Drive method of plasma display device

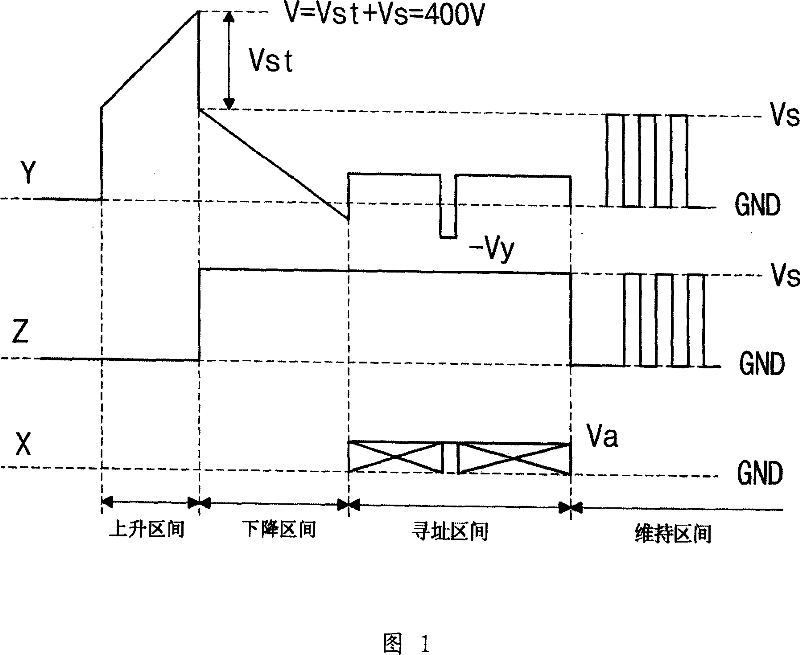

A technology of plasma display and driving method, which is applied to static indicators, instruments, identification devices, etc., and can solve problems such as poor discharge and deterioration of jitter characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

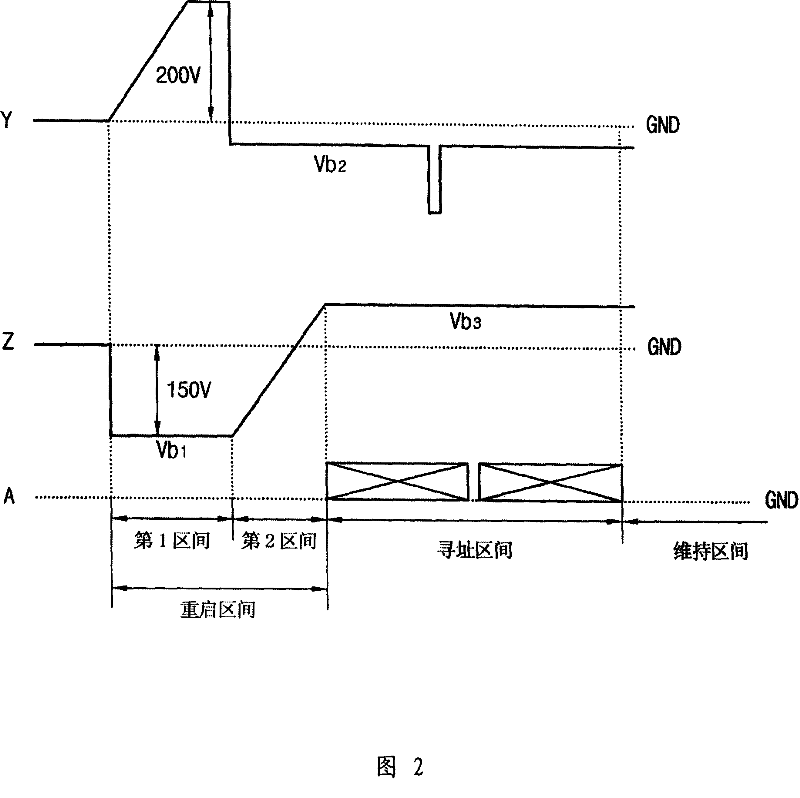

[0018] Fig. 2 is a waveform diagram of the driving of the plasma display of the present invention.

