Reverse osmosis membrane cleaner, cleaning solution, and cleaning method

A technology of reverse osmosis membrane and cleaning agent, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., to achieve effective cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

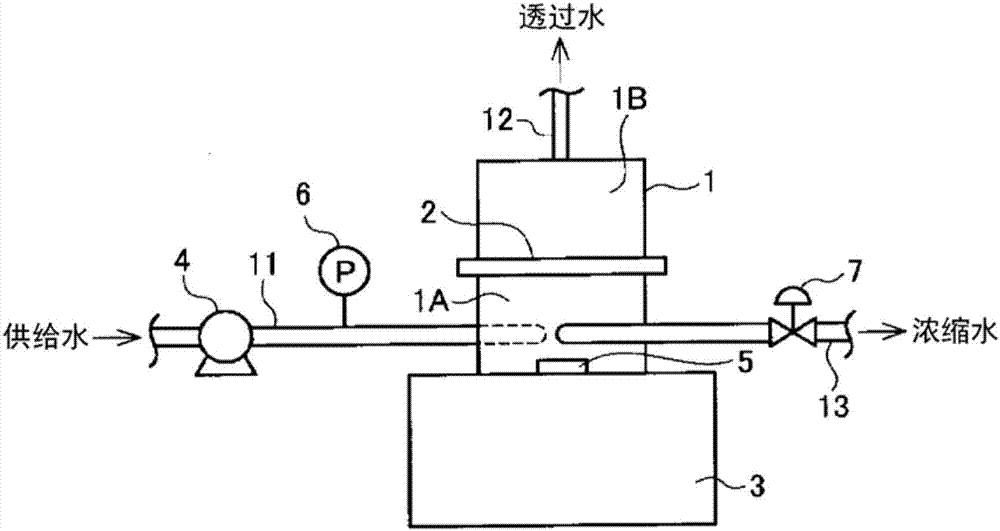

Method used

Image

Examples

Embodiment

[0100] Examples and comparative examples are given below to describe the present invention more specifically.

[0101] Among the reagents used in the following experiments I-IV, sodium chloride, sodium metasilicate 9 hydrate (for silica solution preparation), hydrochloric acid, isopropanol (IPA), various amino acids, hydroxide The sodium was all from Wako Pure Chemical Industries. Aspartame was from Ajinomoto Health Supply. ε-polylysine (molecular weight 4000-5000) was from JNC Company.

[0102] Sodium dodecylbenzenesulfonate was from Wako Pure Chemical Industries. Monochlorosulfamic acid was synthesized by using sulfamic acid (Wako Pure Chemical Industries, Ltd.), sodium hypochlorite (Asahi Glass Co., Ltd.), and sodium hydroxide by the method described in the section .

[0103] In the following experiments, it is preferable to suppress the increase of the flux of pure water without reducing the rejection rate in the immersion experiment of the cleaning solution. That is, ...

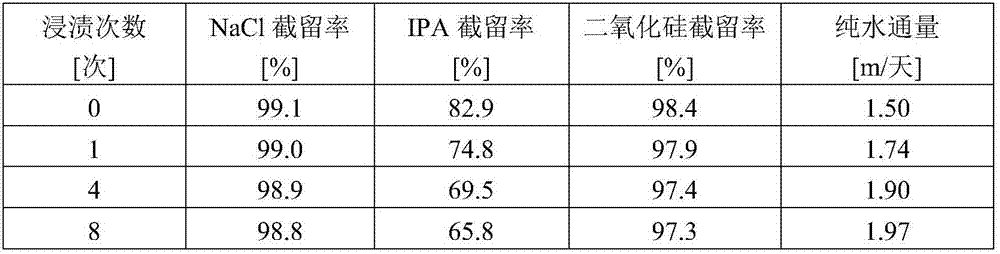

Embodiment I-1

[0136] The cleaning agent (4) was diluted 10 times with pure water to prepare a sodium hydroxide aqueous solution containing 2% by weight of arginine at pH 12, which was used as a cleaning solution, and the above experiment was carried out.

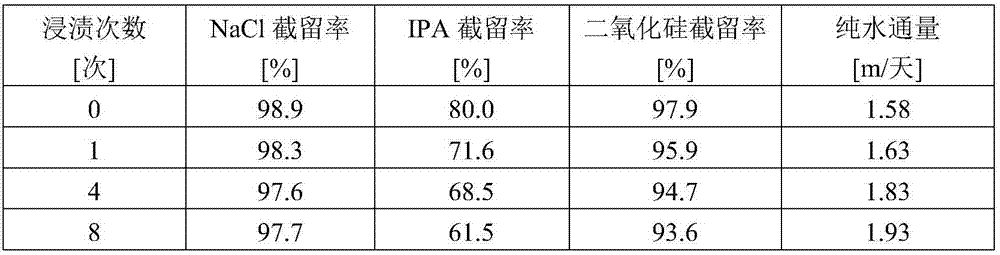

Embodiment I-2

[0138] The cleaning agent (5) was diluted 10 times with pure water to prepare an aqueous sodium hydroxide solution containing 2% by weight of aspartame at pH 12, which was used as a cleaning solution, and the above experiment was carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com