Automatic feeder for bamboo strips

A technology of feeding device and bamboo strips, which is applied to conveyor objects, transportation and packaging, grinding and feeding motion, etc., can solve the problems of large volume, large liquid surface area and high cost of the turning device, and achieve the effect of solving high labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The realization, functional characteristics and implementation effects of the present invention will be further described below in conjunction with specific embodiments and accompanying drawings. The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it.

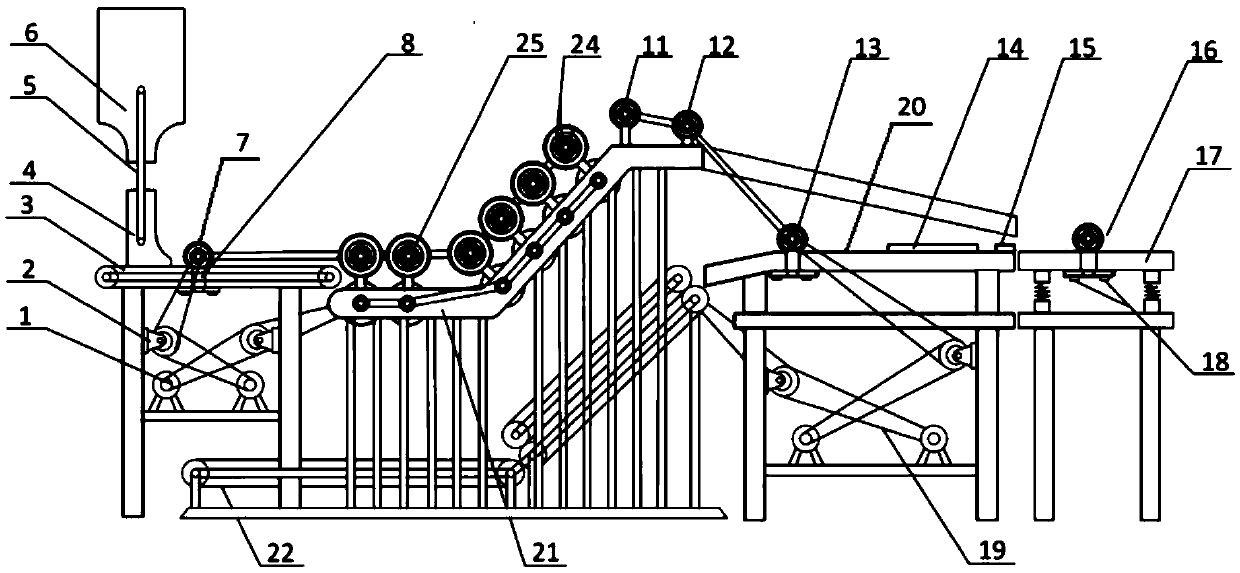

