Molten metal filtering device

A filtration device and technology for molten metal, applied in filtration separation, metal processing equipment, separation methods, etc., to achieve the effect of avoiding filter breakage and good filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

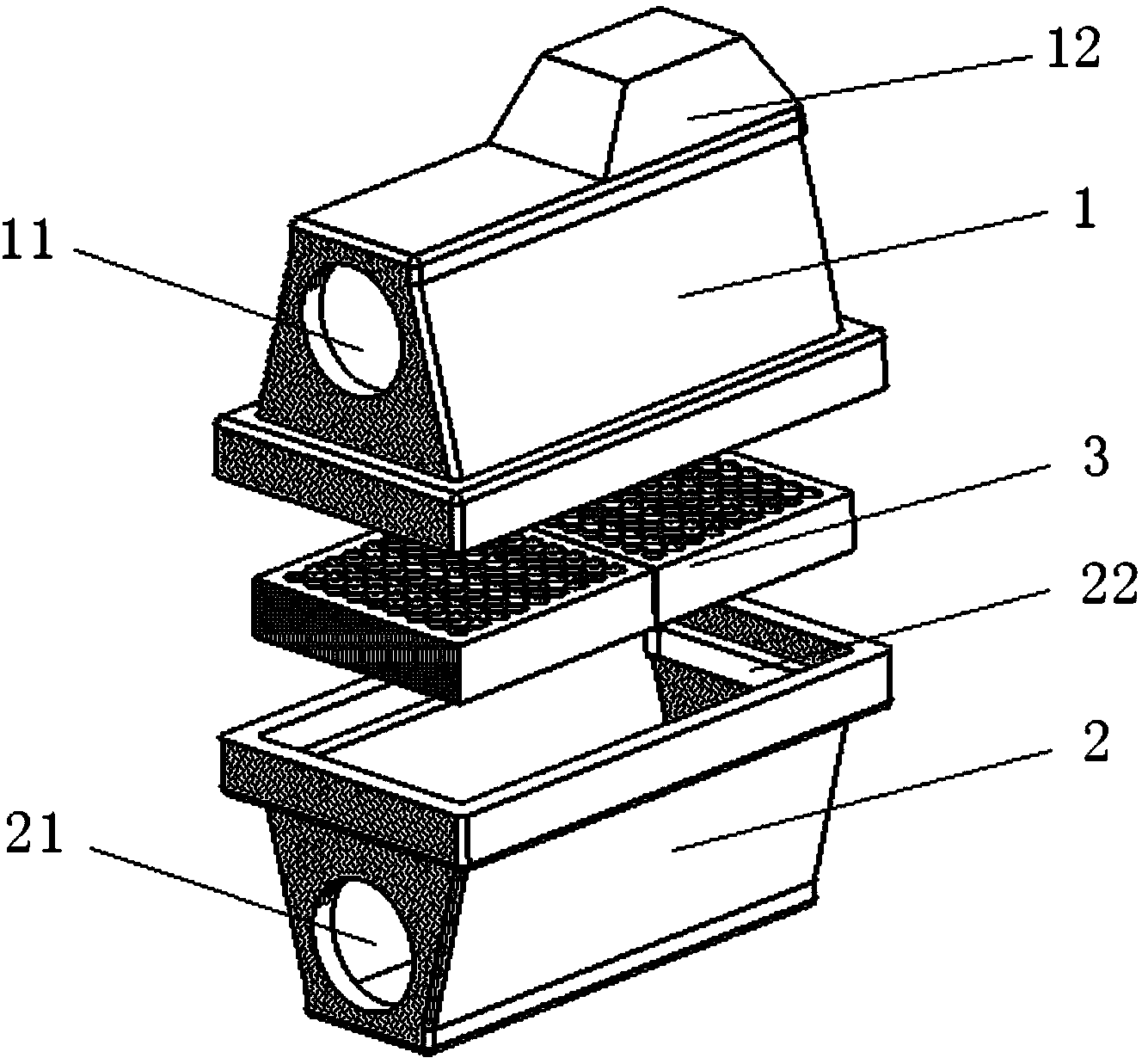

Image

Examples

Embodiment 1

[0046] Use 20% of alumina, 30% of bauxite, 40% of burnt gemstone and 10% of clay as raw materials, add 3 times of water, mix evenly by ball milling for 1 hour, use grouting molding, inject ceramic slurry into the prefabricated mold, and filter in the mold The size of the support part of the device is 200*600, the liquid inlet and outlet chambers are formed separately, dried at 60°C for 3 hours, and fired at 1300°C for 3 hours; then put three pieces of 200*200*30*(10ppi) zirconia Into the support part, combined into a filter device, the test proved that the filter device can filter 4t molten steel or 8t molten iron.

Embodiment 2

[0048] Use an intermittent high-speed sand mixer, add 88% quartz sand (70 / 140 mesh in particle size) and 12% water glass into the sand mixer, mix for 280s, and produce sand; adjust the sand shooting pressure of the sand shooting machine to 0.3MPa, and the sand shooting time 3s; blowing carbon dioxide after sand shooting, blowing pressure 0.2MPa, blowing time 2s; demoulding after blowing.

[0049] Make a filter device with a filter support surface of 900*150 according to the above process, place 6 pieces of carbon filters 150*150*30 (10ppi), a single filter device can filter 4t stainless steel, gray iron 8t, combined use can double the increase filtering ability.

Embodiment 3

[0051] The coated sand with a particle size of 70 / 140 mesh is used, and the equipment is a coated sand blasting machine. The heating temperature is 200°C, the curing time is 150s, the sanding pressure is 0.3MPa, the sanding time is 5s, and the shelling time is 50s before demoulding. Make a filter device with a support surface of 200*600, place 3 zirconium filters 200*200*30 (10ppi), a single filter device can filter 2 tons of stainless steel, and 4 tons of ductile iron, and the combined use can increase the filtering capacity doubled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com