Method for covering thin film in hole and semiconductor processing apparatus

A technology for covering thin films and processing equipment, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems that TSV cannot achieve step coverage, reduce TSV step coverage, reduce film coverage, etc., and achieve the running direction. It is easier to control, take into account the production capacity, and reduce the effect of bombardment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order for those skilled in the art to better understand the technical solution of the present invention, the method for covering a film in a hole and the semiconductor processing equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

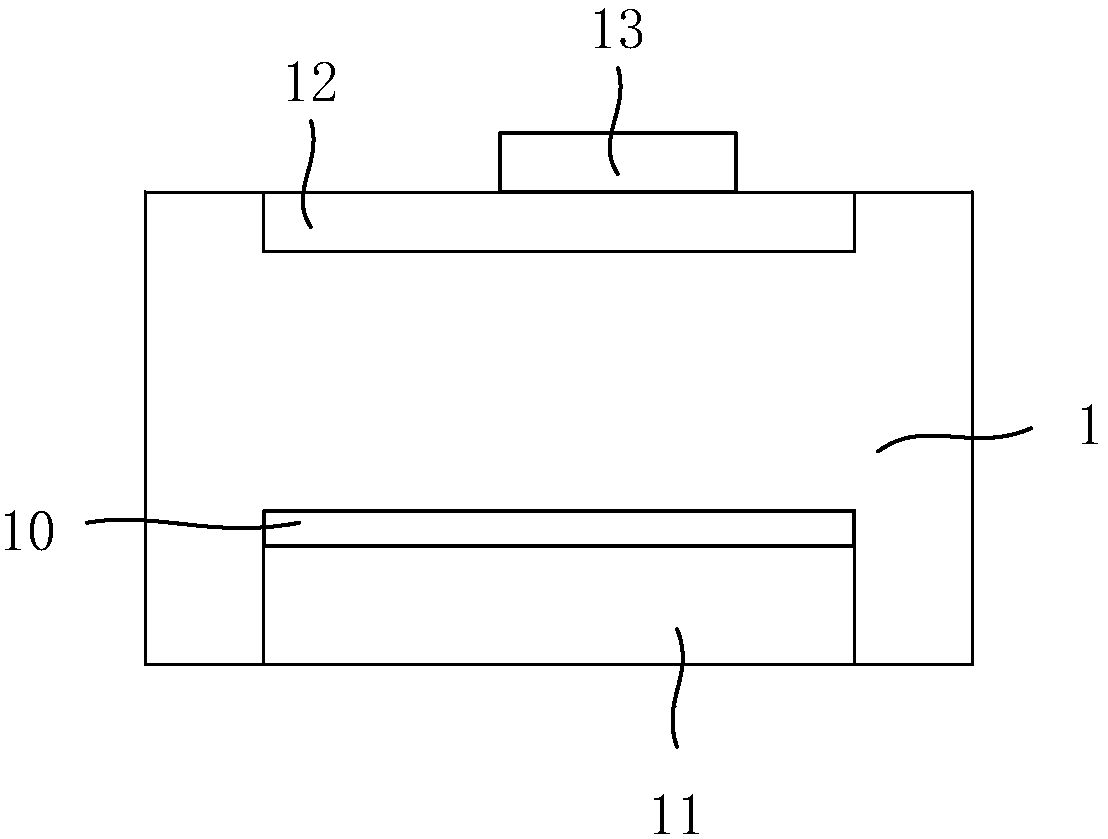

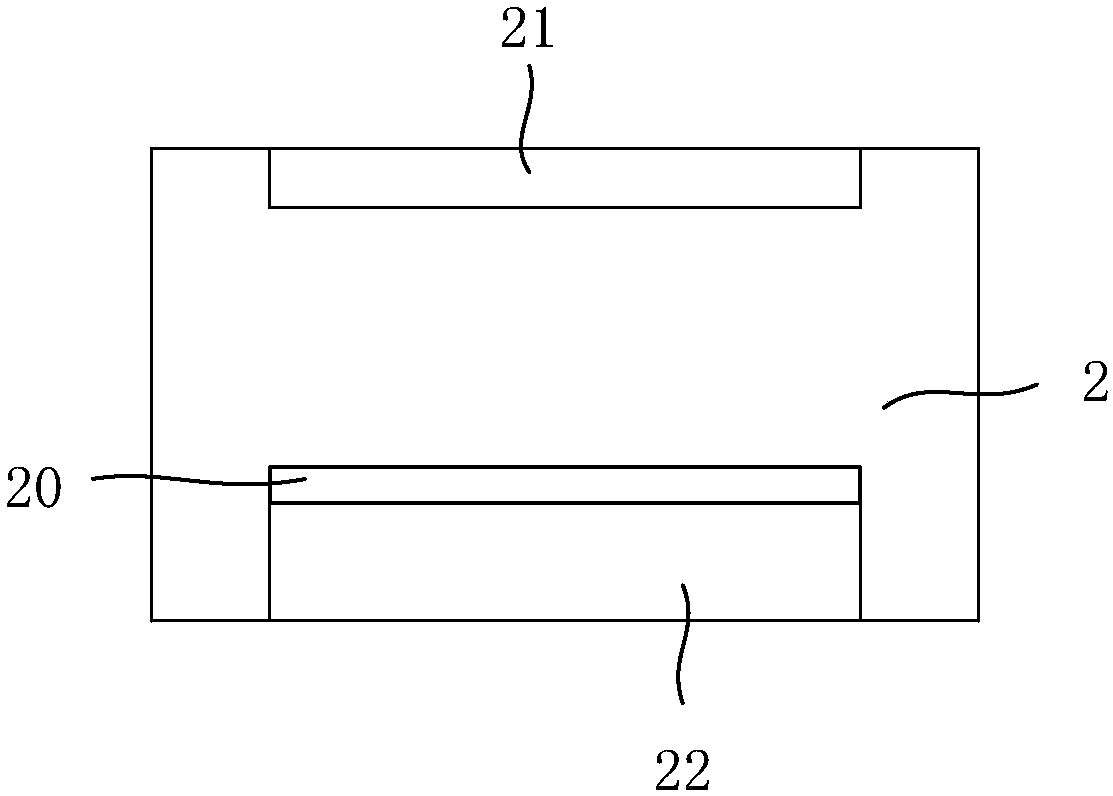

