High-working-ratio nano material cold cathode electron gun

A technology of nanomaterials and cold cathodes, applied in cathode ray tubes/electron beam tubes, nanotechnology, nanotechnology, etc., can solve problems such as limiting the application of nanomaterial cold cathode electron guns, restricting the development of fast-starting electronic systems, and electron bombardment. Achieve the effect of solving the burning problem, simple structure and promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

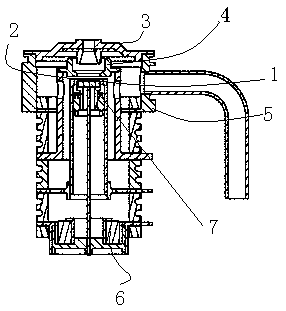

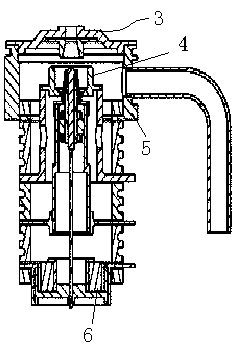

[0021] see figure 1 , Embodiment 1 of the present invention provides a technical solution: a high duty ratio nanomaterial cold cathode electron gun, the shadow grid is arranged on the cold cathode emission surface, the two are at the same potential, the shadow grid is a planar spoke grid, The planar cathode and the planar spoke grid are packaged on the cold cathode support assembly in sequence, the planar spoke grid is close to the cold cathode emission surface, shielding part of the cold cathode emission area, and laser spot welding is used between it and the cold cathode support of the cold cathode support assembly welding.

[0022] The control grid is also a planar spoke control grid, and the control grid is packaged on the cold cathode support assembly, and the control grid and the shadow grid plane spoke grid are grid-matched, and then the control grid is connected between the control grid and the control grid support of the cold cathode support assembly. Laser spot weld...

Embodiment 2

[0024] In the cold cathode electron gun described in Embodiment 2, the shadow grid is etched on the substrate, and nanomaterials capable of emitting electrons are arranged in the grid of the shadow grid; a mask is attached to a substrate such as silicon, and the concave hole is etched. Groove, form a grid, clean and remove the mask; attach iron and other catalysts required for the growth of nanomaterials on the substrate; physically polish the substrate to remove the catalyst on the substrate grid; grow nanomaterials on the substrate to obtain a shadow grid cold cathode ; Next, except that the shadow grid is no longer assembled, the others are the same as the first embodiment.

Embodiment 3

[0026] In the cold-cathode electron gun described in the third embodiment, the shadow grid and the control grid are conical pillar grids, and the others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com