Double connecting rods type reversible table

A technology of flipping table and double connecting rod, which is applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of low tonnage of operable workpieces, high energy consumption and low safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

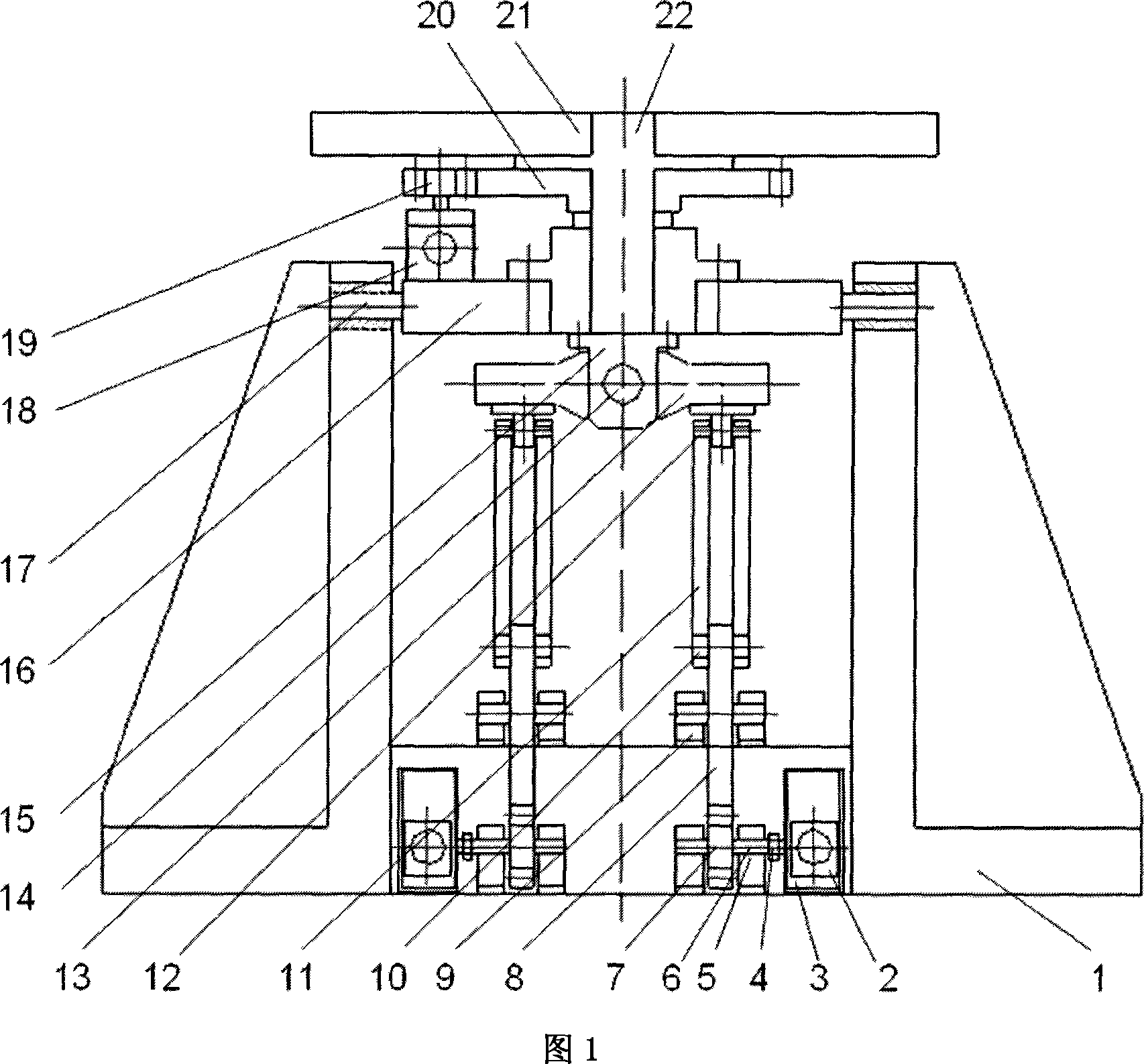

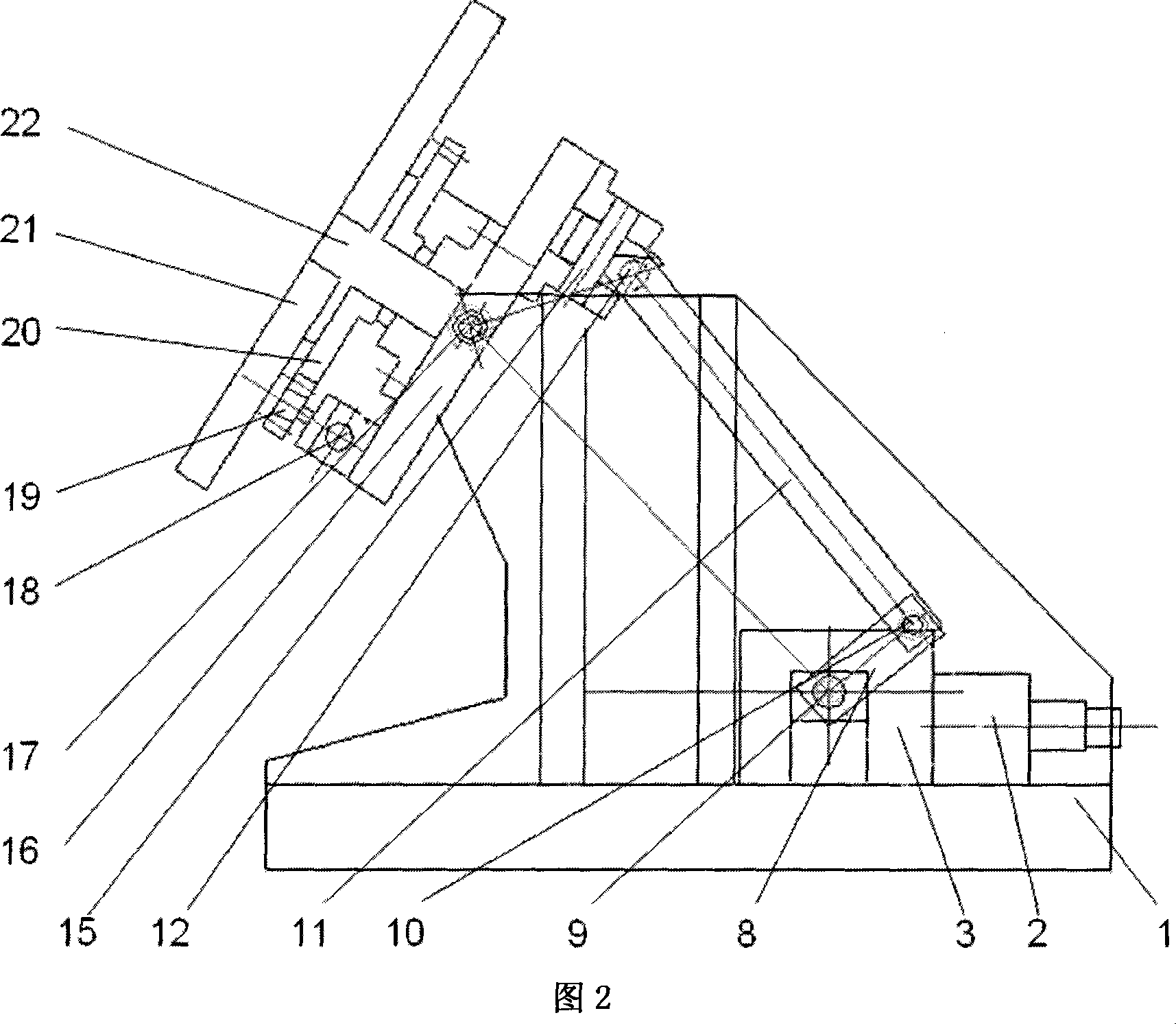

[0016] Shown in Fig. 1 is the front view of the overall structure of the present invention. The present invention mainly includes: a rotating table 21 and an overturning system for driving the rotating table 21, characterized in that the overturning system is composed of a table pitching mechanism for realizing the pitching of the rotating table 21 and a table turning mechanism for realizing the rotation of the rotating table 21.

[0017] The table pitching mechanism includes a platform 1, two main motors 2, two reducers 3, two couplings 4, two fixed seats 5, four fixed hinges 6, two pinions 7, two Only large gear 8, two large gear support bearings 9, two connecting rod lower hinges 10, two connecting rods 11, two connecting rod upper hinges 12, one coordinating rod 13, one coordinating rod hinge 14, one Turn over stand connecting seat 15, tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com