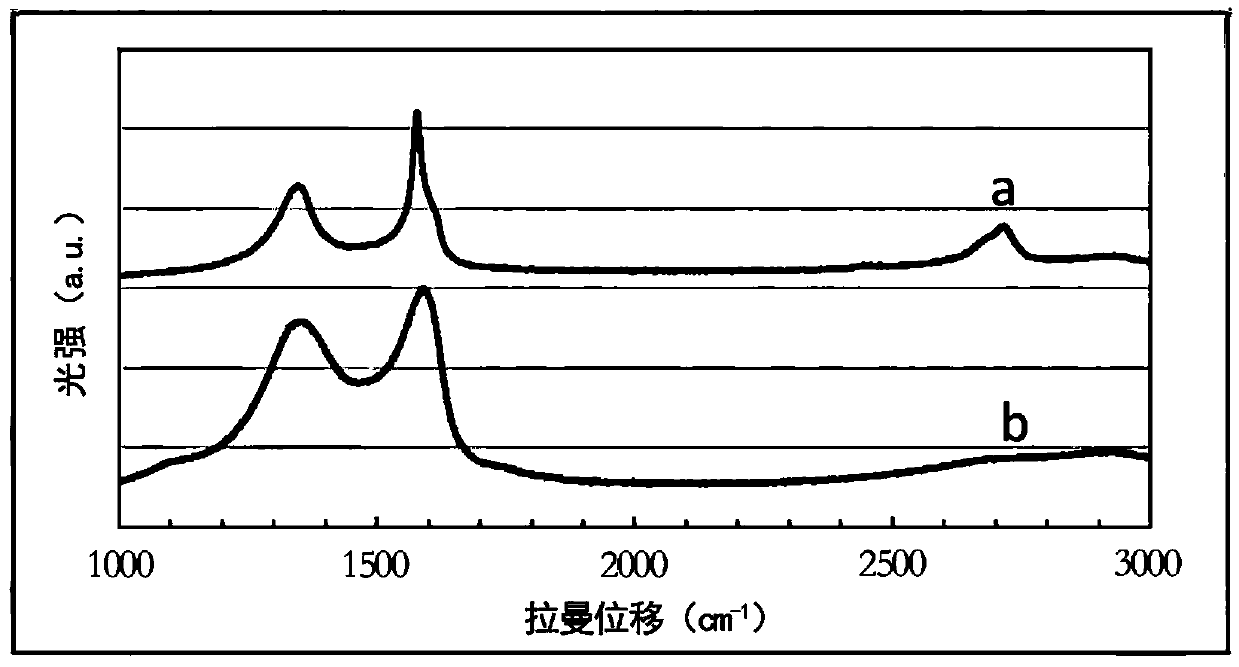

[0054] The preparation of embodiment 1 graphene

[0055] The plasma chamber 10 and the graphene reaction chamber 6 are evacuated and kept within a vacuum range of about 50-70Pa;

[0056] The heating plate 5 is heated by an alternating current of an appropriate frequency, and the graphene oxide film (glass substrate) is at a temperature of about 200°C;

[0057] The mixed gas source 7 (hydrogen and argon) is processed by the plasma generator to form a mixed plasma, which has 3×10 after passing through the plasma injection port 2 3 The initial velocity of m / s, then enters the screening magnetic field 9 in the plasma chamber 10 (the size of the magnetic field is about 10Gs);

[0058] Assuming that the average velocity of each ion is the same, each ion moves in a circle under the action of a magnetic field, the radius of motion of the hydrogen ion is about 3.0 cm, the horizontal distance between the center of the slit and the plasma injection port 2 is 3.0 cm, and the width of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com