Equipment at a lift cage for temporarily coupling a cage door leaf with a shaft door leaf and for actuation of a cage door unlocking means

一种轿厢门扇、耦合件的技术,应用在轿厢门扇与竖井门扇耦合和对轿厢门去闩锁件促动的装置领域,能够解决增大弯曲应力、增大弹簧断裂的风险等问题,达到低摩擦损耗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

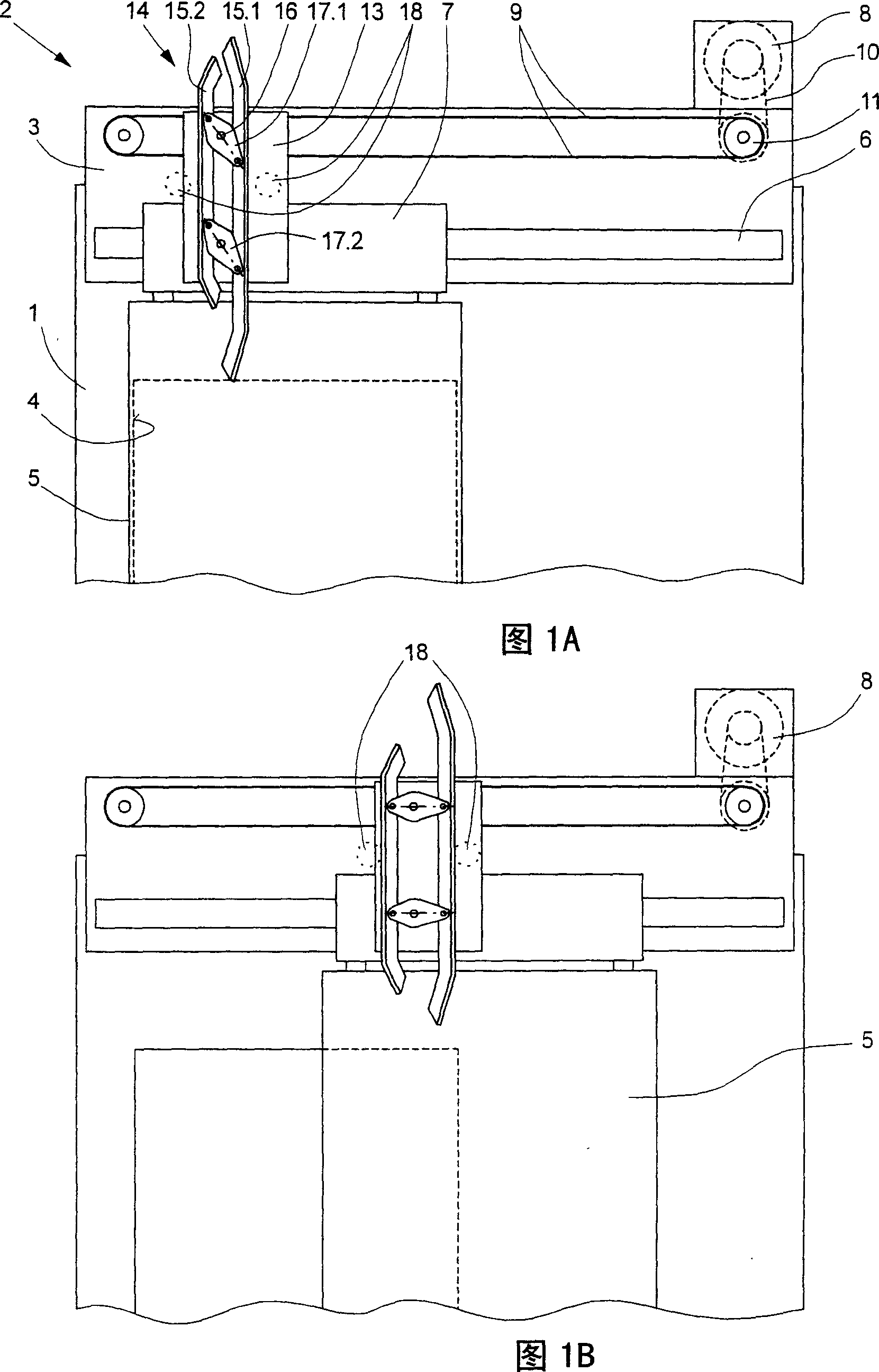

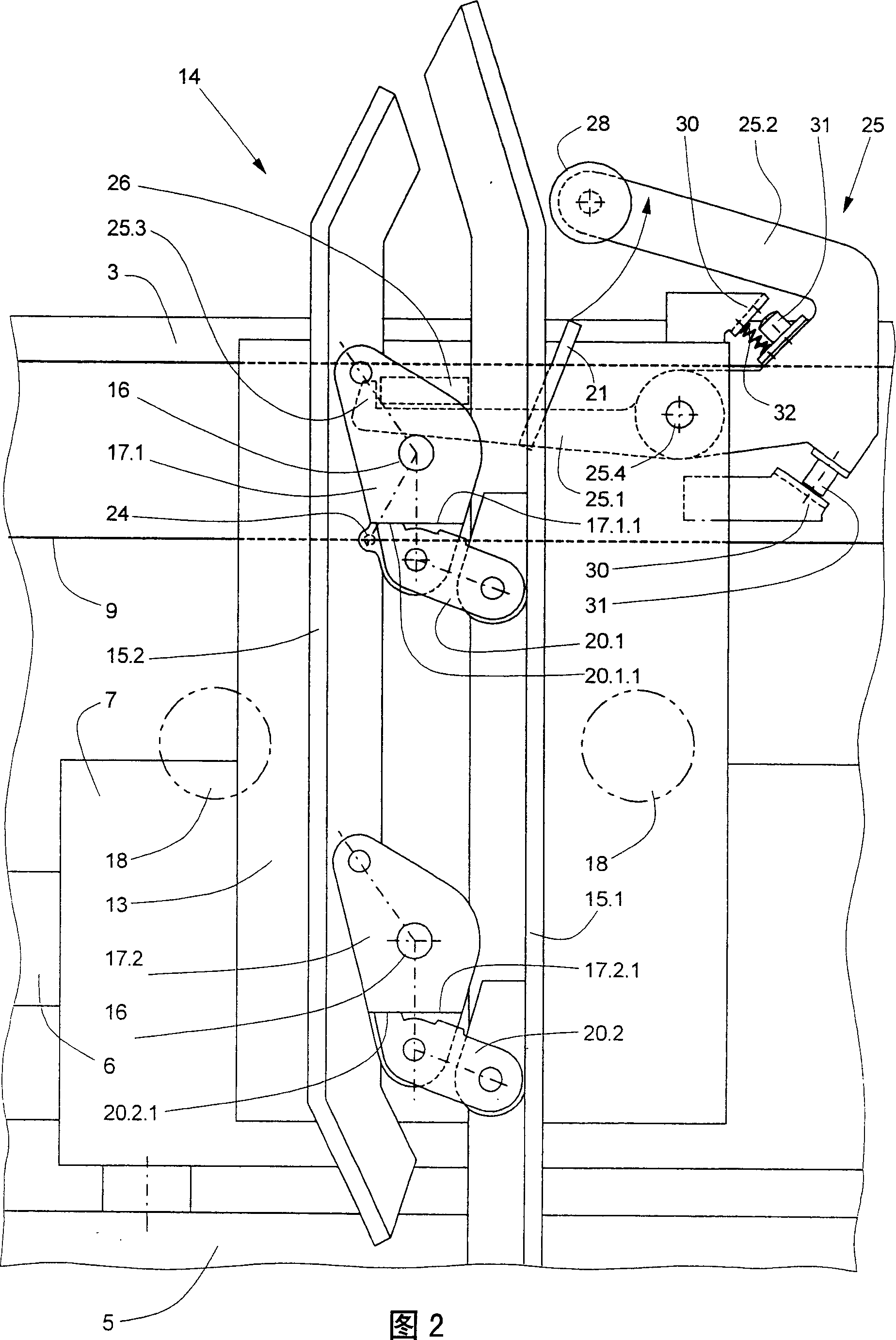

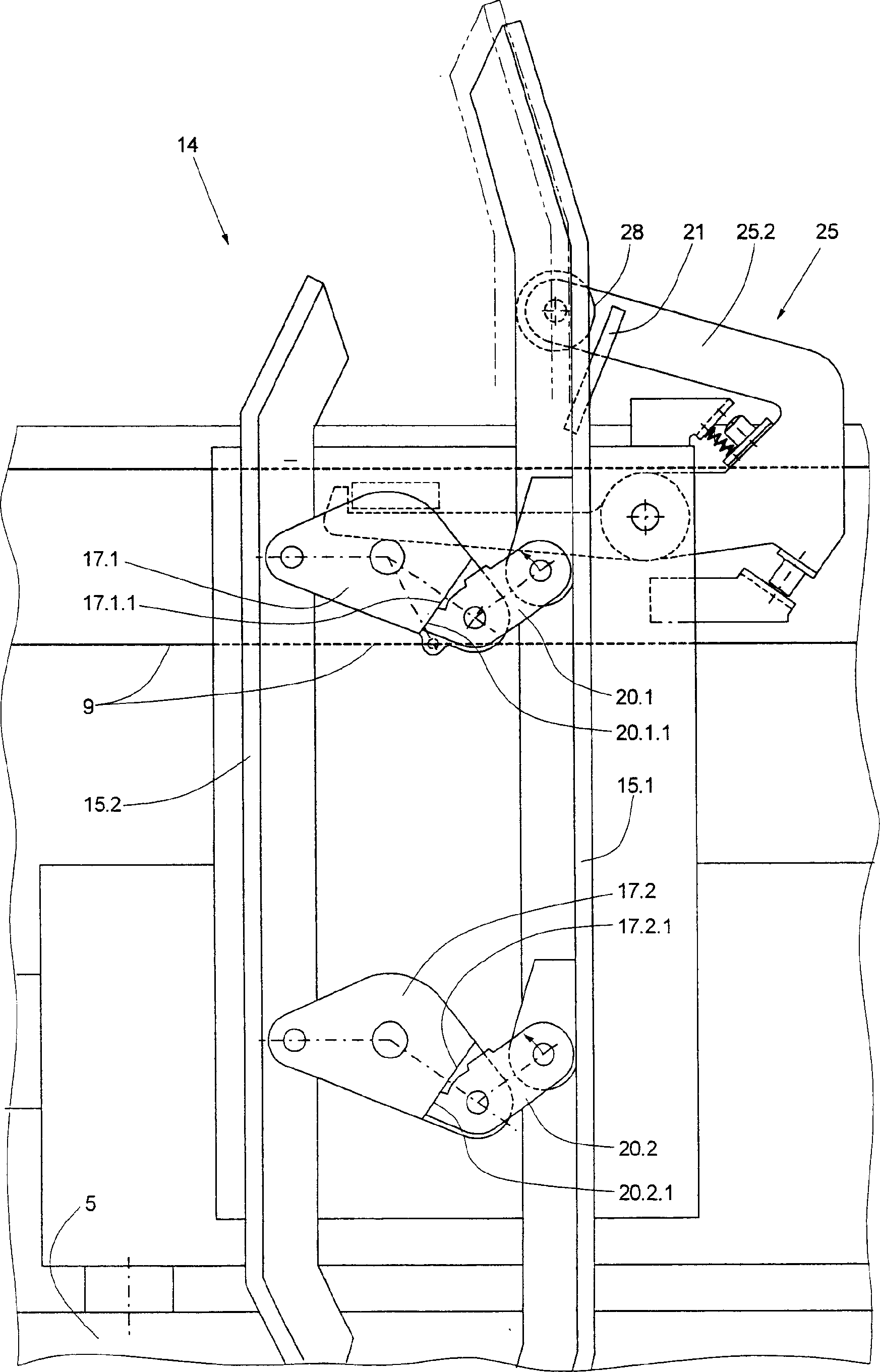

[0029]Figures 1A and 1B schematically show an electric door drive device 2, which is installed on an elevator car 1 for lateral closing of a single door. In the figure, an elevator car 1 with a door opening 4 that can be closed by a car door leaf 5 is shown. The elevator door driving device 2 is installed on a door bracket 3 which is fixed on the elevator car 1. The door leaf 5 is fixed on the hanging door sliding seat 7, and the hanging door sliding seat 7 can move laterally along a guide rail 6 fixed on the door bracket, and the hanging door sliding seat is driven by a linear action reciprocating drive through the drive unit 8. The device moves between the open position of the door leaf and the closed position of the door leaf. The motor drives the driving wheel 11 of the linearly acting driving member 9 through the transmission member 10 at an adjusted or unadjusted rotation speed, and functions as the driving unit 8. The linearly acting drive member 9 can be a toothed belt, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com