Paper pay-out device and paper processing device

A discharge device, paper technology, applied in thin material handling, handling coins or valuable banknotes, transportation and packaging, etc., can solve problems such as jamming failure, poor discharge, etc. The effect of a large coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the present invention will be described below. The present embodiment relates to a paper discharge device that separates and discharges a plurality of paper sheets in, for example, an ATM (Automated Teller Machine: automatic teller machine) installed in a financial institution or the like. Moreover, it is related with the sheet processing apparatuses, such as an ATM.

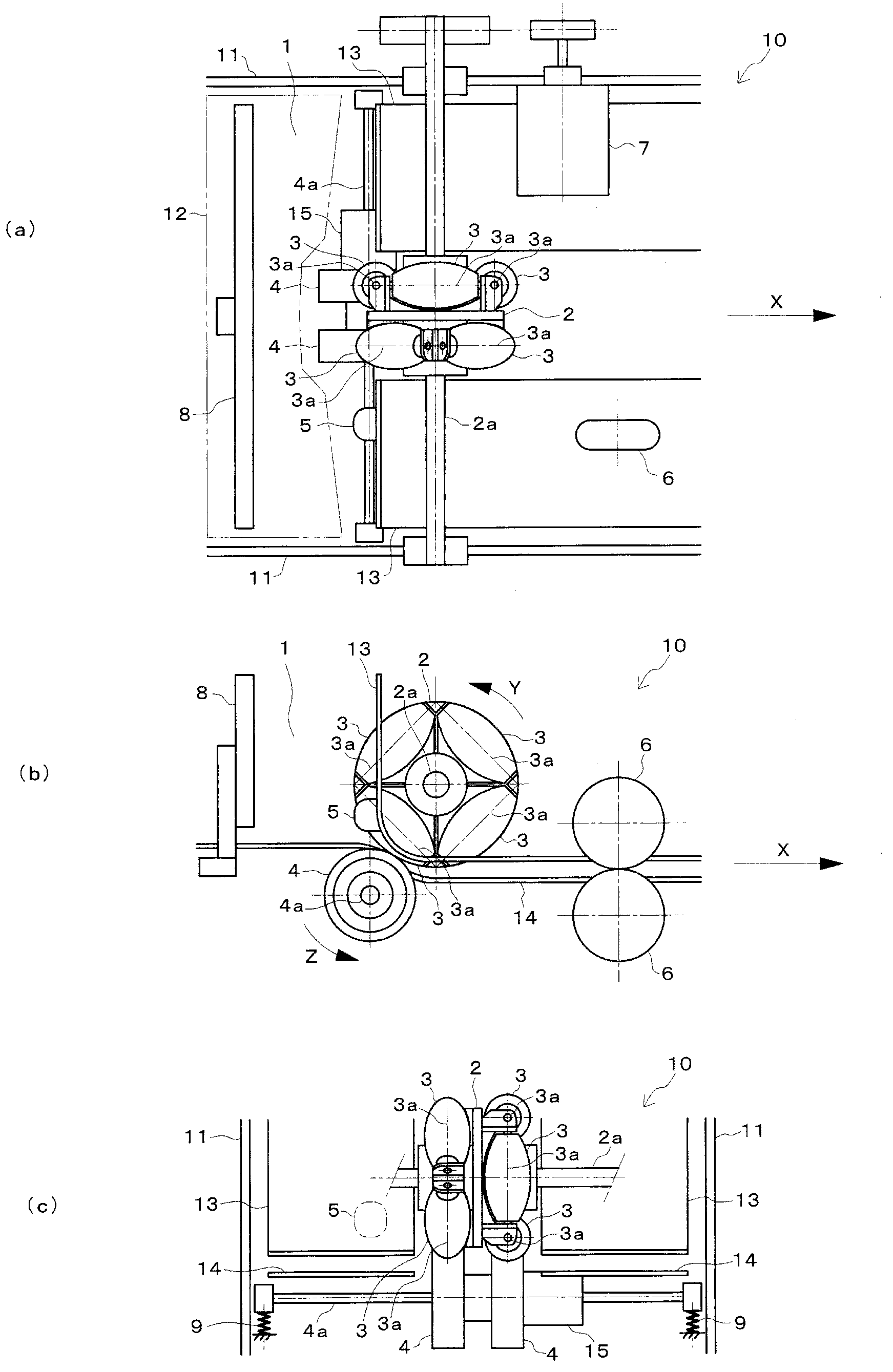

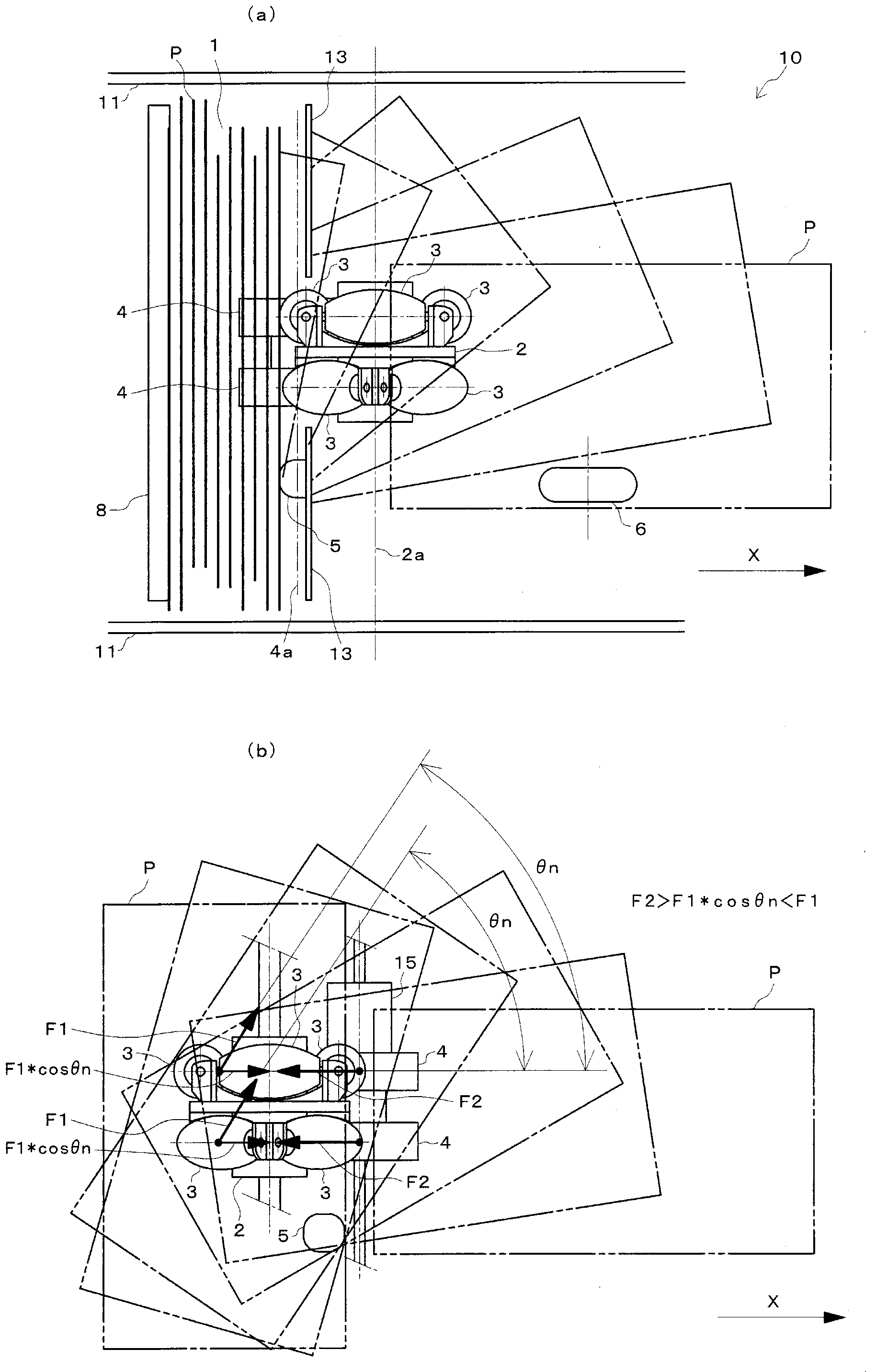

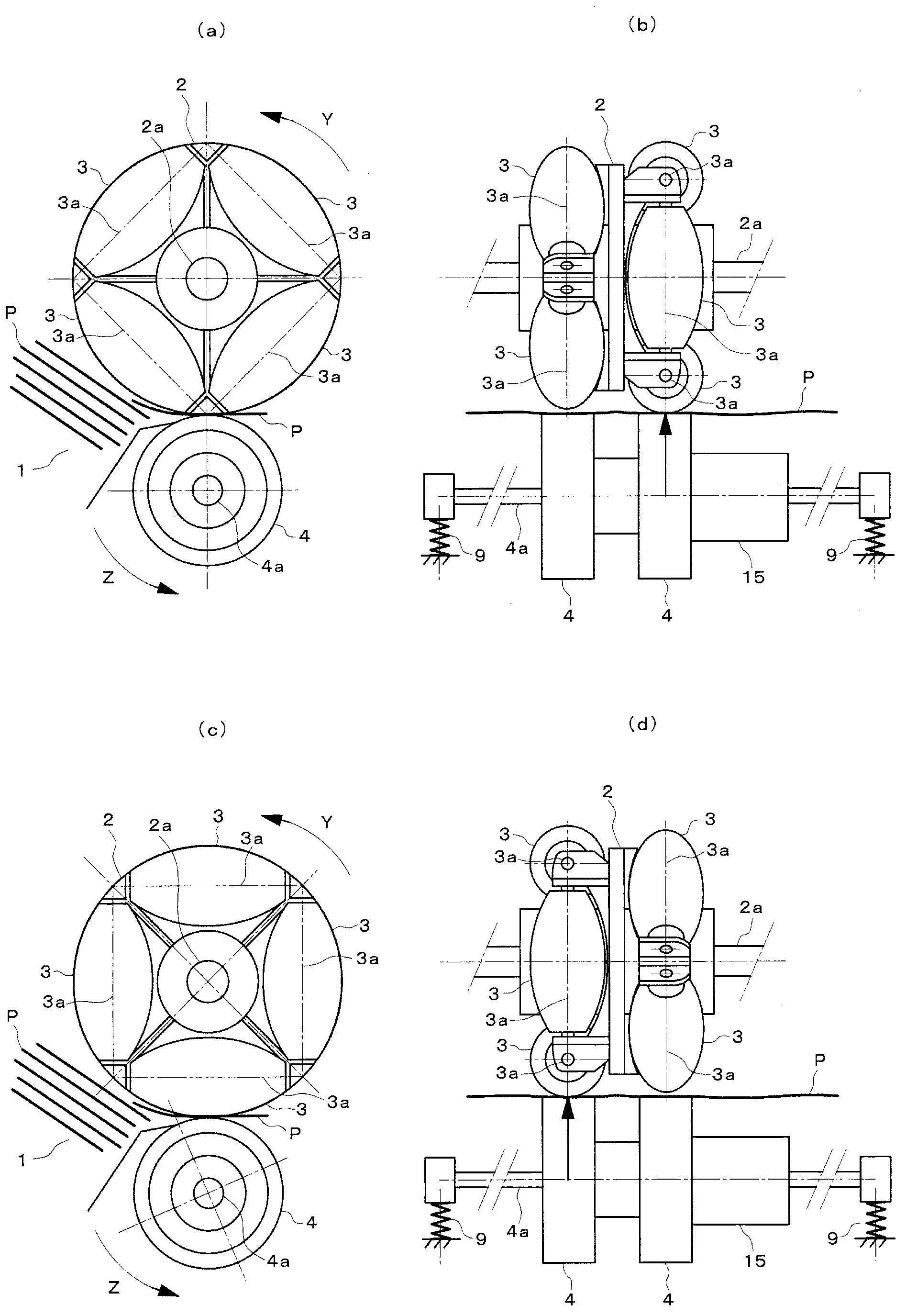

[0050] figure 1 It is a figure which shows the paper discharge apparatus 10 which concerns on one Embodiment of this invention. In detail, figure 1 (a) shows a view of the sheet discharge device 10 viewed from above, figure 1 (b) represents a view viewed from the side, figure 1 (c) expressed in figure 1 View from the right in (b). Figure 2 ~ Figure 4 It is a diagram showing the discharge state of sheets by the sheet discharge device 10 .

[0051] The loading unit 1 is constituted by a space surrounded by the side wall 11 and the guide unit 12 of the sheet discharge device 10 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com