Method for producing a semiconductor component

A semiconductor and component technology, which is applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, and semiconductor/solid-state device components, etc., can solve problems such as component damage, and achieve the effect of reducing danger and avoiding the risk of damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

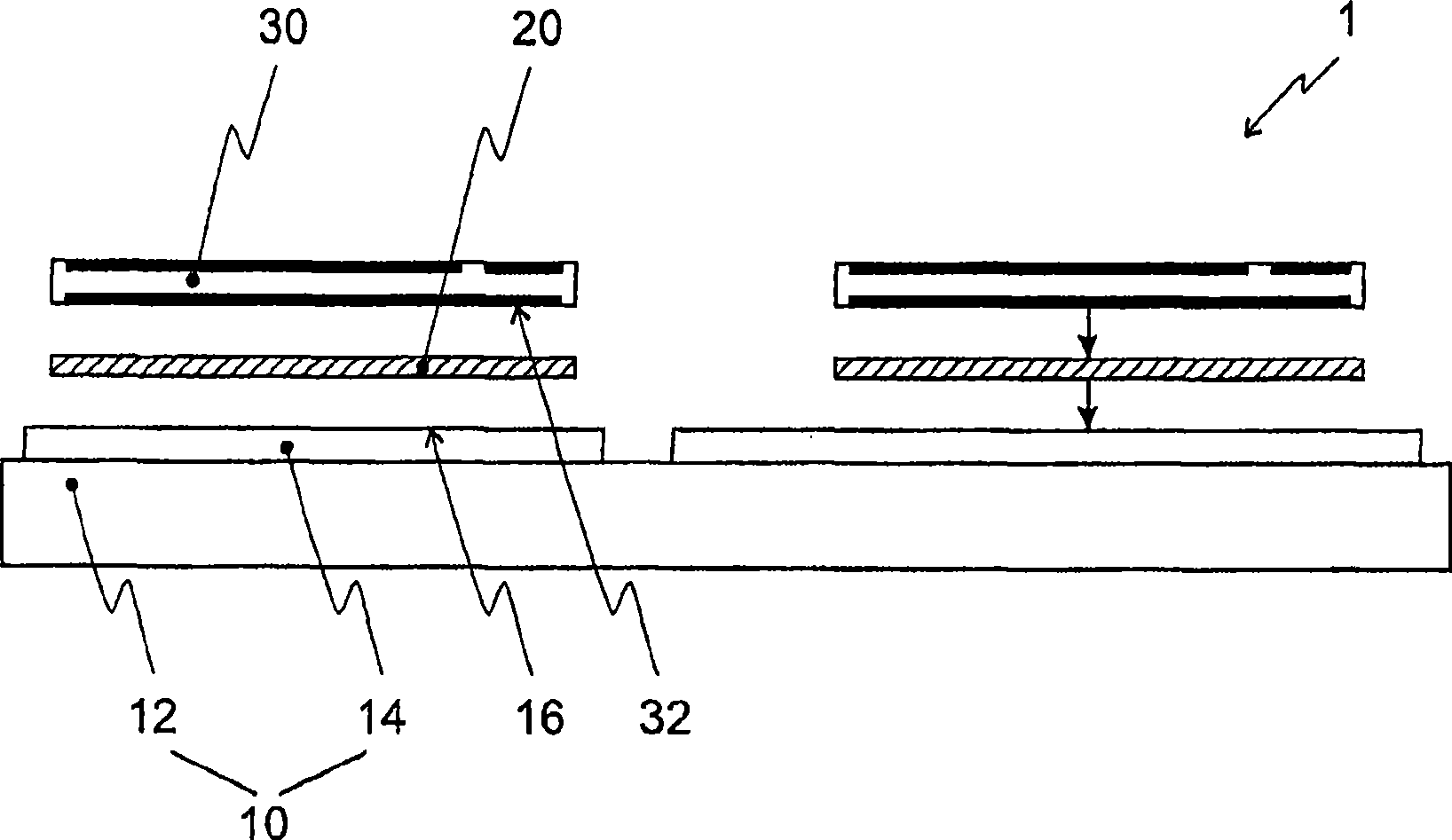

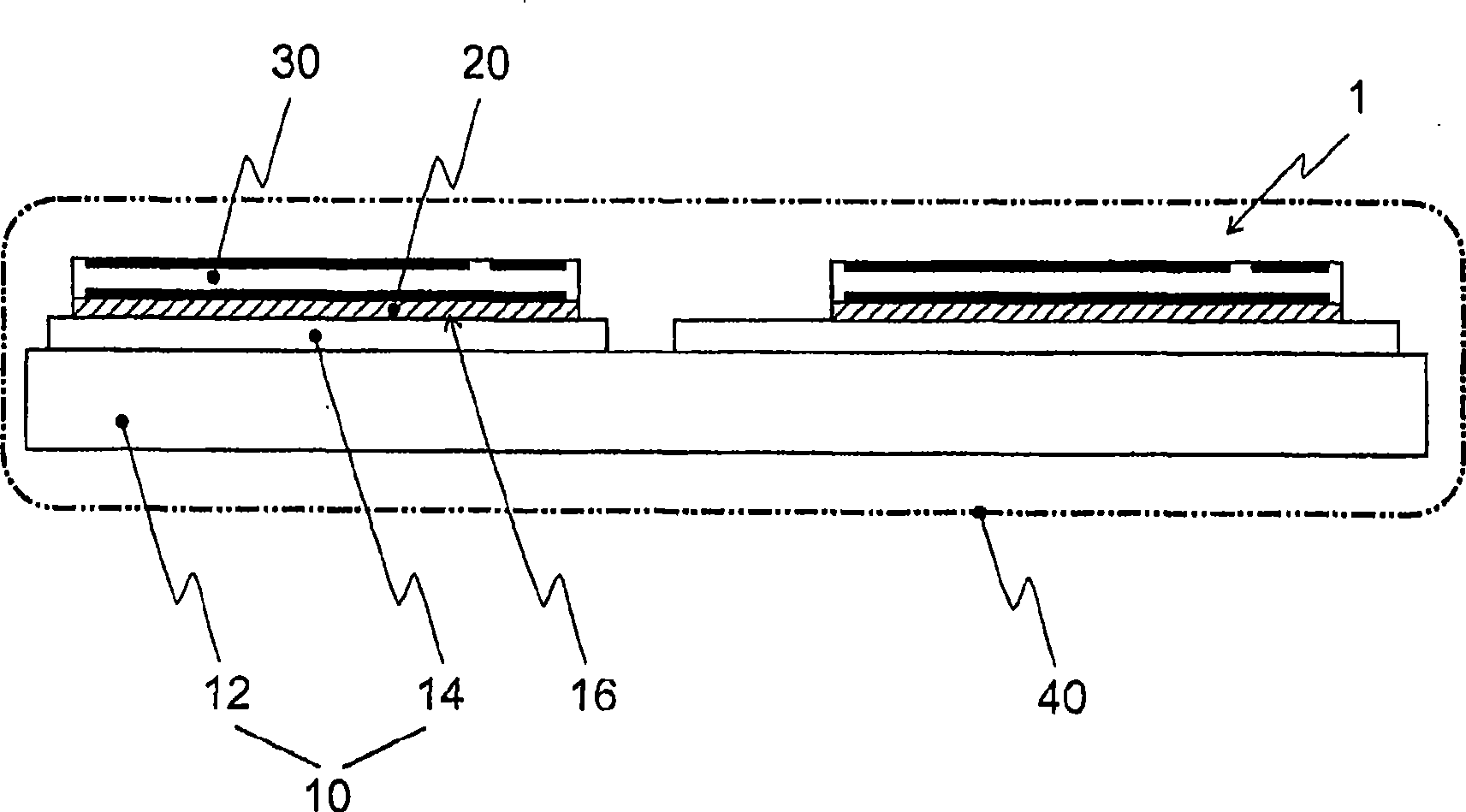

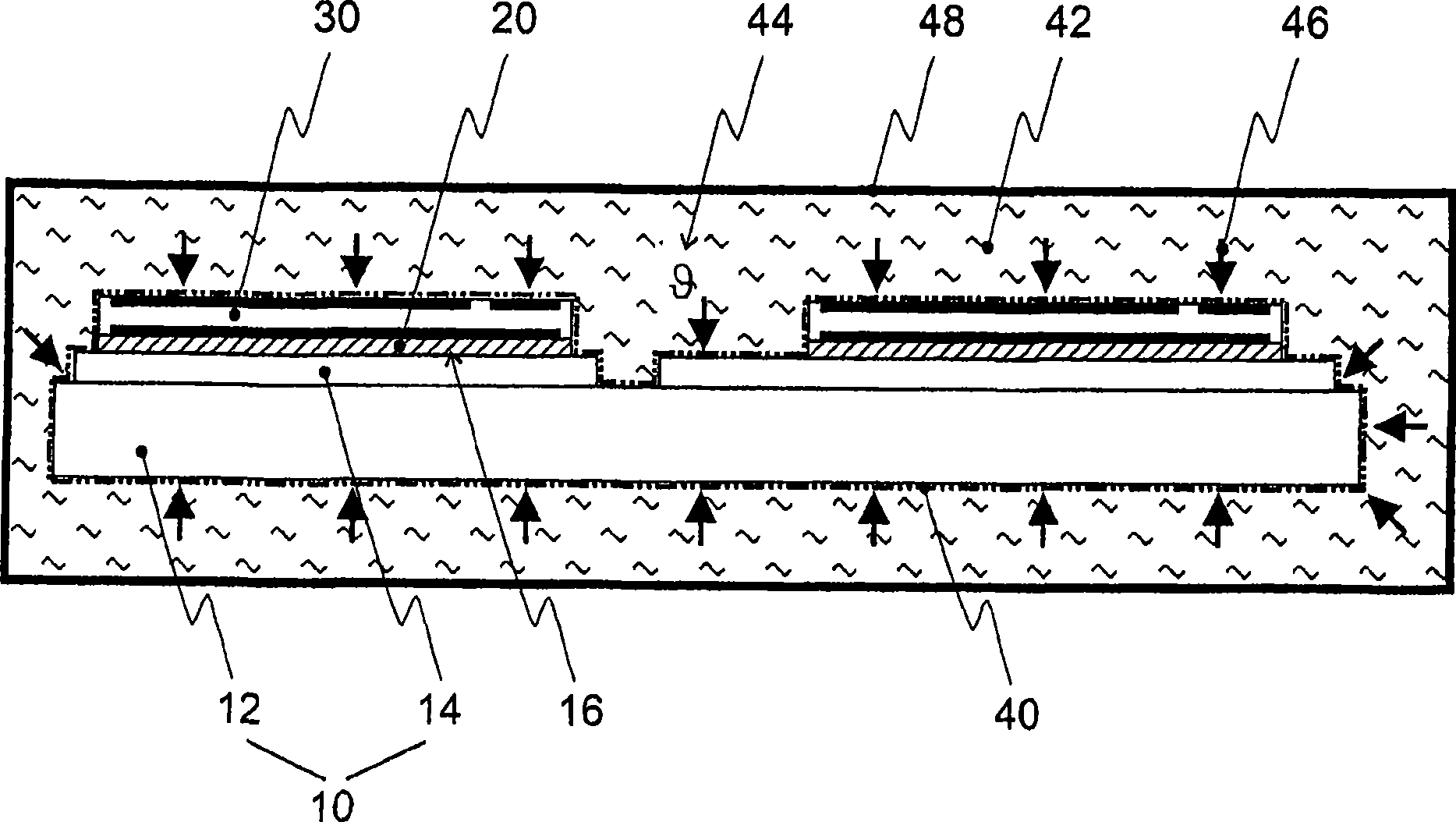

[0021] figure 1 The first step of the semiconductor component manufacturing method according to the present invention is shown. The connecting device is designed here as an electrically insulating substrate 10 which, according to the prior art, has an insulating base body 12 and a plurality of conductor tracks 14 arranged on at least one main surface and contact areas 16 formed thereon. In the case of sinter bonding, according to the prior art, it is advantageous for the contact surface 16 to have a noble metal surface. The substrate 10 is preferably designed as a conventional printed circuit board, IMS (isolated metal substrate) or DBC (direct copper connection) substrate. The exemplary embodiment of the connection means as substrate 10 does not limit the generality of the above description. It is likewise conceivable for the connection unit (see FIGS. 4 to 6 ) to be used to bond a substrate or one or more semiconductor components for internal and / or external contacting.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com