Molybdenum-titanium lubricating oil composition and application thereof

A technology of lubricating oil composition and titanium compound, which is applied in the field of lubricating oil, can solve the problems of three-way catalytic converter poisoning, three-way catalyst poisoning, reducing the service life and effectiveness of catalytic converters, and achieve improved anti-wear and anti-oxidation Performance, anti-poisoning, anti-oxidation, thickening and foaming of engine oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

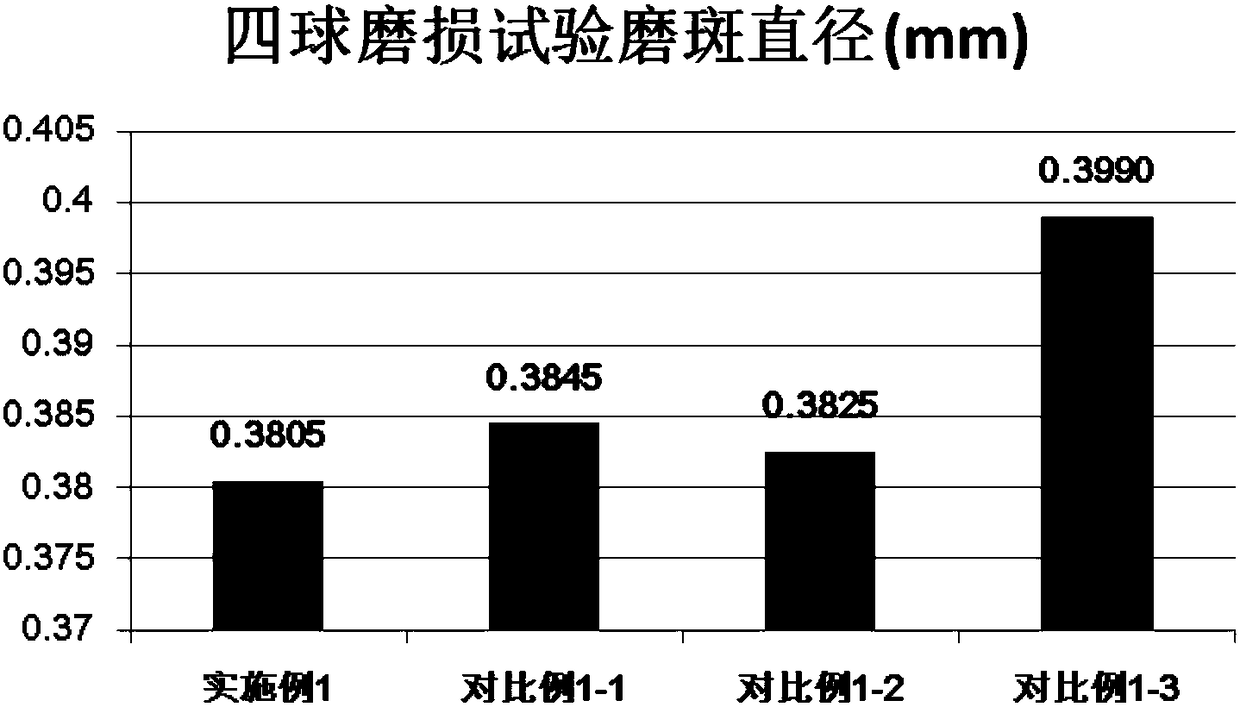

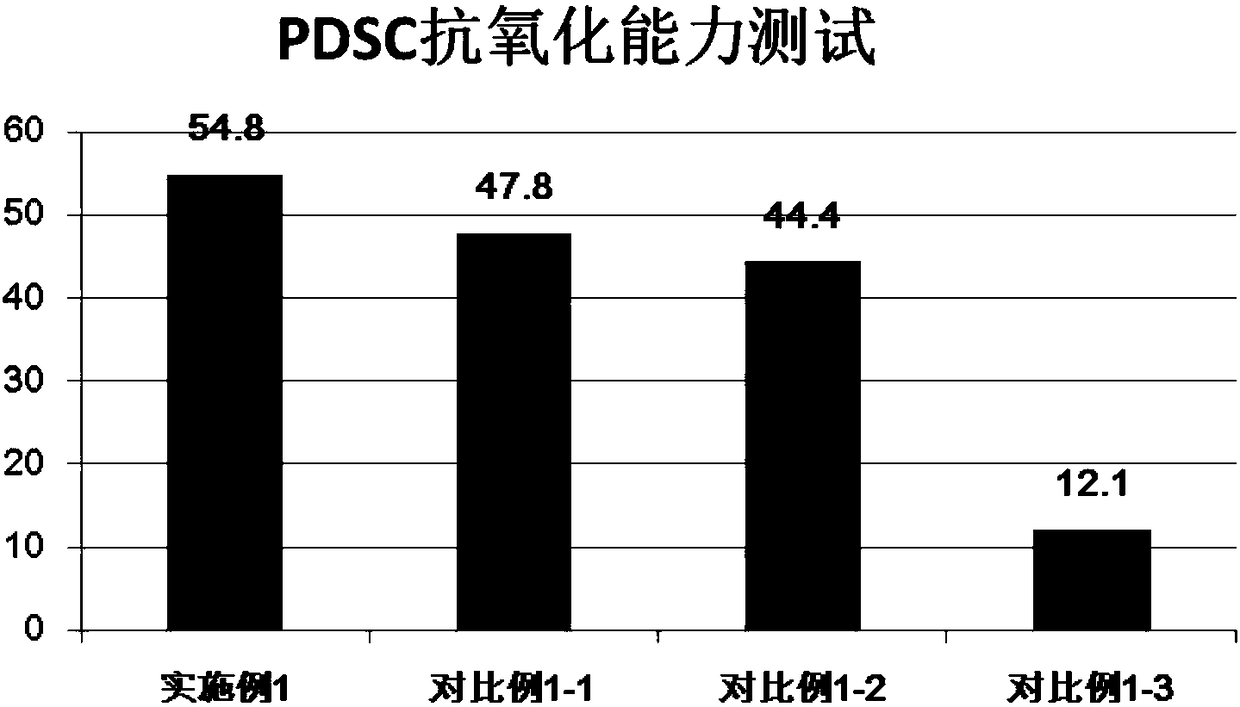

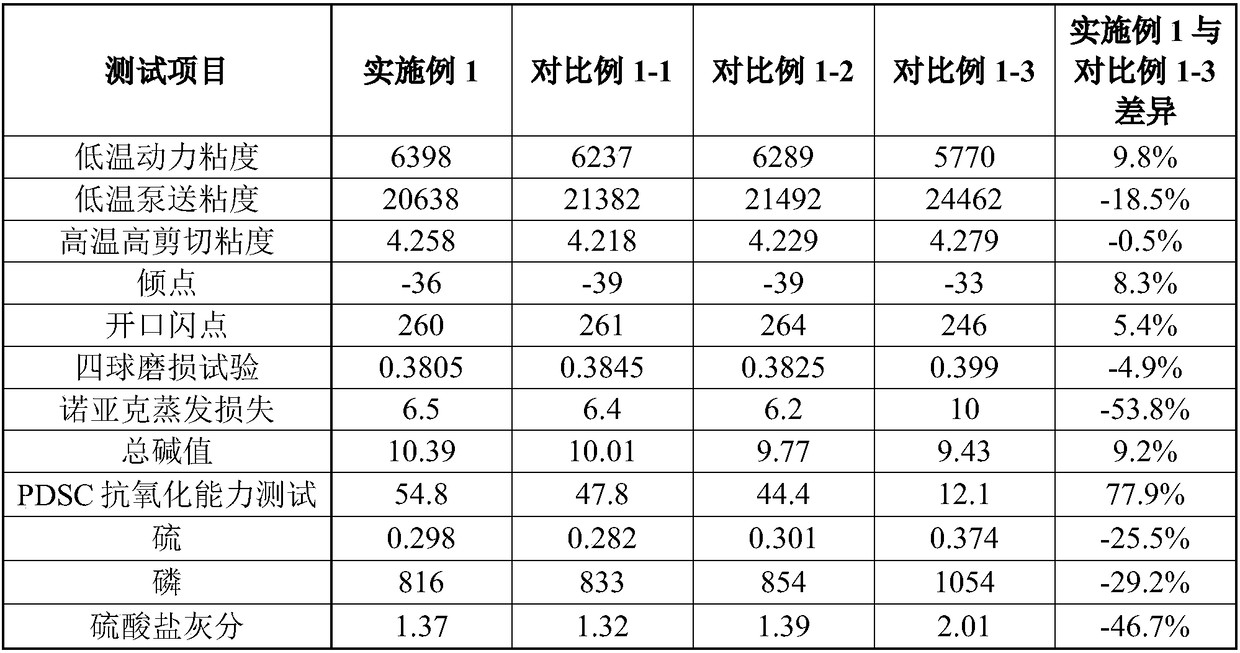

Embodiment 1

[0055] Add 8.25kg base oil, 0.0835kg tripoly molybdenum alkyl thiocarbamate salt, 0.05kg oil-soluble titanium compound, 0.016kg pour point depressant, 0.6kg viscosity finger agent, 1.0kg compound agent and 0.5mL antifoaming agent in turn Stir in a stirring vessel for 45 minutes, take a sample and observe, it is a molybdenum-titanium lubricating oil composition that is completely transparent.

Embodiment 2

[0057] Add 8kg base oil, 0.2kg trimeric molybdenum alkyl thiocarbamate salt, 0.0294kg oil-soluble titanium compound, 0.02kg pour point depressant, 0.45kg viscosity finger agent, 1.3kg compounding agent and 0.6mL antifoaming agent in turn and stir. Stir in the container for 45 minutes, take a sample and observe, it is a molybdenum-titanium lubricating oil composition that is completely transparent.

Embodiment 3

[0059] Add 8.85kg base oil, 0.1kg alkyl thiocarbamate tripoly molybdenum salt, 0.0392kg oil-soluble titanium compound, 0.01kg pour point depressant, 0.5kg viscosity finger agent, 0.5kg compounding agent and 0.8mL antifoaming agent in turn Stir in a stirring vessel for 45 minutes, take a sample and observe, it is a molybdenum-titanium lubricating oil composition that is completely transparent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com