Double-sided cooling annular fuel rod with wrapping wire

A technology of double-sided cooling and fuel rods, which is applied in the field of nuclear power to achieve the effects of improving DNBR, reducing flow resistance, and enhancing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

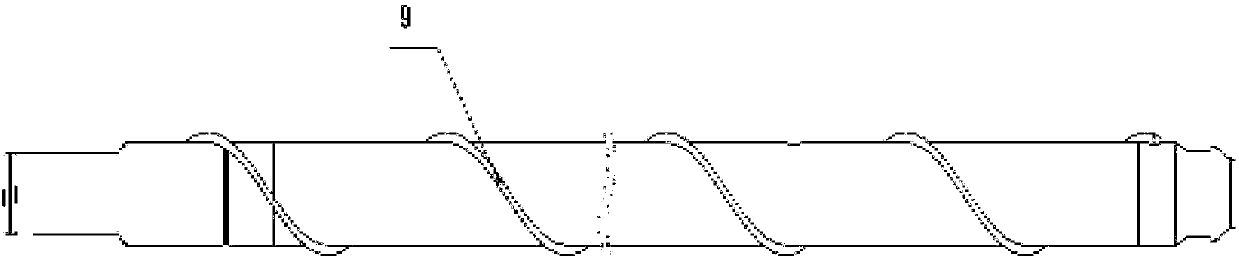

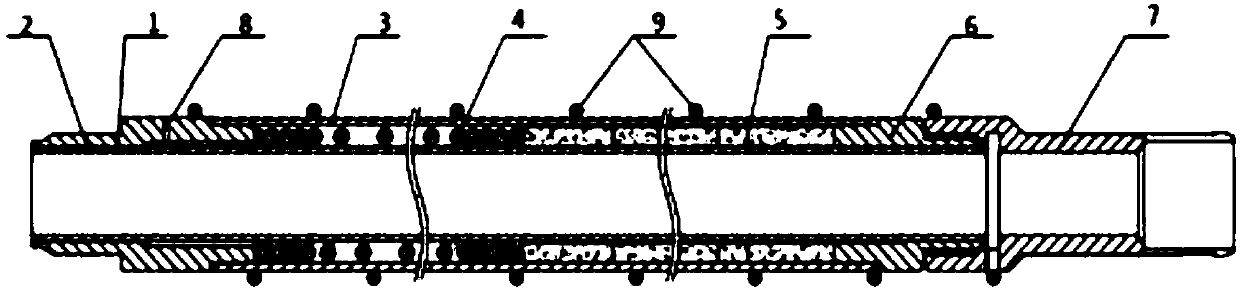

[0032] Such as figure 1 with figure 2 As shown, a double-sided cooling annular fuel rod with wire wrapping described in the present invention includes an upper end plug 1, a lower end plug 6, an inner cladding 2, an outer cladding 3, and an annular fuel pellet 5; wherein , the cavity formed by nesting the inner cladding 2 and the outer cladding 3 is used to accommodate the annular fuel pellet 5, the upper end of the inner cladding 2 and the outer cladding 3 are connected to the upper end plug 1, and the lower end is connected to the lower end plug 6;

[0033] A winding wire 9 is wound on the outer surface of the outer casing 3 , that is, the winding wire 9 is spirally wound on the outer surface of the outer casing 3 . One end of the winding wire 9 is fixed on the lower end plug 6 by welding; the other end is fixed on the upper end plug 1 by welding.

[0034] The upper or lower end plug 6 of the tubular fixing member 7 is provided with 2 to 6 side openings away from the weld...

Embodiment 2

[0040] Such as figure 1 with figure 2 As shown, a double-sided cooling annular fuel rod with wire wrapping described in the present invention includes an upper end plug 1, a lower end plug 6, an inner cladding 2, an outer cladding 3, and an annular fuel pellet 5; wherein , the cavity formed by nesting the inner cladding 2 and the outer cladding 3 is used to accommodate the annular fuel pellet 5, the upper end of the inner cladding 2 and the outer cladding 3 are connected to the upper end plug 1, and the lower end is connected to the lower end plug 6;

[0041] Three winding wires 9 are wound on the outer surface of the outer casing 3 , that is, the winding wires 9 are spirally wound on the outer surface of the outer casing 3 . One end of the winding wire 9 is fixed on the lower end plug 6 by welding; the other end is fixed on the upper end plug 1 by welding.

[0042] The lower end plug 6 of the annular fuel rod is fixed on the lower tube seat through a tubular fixing member 7 ...

Embodiment 3

[0050] Such as figure 1 with figure 2 As shown, a double-sided cooling annular fuel rod with wire wrapping described in the present invention includes an upper end plug 1, a lower end plug 6, an inner cladding 2, an outer cladding 3, and an annular fuel pellet 5; wherein , the cavity formed by nesting the inner cladding 2 and the outer cladding 3 is used to accommodate the annular fuel pellet 5, the upper end of the inner cladding 2 and the outer cladding 3 are connected to the upper end plug 1, and the lower end is connected to the lower end plug 6;

[0051] Three winding wires 9 are wound on the outer surface of the outer casing 3, that is, the winding wires 9 are spirally wound on the outer surface of the outer casing 3: one end of the winding wire 9 is fixed on the lower end plug 6 by welding; It is fixed on the upper end plug 1 by welding.

[0052] The ratio of the pitch of the winding wire to the length of the annular fuel rod is 1:8. The material of the winding wire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com