On-line type turnover mechanism for hub

A technology of overturning mechanism and overturning structure, which is applied in the direction of conveyor objects, metal processing, transportation and packaging, etc. It can solve the problems of low off-line production efficiency, damage, troublesome equipment maintenance and upgrading of production lines, etc., so as to improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

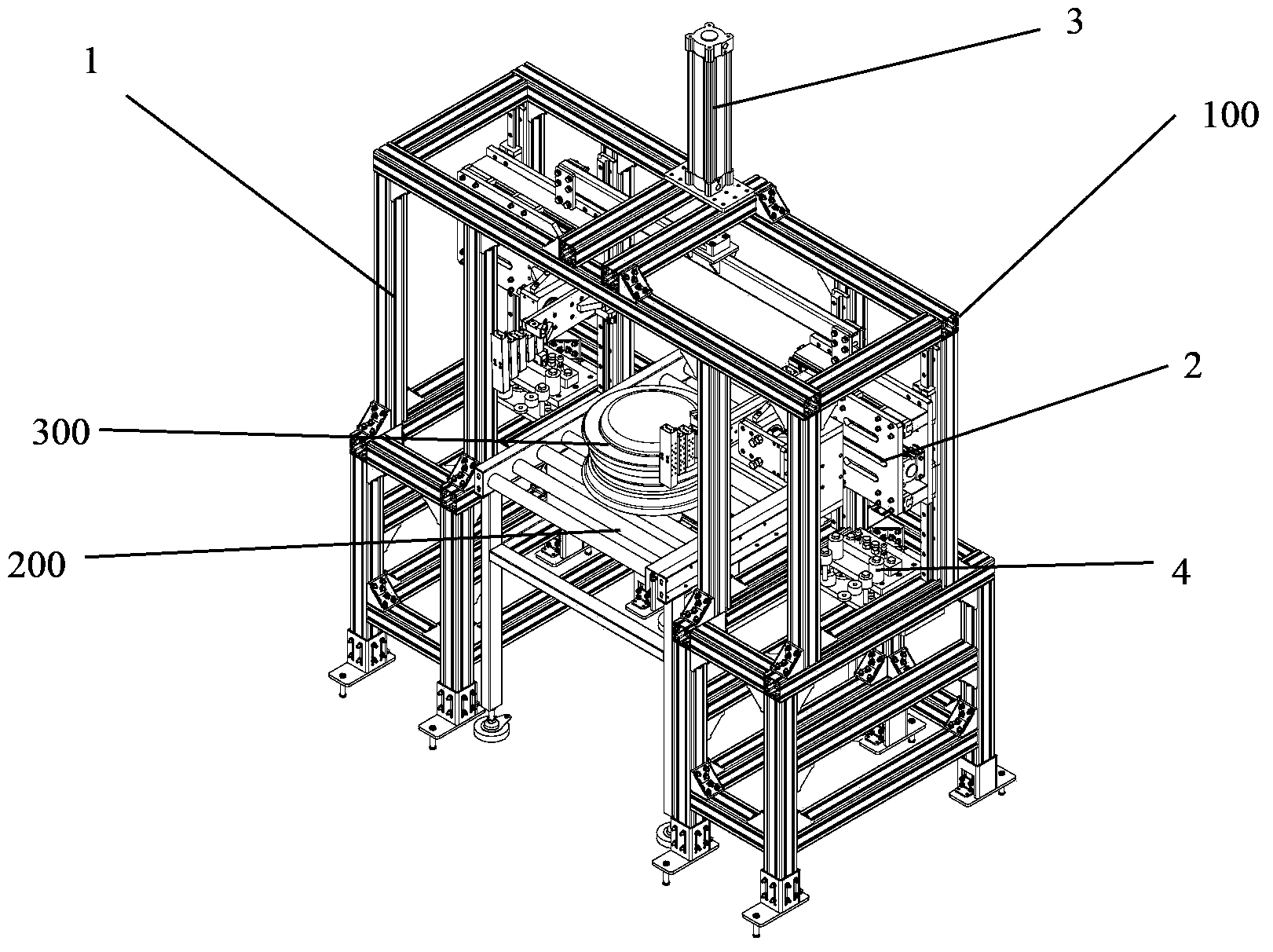

