Cylindrical coordinate robot

A technology of cylindrical coordinates and robots, which is applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as weak rigidity, large footprint, and uncompact structure, and achieve good stability and rigidity, and occupy an area Small, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

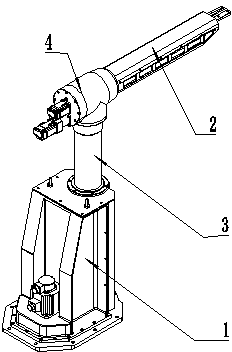

[0026] Example 1 :like Figure 1-9 As shown, a cylindrical coordinate robot includes a Z-axis 1 that can move in the Z-direction, an X-axis 2 that can move in the X-direction, a rotation axis 3 that can rotate in the Z-direction, and a flip axis that can rotate in the X-direction 4; wherein, the rotation axis 3 is arranged on the Z axis 1 , the inversion axis 4 is arranged on the rotation axis 3 , and the X axis 2 is arranged on the inversion axis 4 .

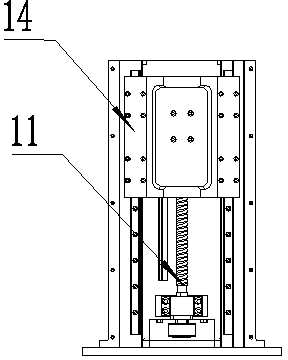

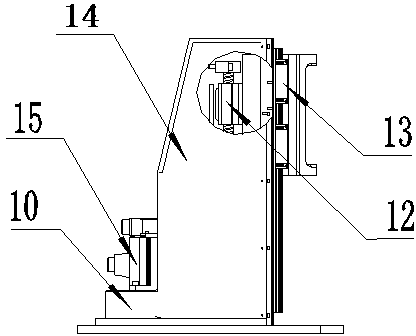

[0027] The Z-axis 1 includes a base 10 on which a lead screw transmission device 11 is arranged along the Z direction, and the lead screw transmission device 11 includes a nut seat 12 on which Z is arranged. The shaft lifting seat 13 is provided with a casing 14 fixed on the base 10 outside the screw drive 11 , and an AC for driving the screw drive 11 is also provided on the base 10 Servo motor 15.

[0028] The rotating shaft 3 includes an AC servo motor 30, a planetary reducer 31 and a transmission shaft 32 arranged along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com