Device for supporting articles to be fired that has a defined compensation of thermal expansions

A technology for products and the like, which is applied in the field of devices for determining and compensating thermal expansion of objects to be burned, can solve the problems of reducing and maintaining high friction, and achieves the effect of avoiding peak stress and reducing thermal expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

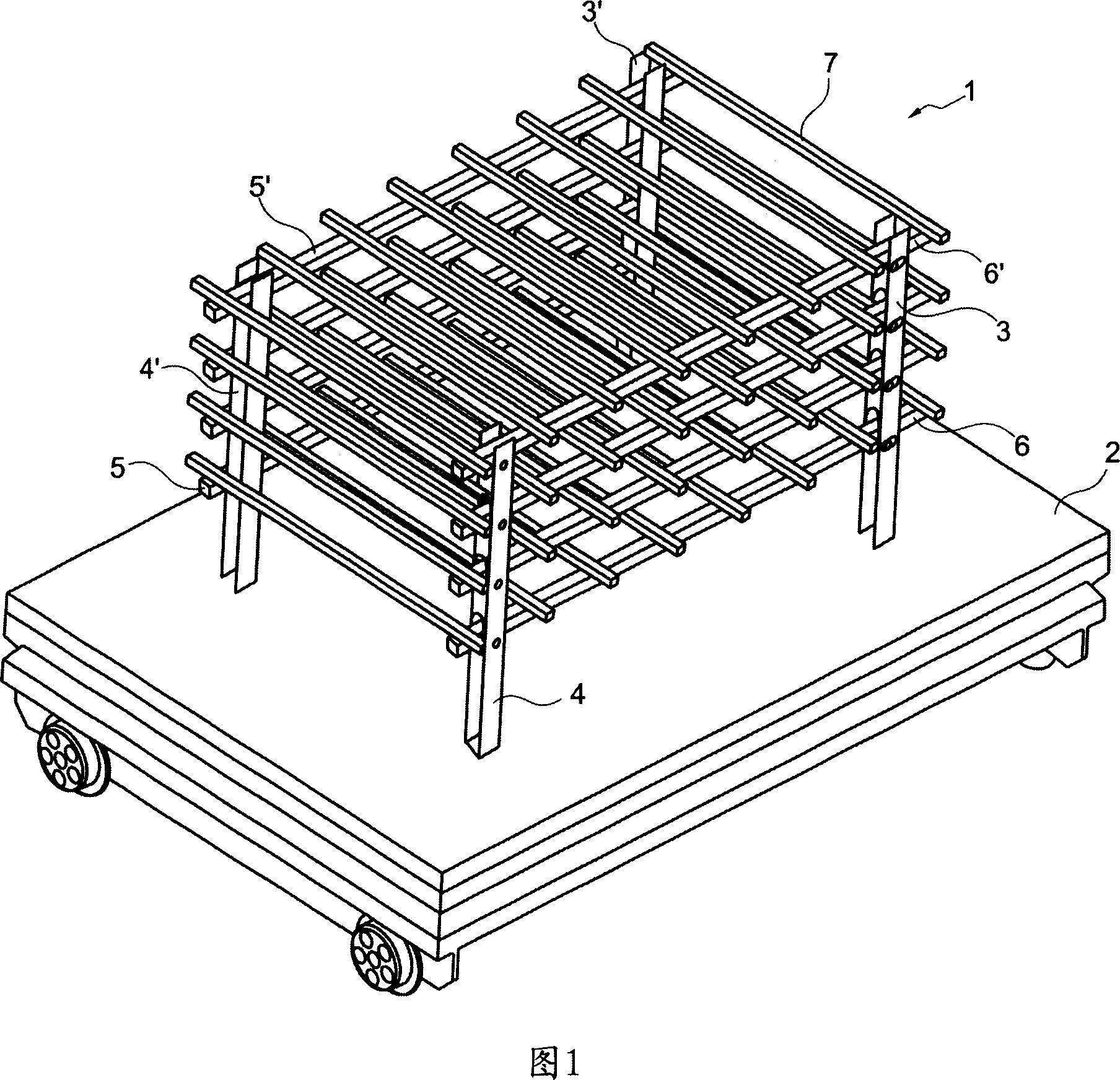

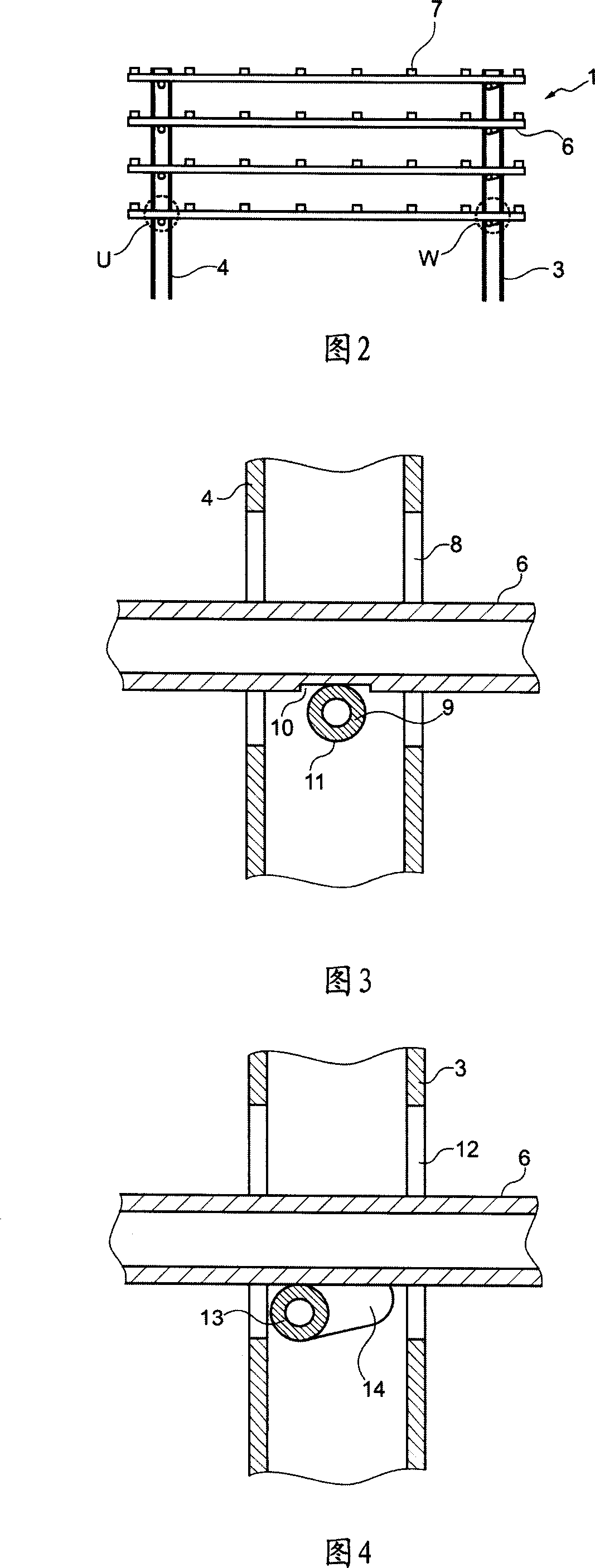