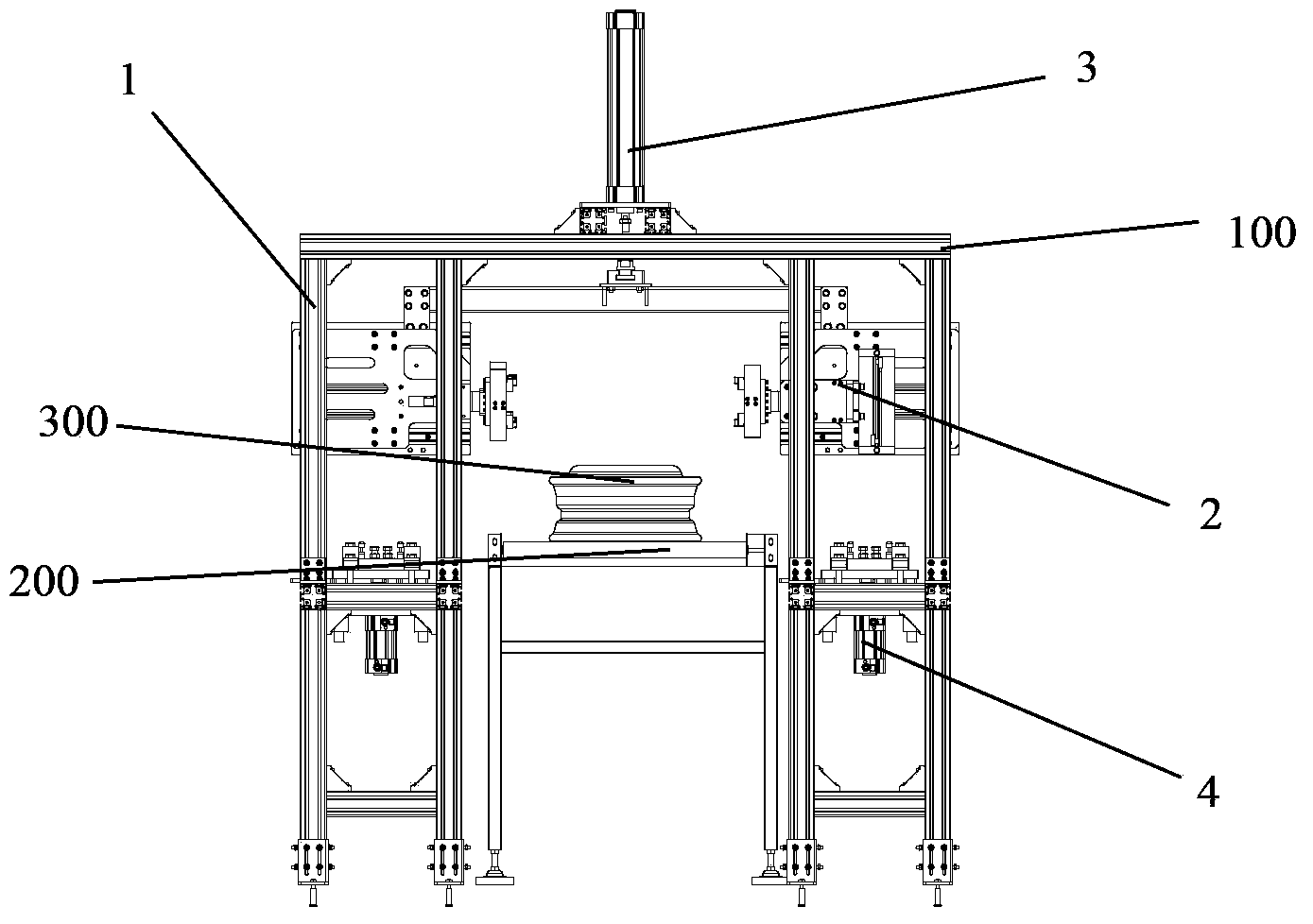

[0031] The invention discloses an independent wheel hub on-line turning mechanism. The wheel hub on-line turning mechanism is not connected to the assembly line conveyor belt and does not damage the modular design of the assembly line; its stroke can be compensated and can be adapted to different types of wheel hubs, even if the wheel hubs are asymmetrical. , and will not cause damage.