[0019] As shown in FIG. 2 , in the first interval of the reset interval, an up-ramp pulse with a specific slope higher than the ground voltage level is input to the Y electrode, and a negative first bias voltage (Vb1) is input to the Z electrode. At the same time, in the second interval of the reset interval, a negative second bias voltage (Vb2) is input to the Y electrode, and a third bias voltage is input to the Z electrode that is increased by a certain slope from the first bias voltage (Vb1) to reach the positive polarity. Pulse of voltage (Vb3).

[0020] At this time, in the first interval and the second interval, the voltage input to the X electrode is the ground voltage.

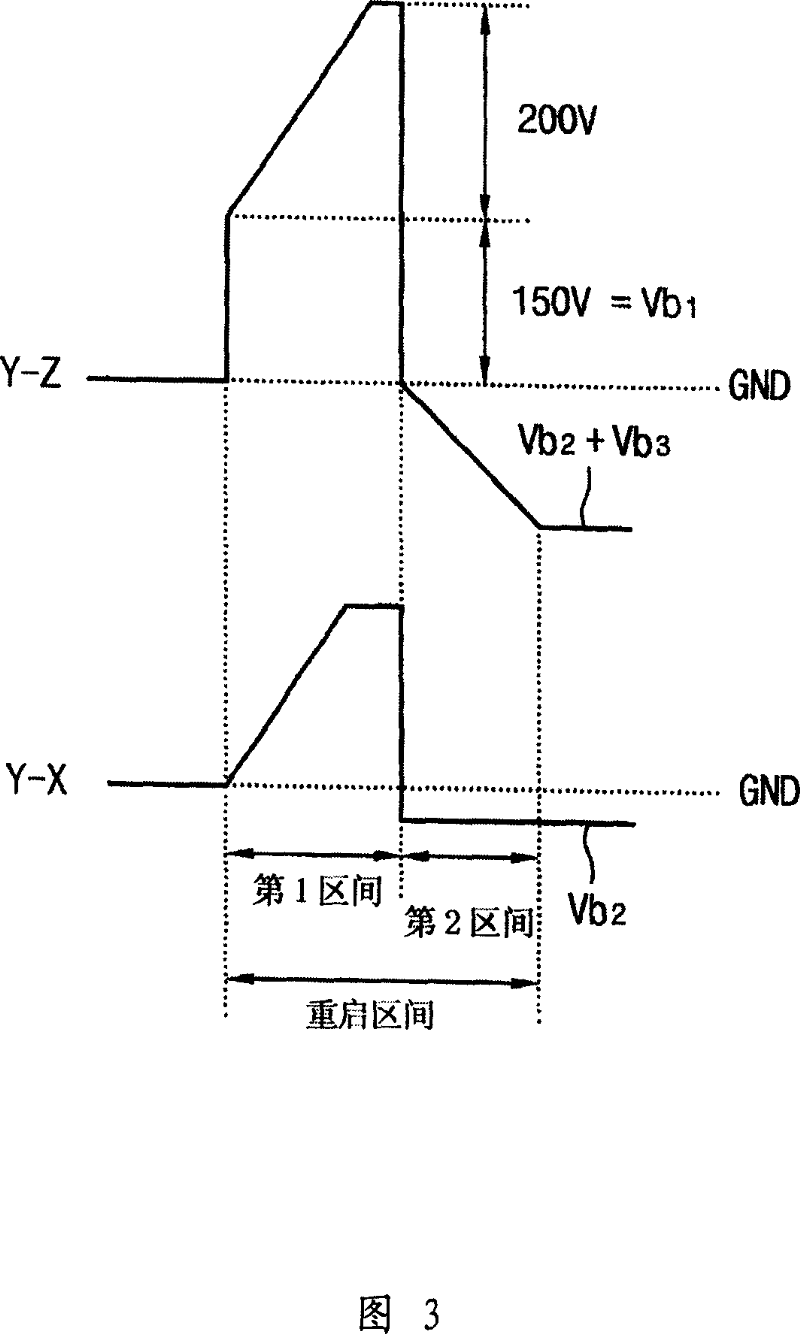

[0021] FIG. 3 shows the voltage difference formed between the Y ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com