Touch screen, touch screen manufacturing method and display device

A touch screen and touch technology, applied in instruments, electrical digital data processing, input/output process of data processing, etc., can solve the problems of contamination chambers, surface protrusions and depressions, poor process, etc., so as to avoid contamination chambers. room, the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

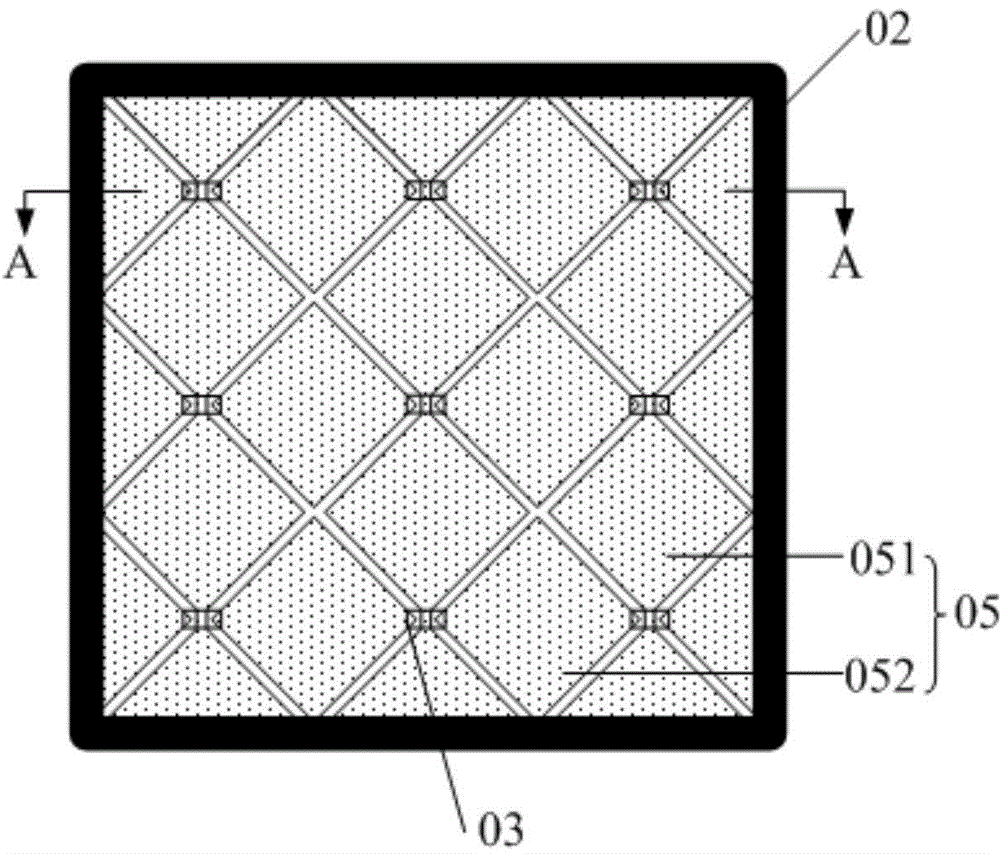

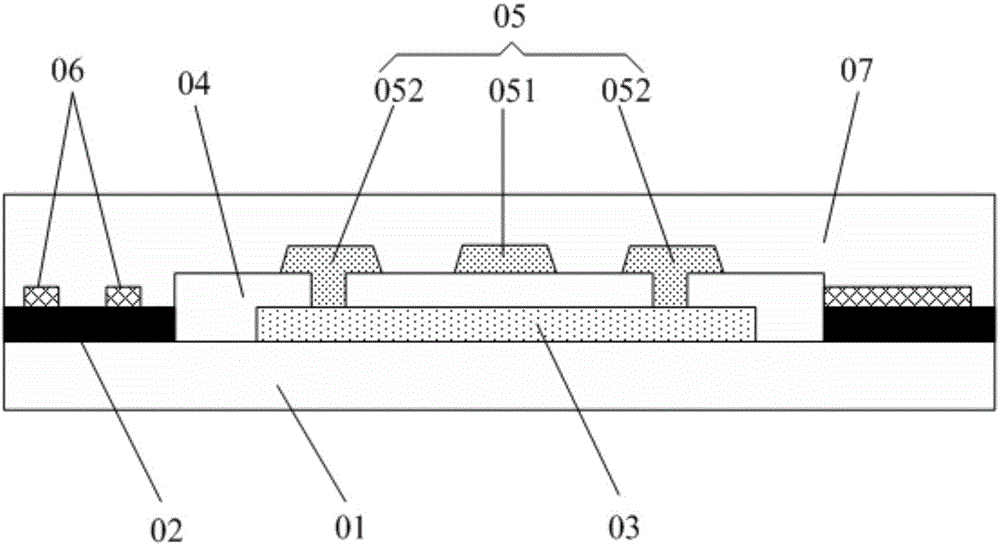

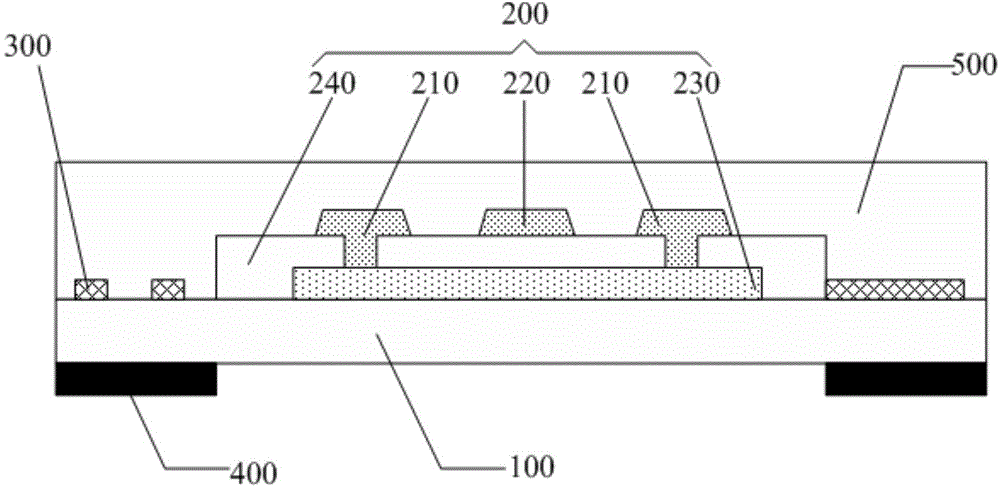

[0051] Specifically, in production such as image 3 In the case of the touch screen shown in the figure, the pattern including the shielding layer 400 is first formed on one side of the base substrate 100, then the base substrate 100 is turned over, and then peripheral wiring including electrical connections is formed on the other side of the base substrate 100 300 and the pattern of the touch control structure 200, wherein the touch control structure 200 includes touch sensing electrodes 210 and touch driving electrodes 220 arranged in the same layer, intersecting and insulated from each other, bridging the bridge between adjacent touch sensing electrodes 210 layer 230; and an insulating layer 240 between the bridging layer 230 and the touch sensing electrodes 210 and touch driving electrodes 220 arranged on the same layer; the touch screen manufacturing process, such as Figure 4 As shown, specifically, the following steps may be included:

[0052] S401, forming a pattern i...

example 2

[0067] in production as image 3 In the case of the touch screen shown in the figure, a pattern including electrically connected peripheral traces 300 and the touch structure 200 is first formed on one side of the base substrate 100, then the base substrate 100 is turned over, and then the other side of the base substrate 100 Forming a pattern including a shielding layer 400, wherein the touch structure 200 includes touch sensing electrodes 210 and touch driving electrodes 220 arranged in the same layer, intersecting and insulated from each other, bridging the bridging layer of adjacent touch sensing electrodes 210 230; and an insulating layer 240 between the bridging layer 230 and the touch sensing electrodes 210 and touch driving electrodes 220 arranged on the same layer; the touch screen manufacturing process, such as Figure 5 As shown, specifically, the following steps may be included:

[0068] S501, forming a pattern including an anti-reflection layer 600 on one side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com