Pre-cleaning cavity and semiconductor processing device

A pre-cleaning and chamber technology, which is applied in the field of pre-cleaning chambers and semiconductor processing equipment, can solve the problems of reducing product yield and wafer surface contamination, so as to improve yield, reduce metal ion pollution, and weaken radial electric field strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

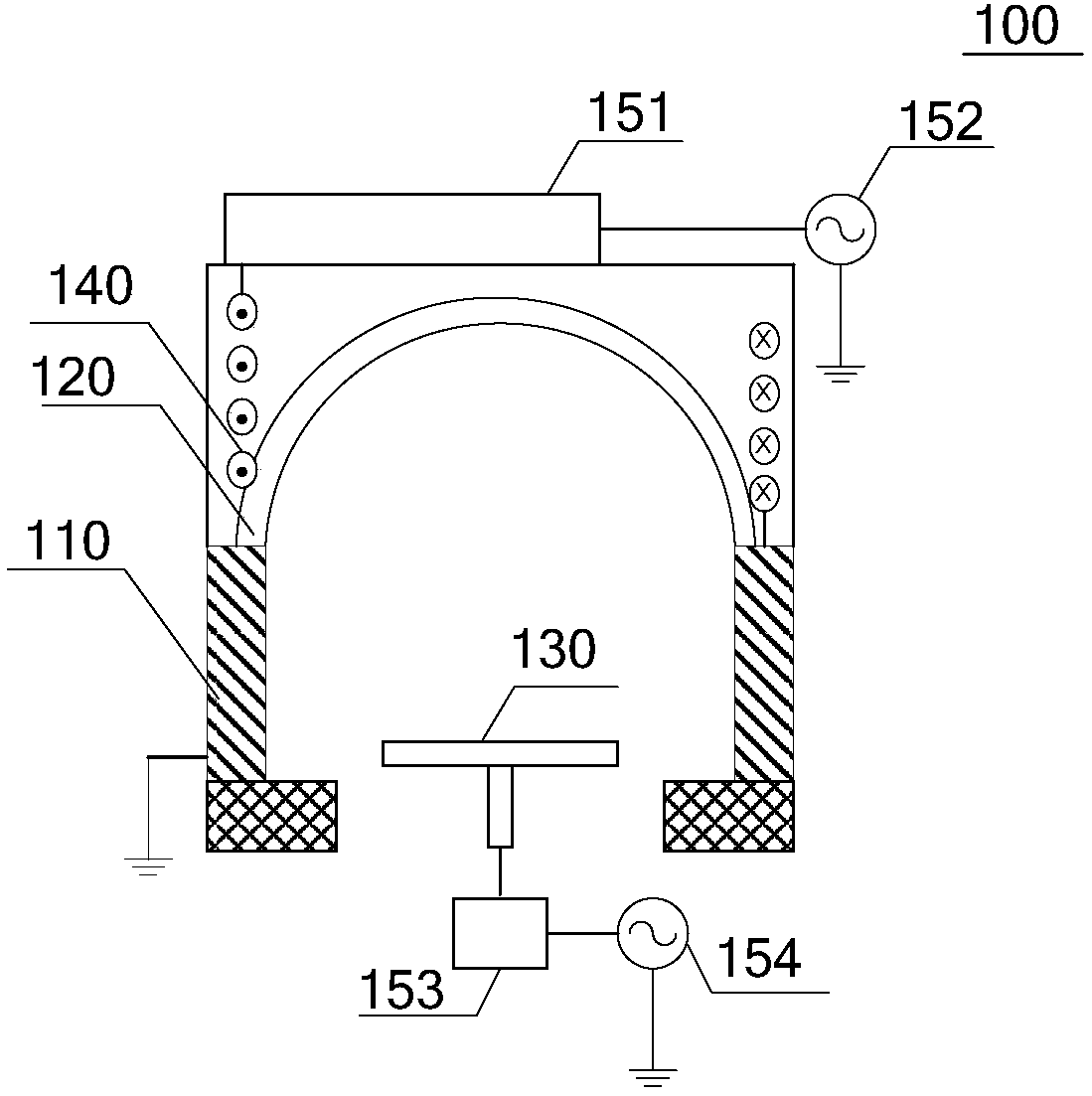

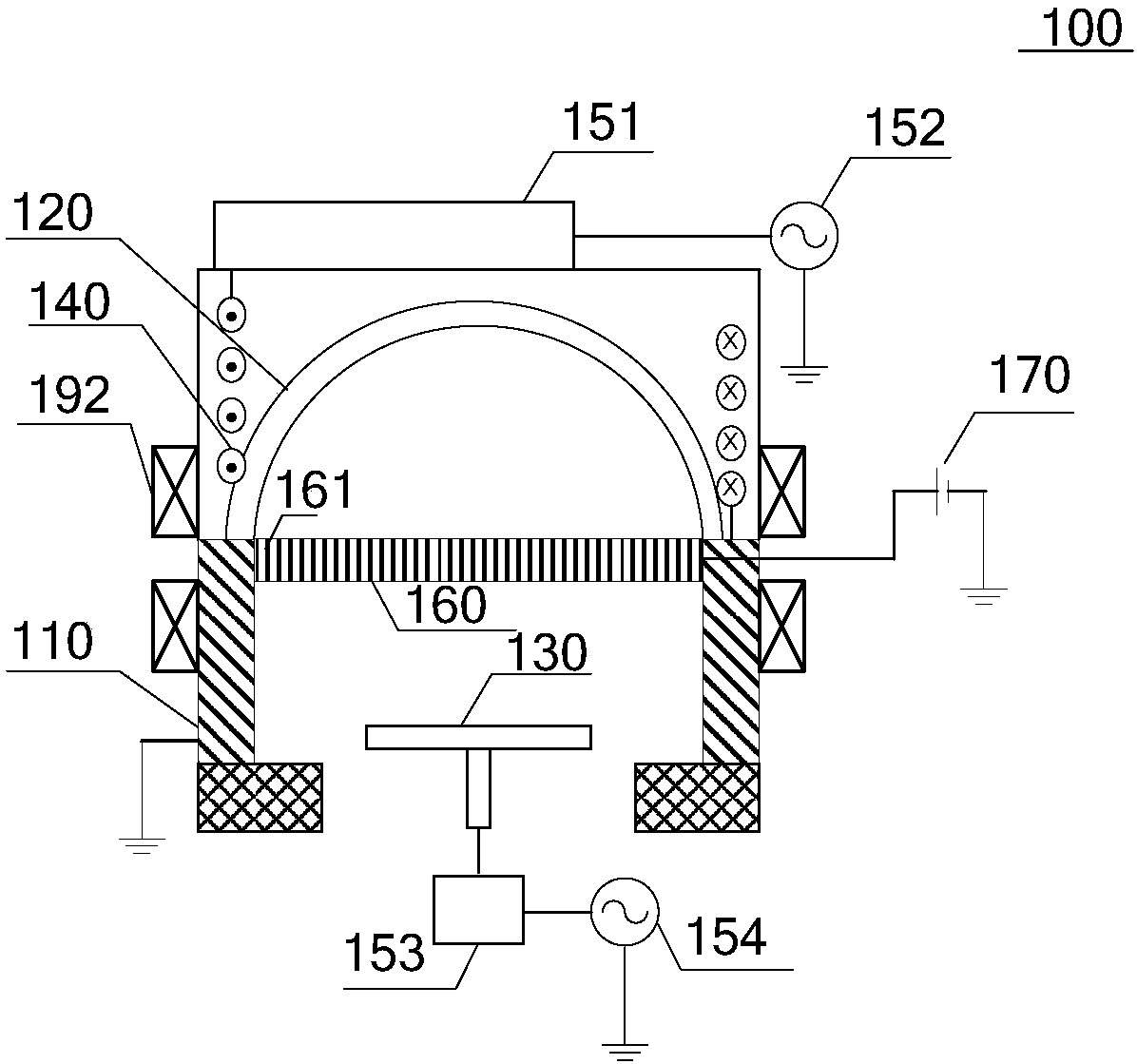

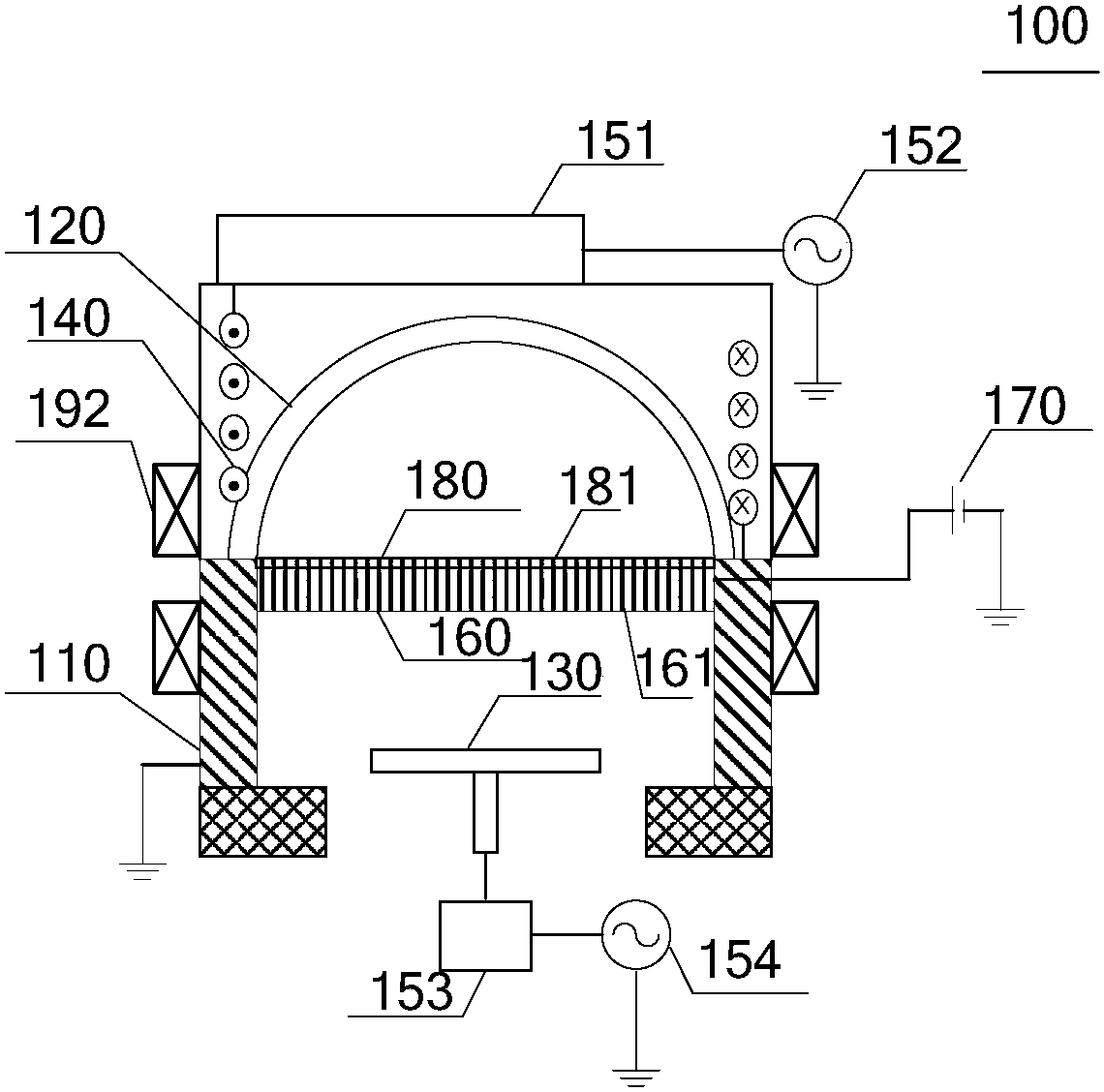

[0051] Such as image 3 , Figure 4 with Figure 5 As shown, the first aspect of the present invention relates to a pre-cleaning chamber 100 . The pre-cleaning chamber 100 mainly includes a cavity 110, a top cover 120, a carrier 130, an inductance coil 140, a first radio frequency matching device 151, a first radio frequency power source 152, a second radio frequency matching device 153 and a second radio frequency power source 154 . Wherein, the top cover 120 is disposed on the top of the cavity 110 , that is, the top cover 120 is disposed on the top of the cavity 110 to enclose a sealed space together with the cavity 110 . The cavity 110 can be columnar, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com