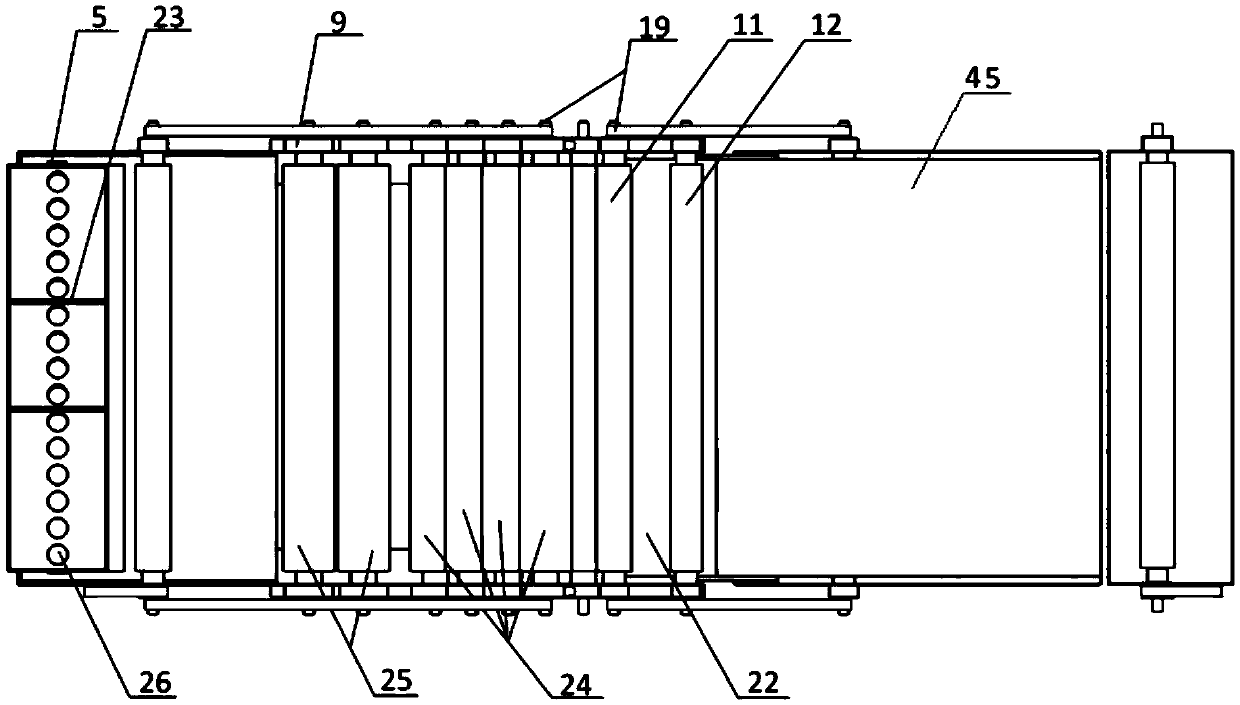

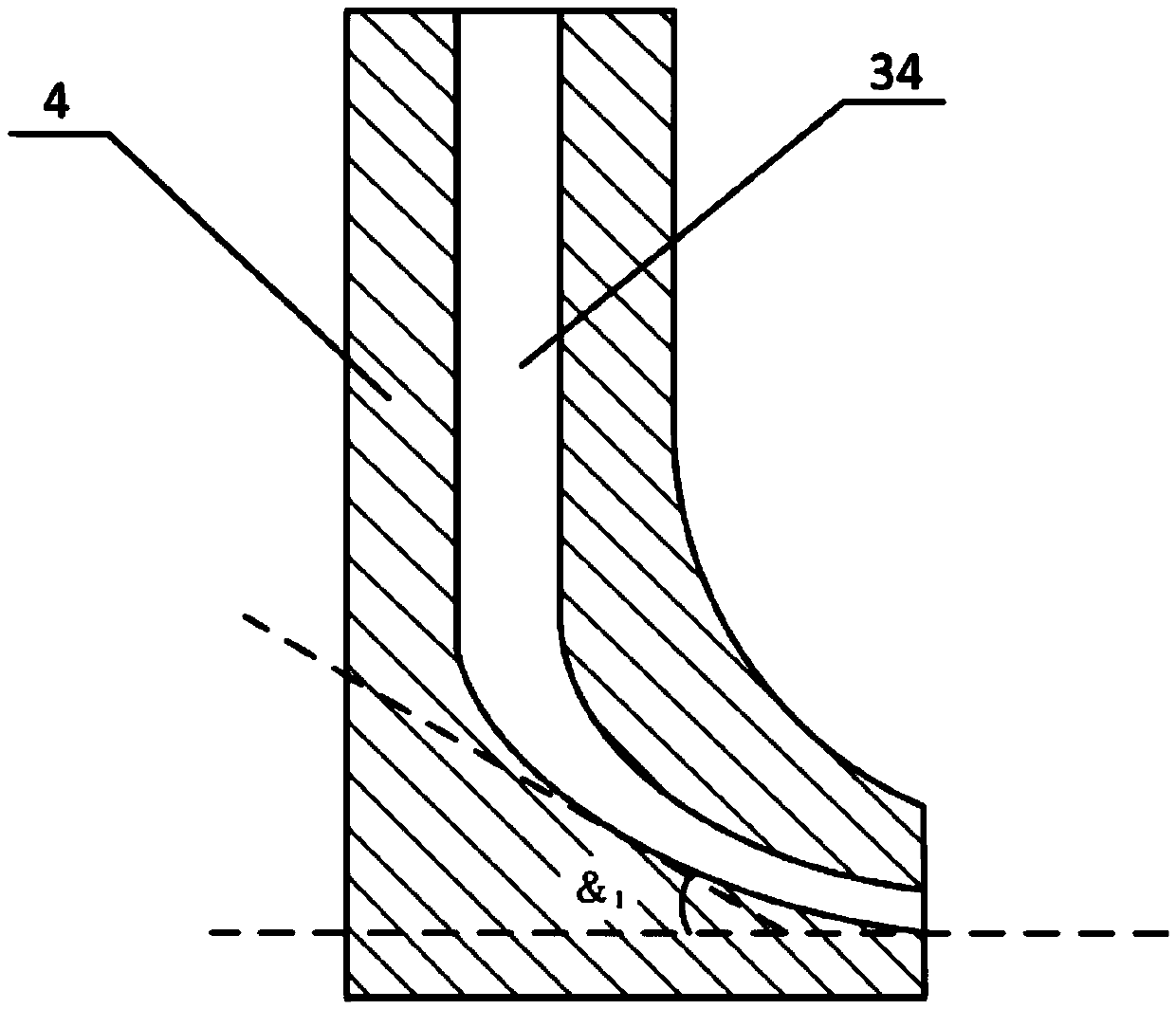

[0062] Such as figure 1 As shown, an automatic feeding device for bamboo strips, including a feeding mechanism, an identification and sorting mechanism for identifying bamboo strips in different orientations, a material receiving mechanism for accepting bamboo strips with the green side up, and a turning mechanism for turning over the bamboo strips with the green side up , a conveying mechanism for guiding the bamboo strips with the yellow side up, and an output mechanism for outputting the bamboo strips with the yellow sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com