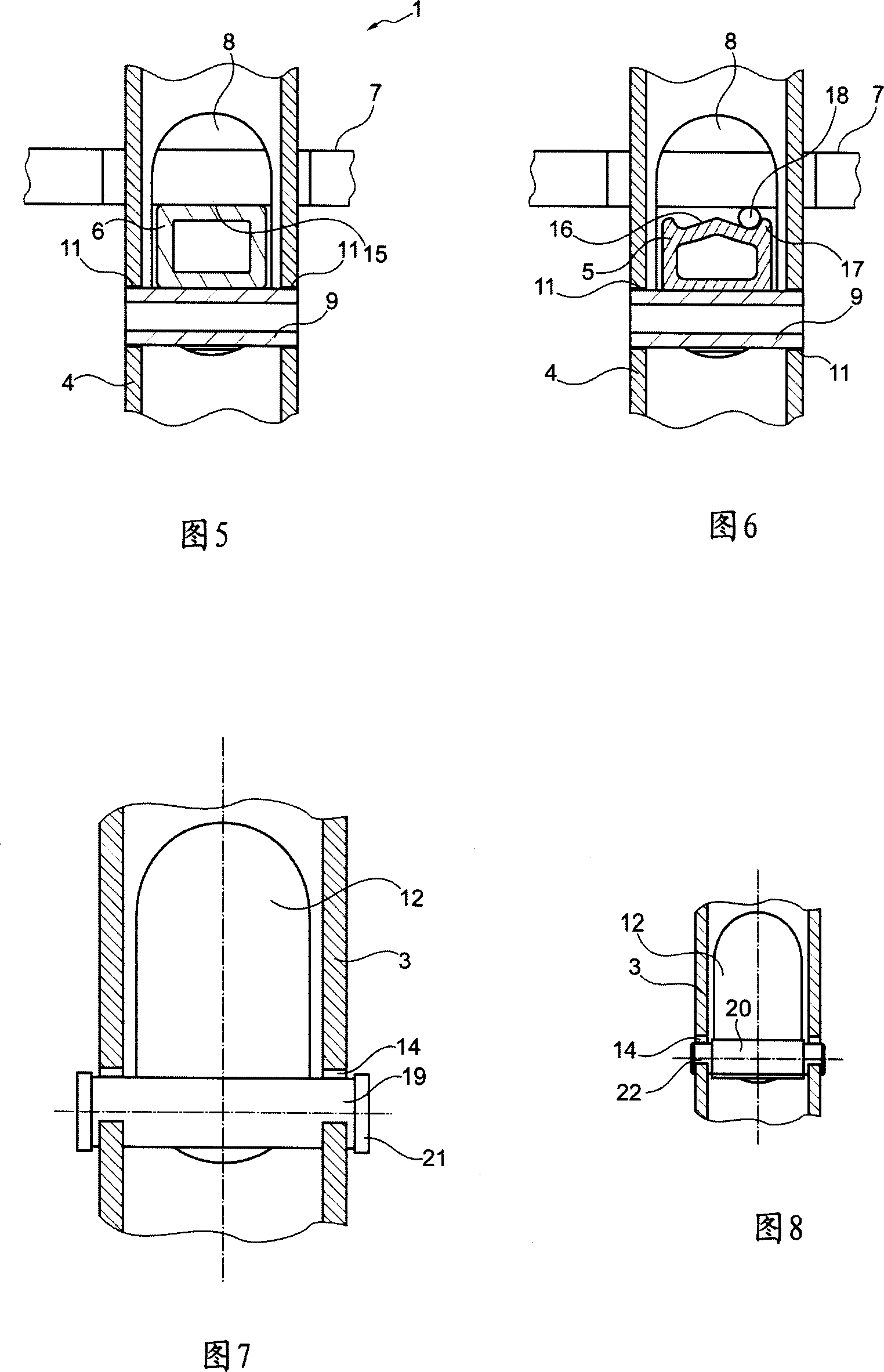

[0026] Figure 1 shows a precise schematic diagram of an embodiment of the device 1 of the invention for stacking and transporting kiln products mounted on a kiln car 2 of known type. Said device 1 of the invention comprises four vertical struts 3, 3', 4, 4' placed in a rectangular manner, each two of them 3, 4 and 3', 4' receiving and supporting a row of load-bearing beams 5, 5', 6, 6'. Thus, the specific load beams 5, 6, 5', 6' of the pair of columns 3, 4 and 3', 4' are placed in parallel horizontal planes. On such opposing pairs of load beams 5, 6 and 5', 6', a further row of beams 7 is placed, extending perpendicularly to the load beams 5, 5', 6, 6' and the struts 3, 3', 4, 4' . On the device 1 of the invention, kiln products, in particular pottery kiln products, can be supported, stacked and transported by kiln cars 2 . Such a kiln car 2 allows easy entry and exit of kiln products from the furnace, wherein these processes can also be automated by said kiln car. Further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com