Flexible display device and making method thereof

A technology of a flexible display device and a manufacturing method, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of deformation limitation of flexible display substrates and reduction of deformation capacity of flexible display devices, and achieve the effect of preventing TFT characteristics from changing or breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

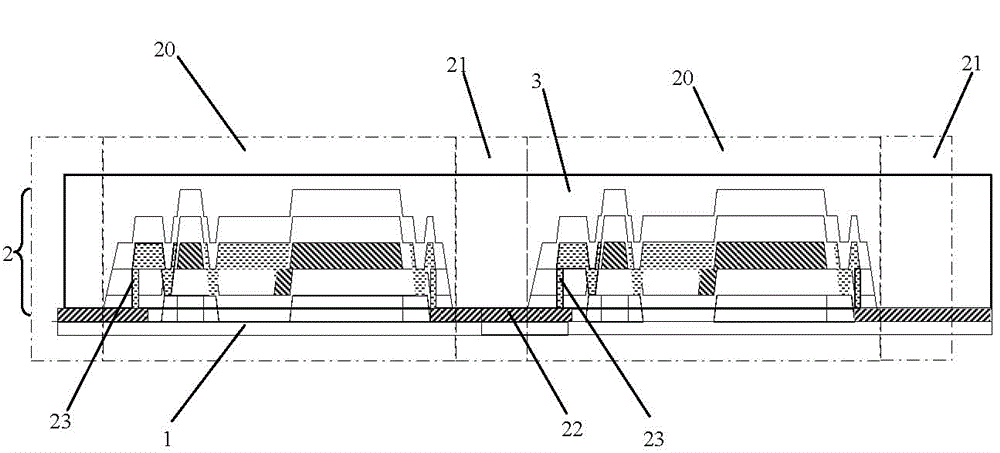

[0023] In order to facilitate a further understanding of the structure, method and achieved effects of the present invention, preferred embodiments are described in detail below in conjunction with the accompanying drawings.

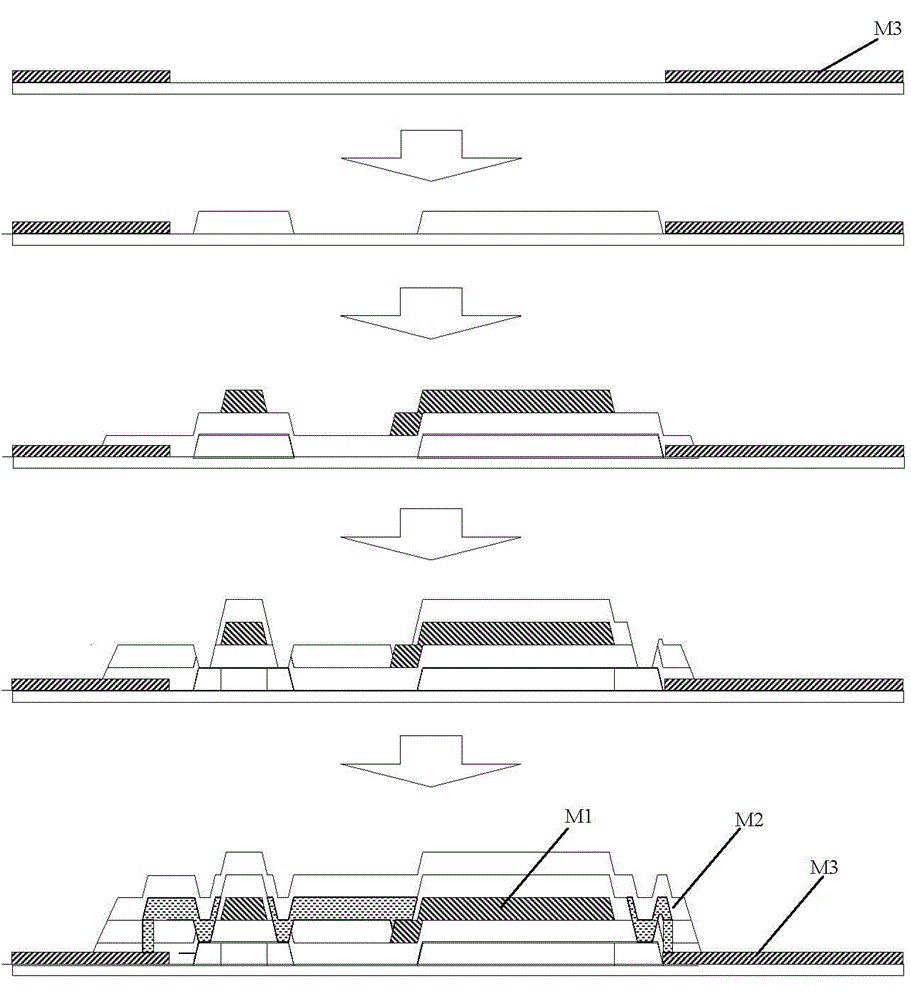

[0024] like figure 1 As shown, the manufacturing method of the flexible display device of the present invention includes the following steps:

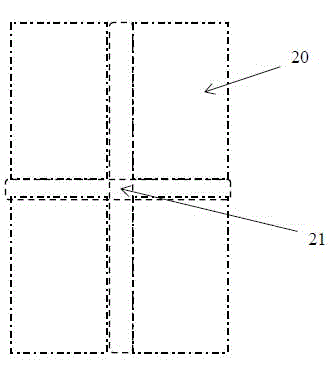

[0025] Step 1. First, divide the flexible substrate into a pixel area and a bending area, and the bending area is divided into multiple rows and columns of pixel areas in the form of rows and columns;

[0026] Step 2, making a metal connection layer M3 in the predetermined bending area (that is, between adjacent pixel areas) on the flexible substrate;

[0027] Step 3: Fabricate TFTs in the pixel area on the flexible substrate, and sequentially fabricate each layer structure of the TFTs;

[0028] Step 4. After the TFT is manufactured, a flattening layer is formed on the bending area between each pixel area and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com