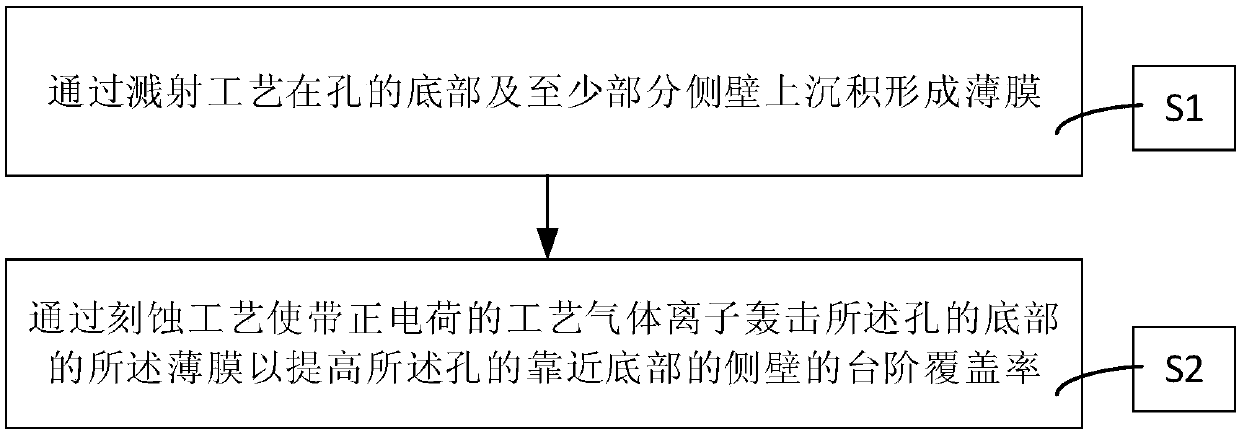

[0035] The semiconductor processing equipment provided by the present invention comprises a first chamber and a second chamber, the first chamber carries out a sputtering process, that is, the target metal ions obtained by the sputtering process in the first chamber, and the target metal ions Deposit and form a film on the bottom of the hole and at least part of the sidewall; the second chamber performs the reverse sputtering process, that is, the process gas is ionized in the second chamber, and the positively charged process gas ions are accelerated in the electric field The film is bombarded at the bottom of the well to increase the sidewall of the well near the bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com