Patterned preparation method of nano material field emission cathode

A field emission and patterning technology, used in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of poor vacuum environment, vacuum discharge or breakdown, affecting device stability, etc. Improve stability, reduce heat generation, and reduce the effect of interception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The present invention is specifically described below through the embodiment, only for further explanation of the present invention, can not be interpreted as the limitation of protection scope of the present invention, the technical engineer of this field can make some unessential to the present invention according to the content of above-mentioned invention improvements and adjustments.

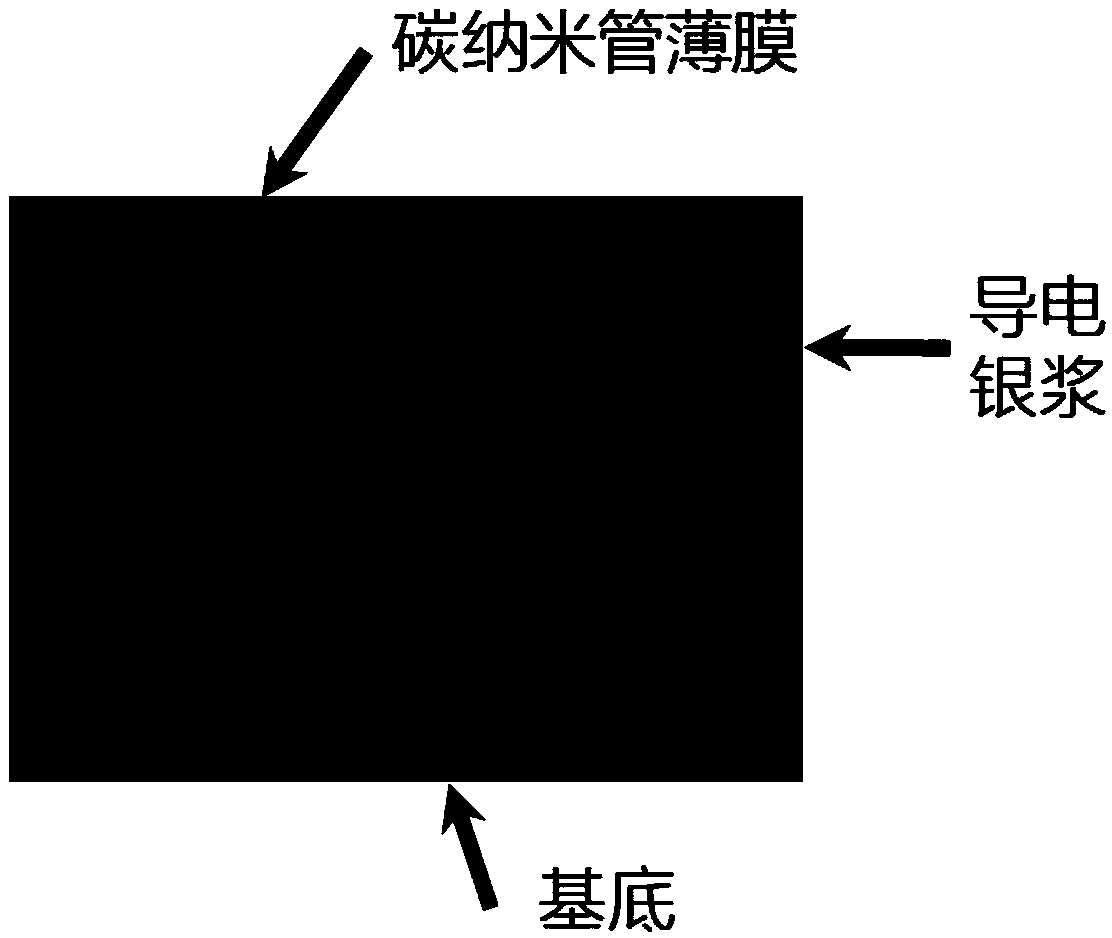

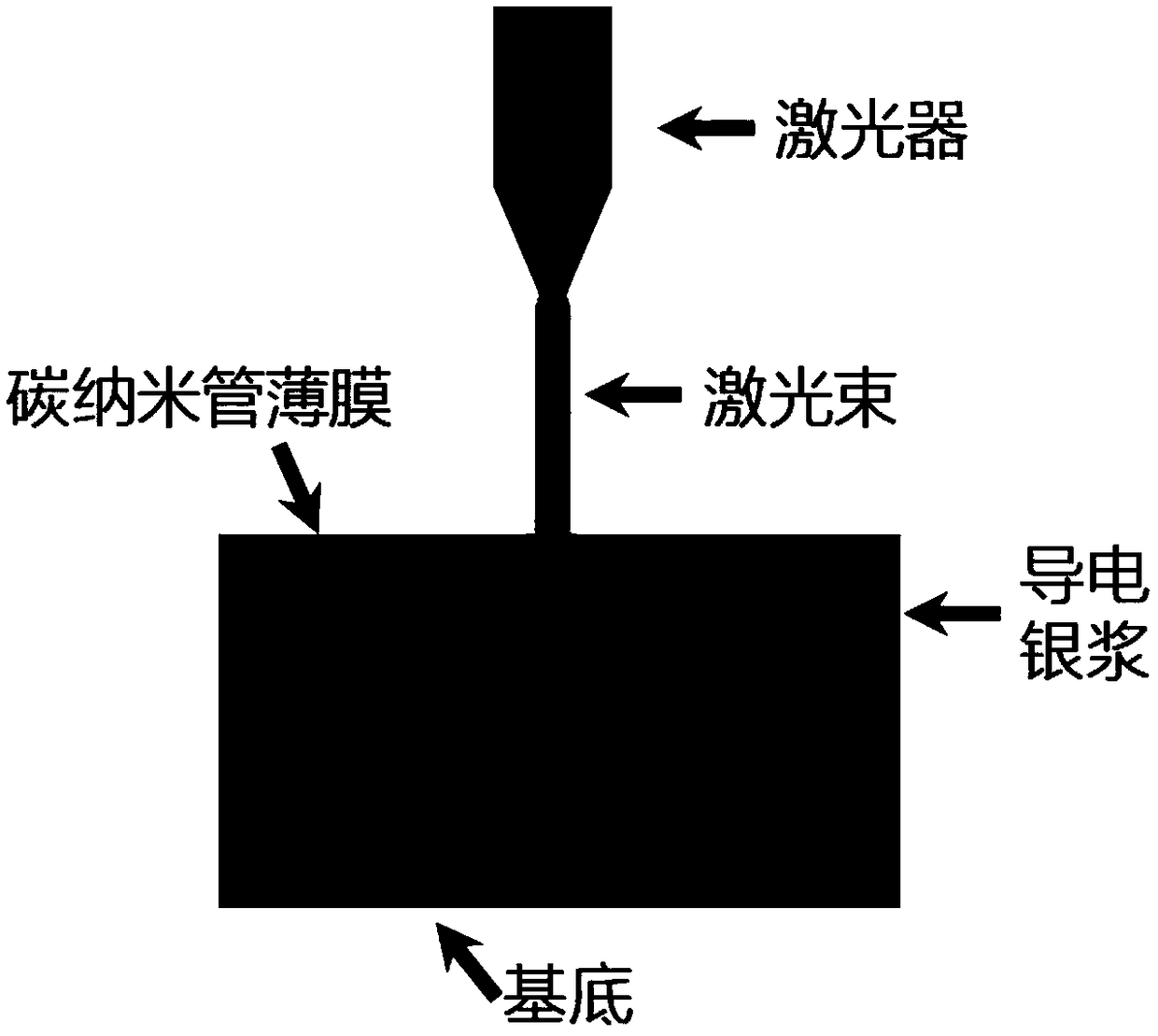

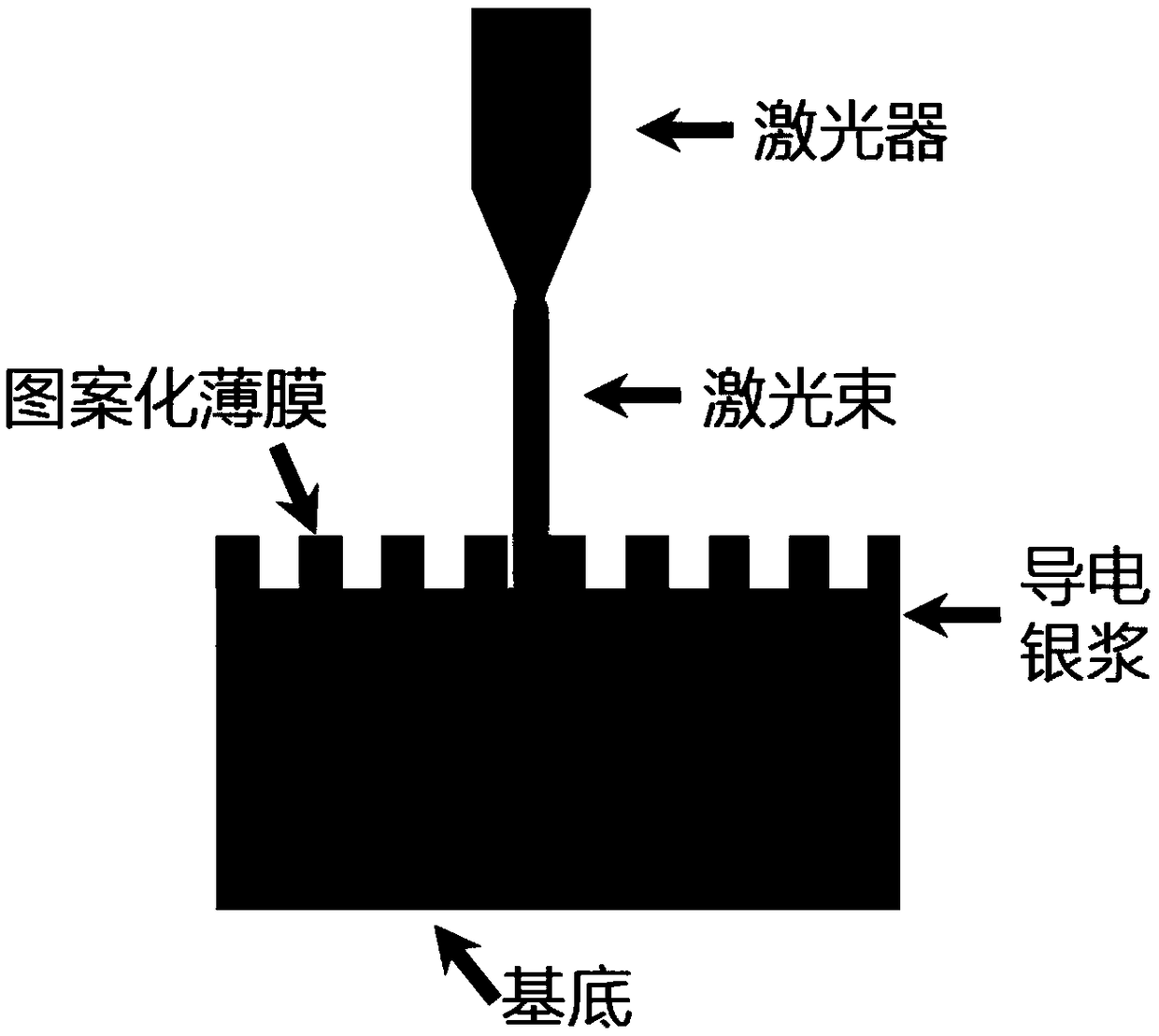

[0018] Such as figure 1 As shown, in this embodiment, the carbon nanotube field emission cold cathode based on the screen printing process is taken as an example, but it is not limited to the field emission cold cathode prepared in this way, and can also be obtained by vapor deposition, physical deposition, electrophoresis, etc. Cold cathode materials prepared by other methods. The material of the field emission cathode can also be films in the form of carbon nanotubes, graphene, zinc oxide, and nano-gap. In this embodiment, the specific implementation process is to prepare a carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com