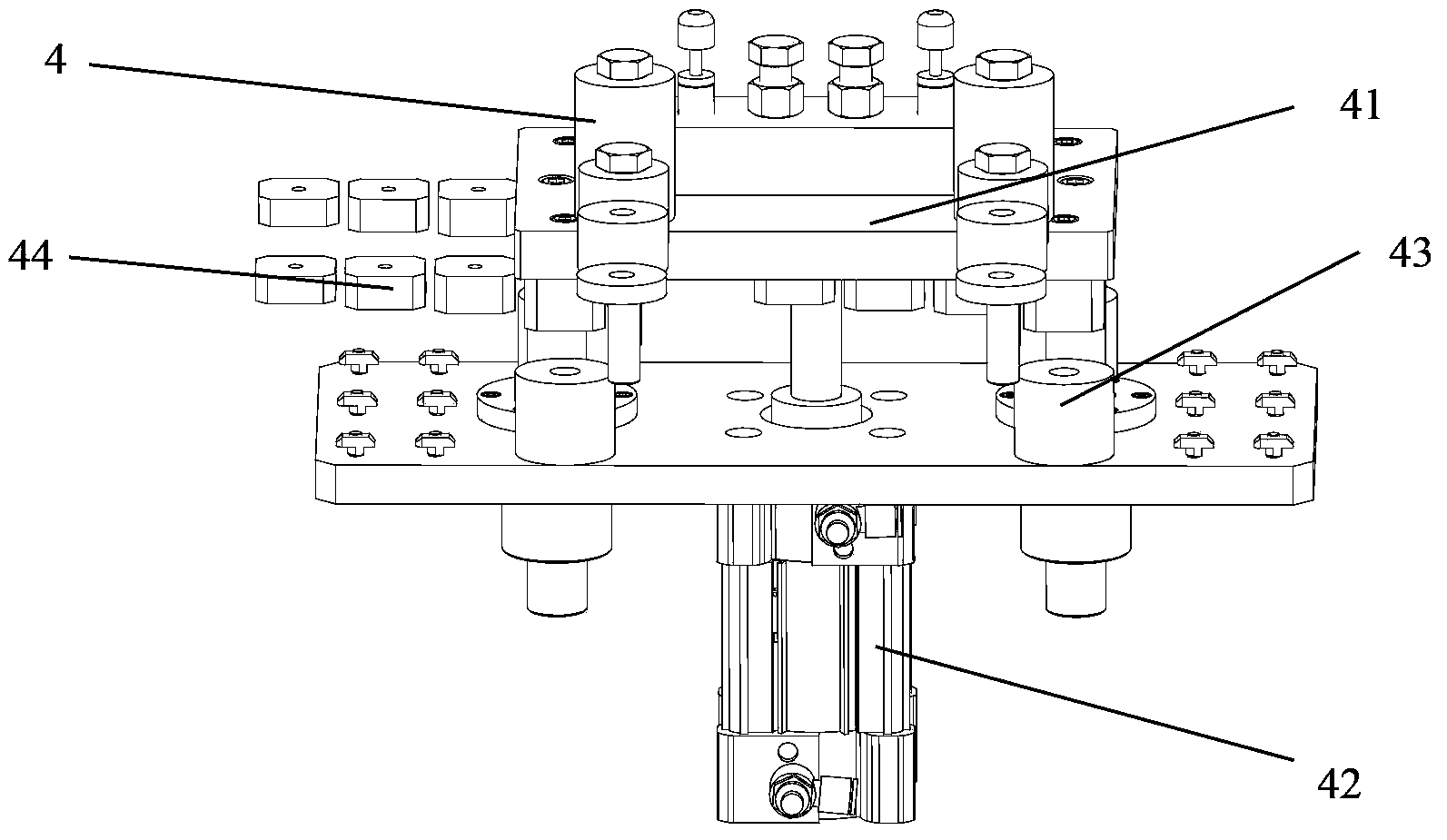

[0032] The wheel hub online turning mechanism includes a support frame, a clamping and turning structure installed on the supporting frame, and the clamping and turning structure includes a pair of manipulators arranged opposite to each other to clamp the wheel hub, and a pair of manipulators respectively controlling the two manipulators for clamping or A telescopic cylinder for loosening motion and a pair of rotating cylinders for respectively controlling two manipulators to perform flipping motions. The hub online flipping mechanism also includes a stroke compensation structure. The stroke co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com