Rope capable of avoiding breakage danger

A technology of breaking danger and ropes, which is applied in the direction of textiles, papermaking, textile cables, etc., can solve the problems of complicated length and bending of ropes, loss of cargo ships, and no obvious signs of wear and tear, so as to prevent rope breakage accidents, inspection convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

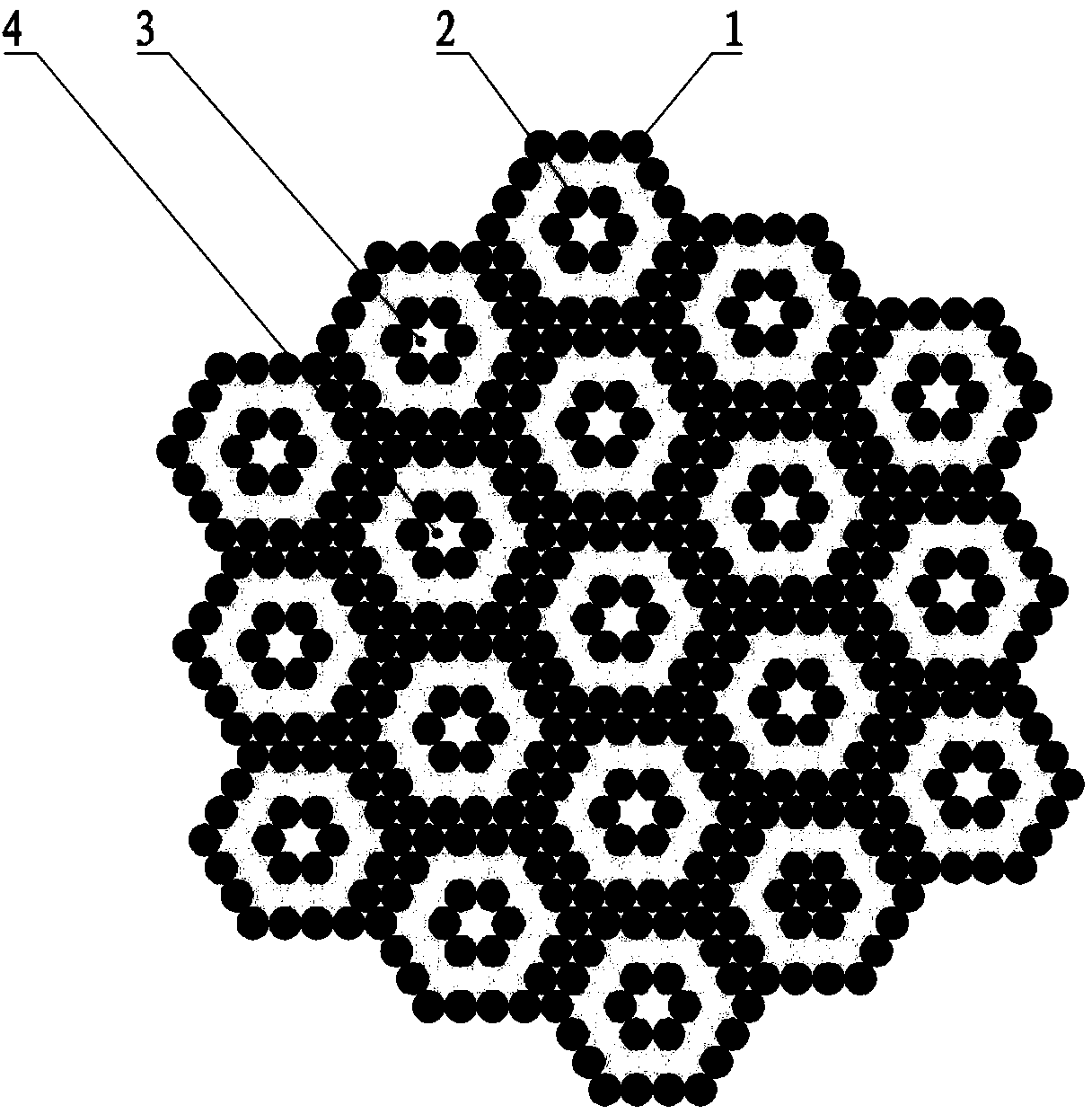

[0009] 1. If figure 1 As shown, a cable is twisted by nylon wire, totally 19 strands and 3 layers, and each strand has 37 monofilaments twisted in four layers of 1, 6, 12, and 18. Among them, 18 monofilaments are the cortex and the rest are the core layer. The cortex 1 nylon of 12 outer layers 3 is natural color, and the core layer 2 nylon is yellow. The cortex of the second of the 7-strand inner layers 4 is orange and the core is red.

[0010] 2. The rope in this example is made of monofilament twisted yarn made of hemp fiber. The outer layers are twisted according to the skin-core structure. The cortex is yellow and the core is red. The inner layers are the natural color of hemp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com