Tectorial bracket

A covered stent and film-covered technology, applied in stents, medical science, blood vessels, etc., can solve problems such as injury and vascular injury, and achieve the effect of firm structure, good support, and prevention of displacement or shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

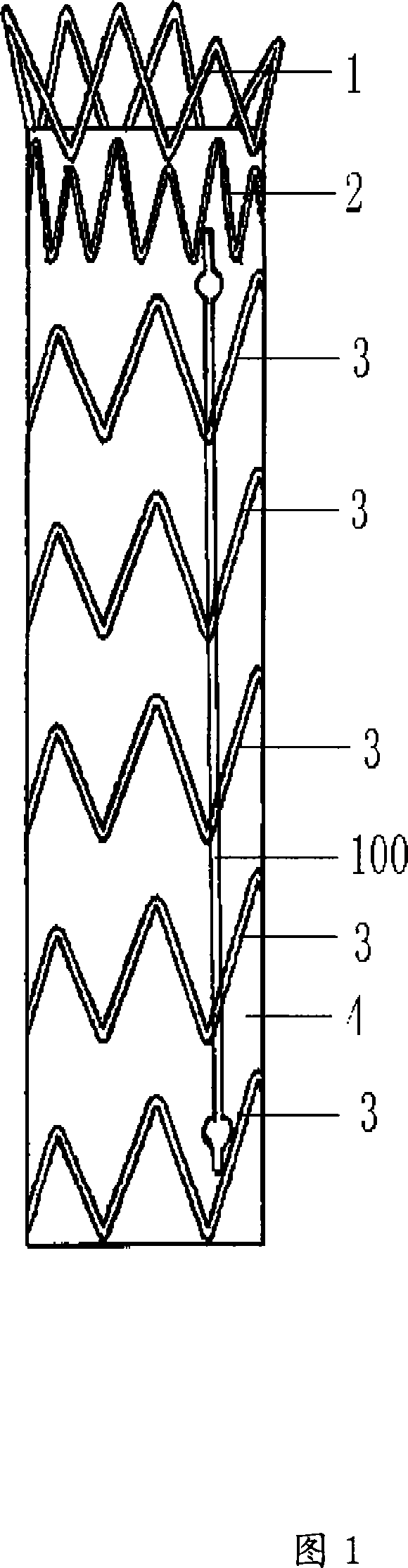

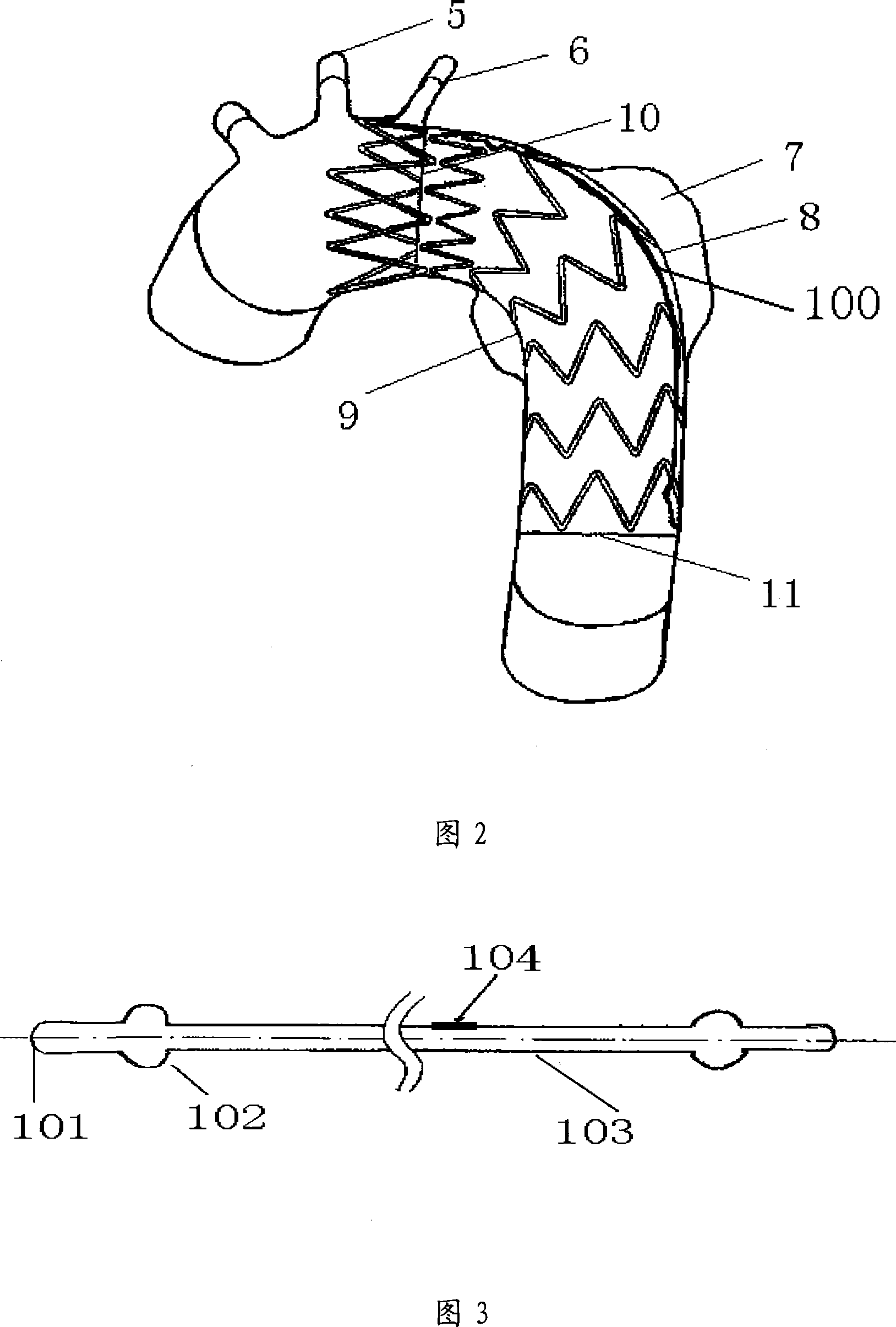

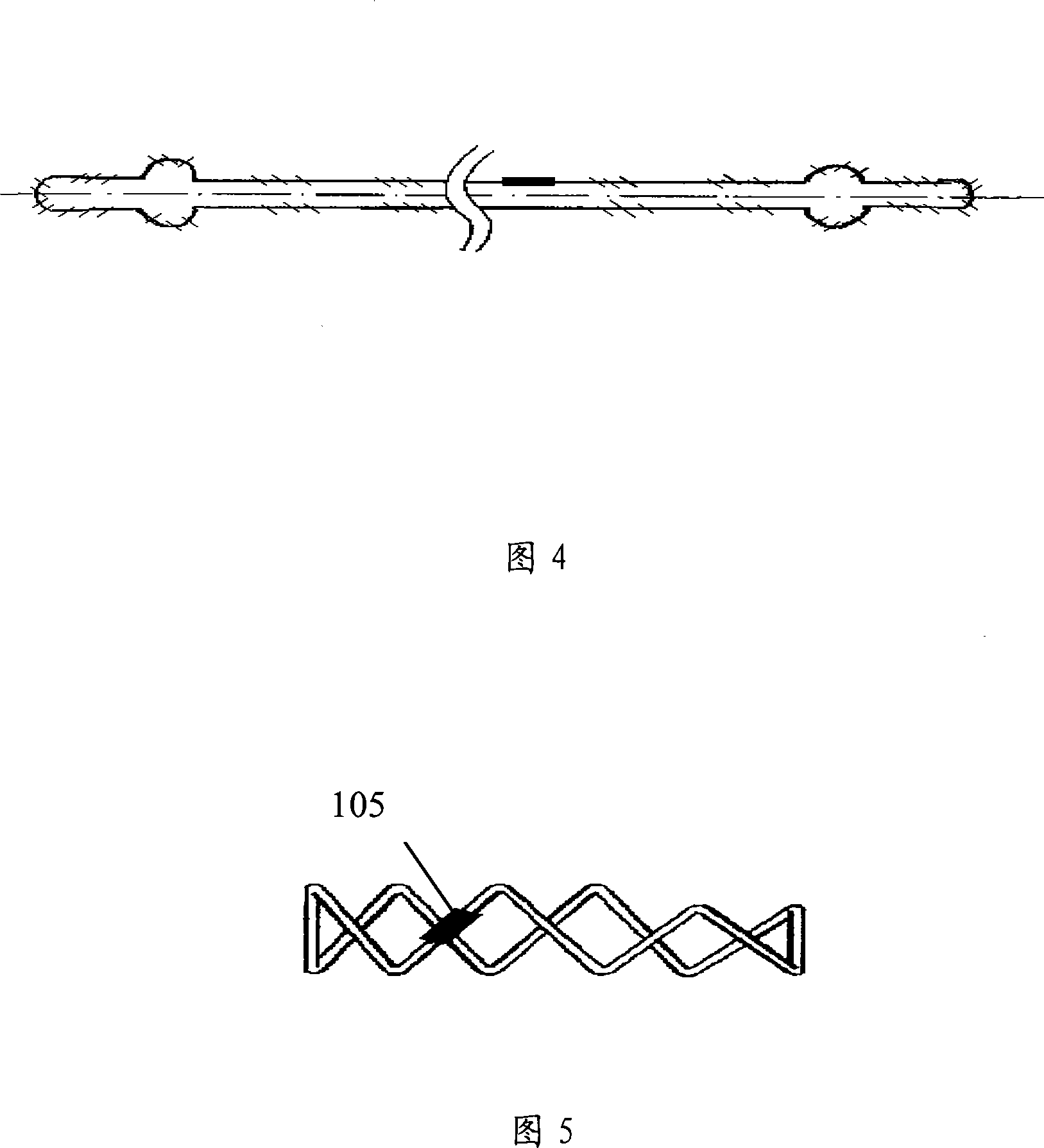

[0034] The present invention will be further described below in conjunction with the accompanying drawings. In the stent-graft shown in FIG. 1 , the length of the covering 4 is 120 mm, the diameter of the covering tube is 28 mm, and the length of the reinforcing rib 100 is 110 mm. The alloy wire used in the reinforcing rib 100 shown in FIG. 3 is a nickel-titanium wire with a diameter of 0.016 inches, and the reinforcing rib connector 104 is a nickel-titanium tube with an inner diameter of 0.017 inches. The two ends of the reinforcing rib nickel-titanium wire are connected with the nickel-titanium by laser welding technology. The pipe is welded and fixed, the head end 101 of the reinforcing rib is designed in an arc shape, the trunk sections 103 of the reinforcing rib are parallel to each other, and the reinforcing rib has a fixed ring 102 structure near both ends.

[0035] The structural design of the stent-graft implemented in the present invention can be determined according...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com