Turning device for assembling tires of heavy duty cars

A tire assembly and heavy-duty vehicle technology, which is applied in the field of automobile manufacturing, can solve the problems of low production efficiency, manipulators cannot directly grab horizontal tires, and high labor intensity, so as to improve labor efficiency, compact structure, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

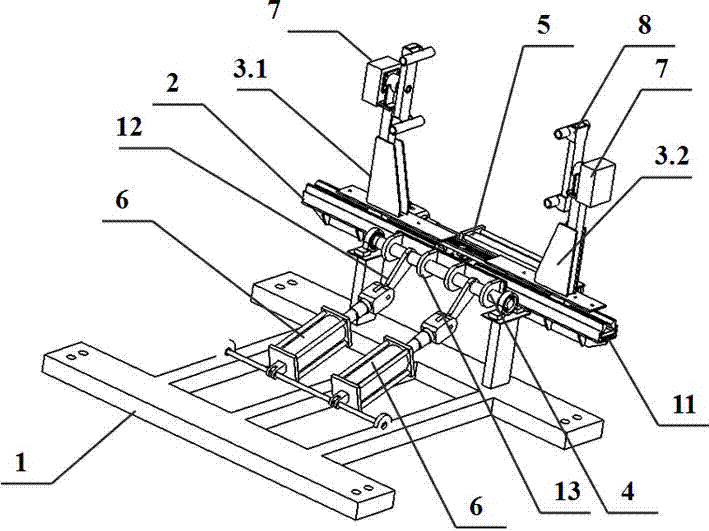

[0027] see figure 1 , The overturning device for heavy-duty vehicle tire assembly includes an overturning frame 1 and an overturning clamp arm mechanism 2 .

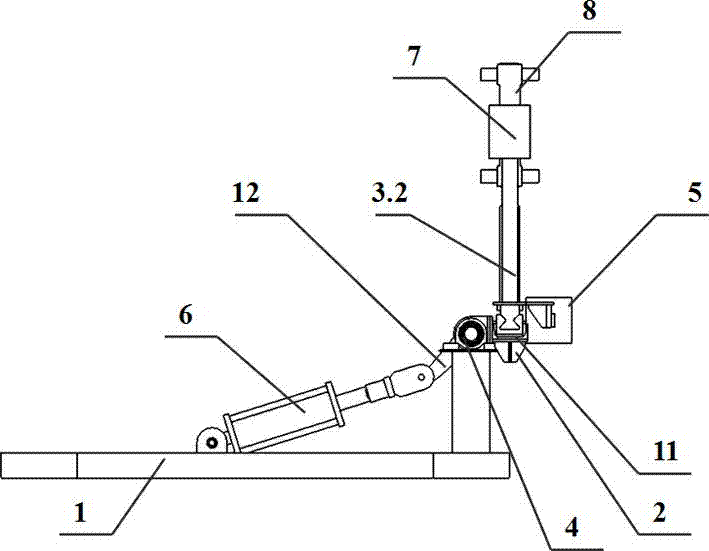

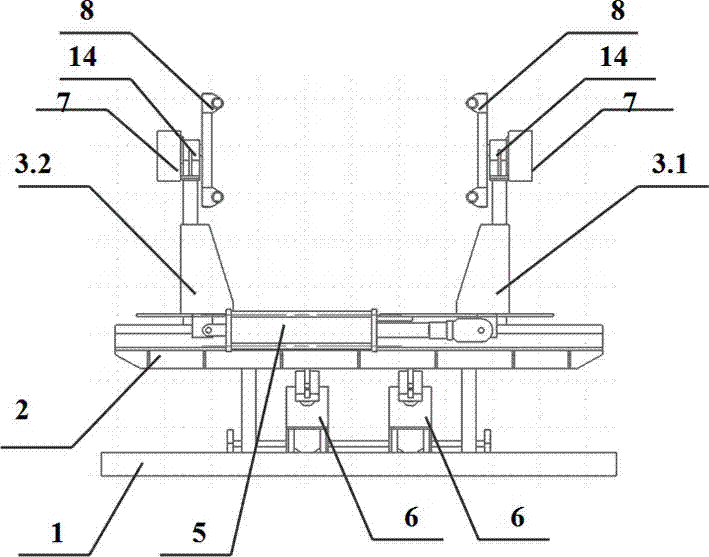

[0028] The overturning frame 1 is a welded piece of steel structure in the shape of a plane frame, and two uprights are evenly distributed on one side of it. The tops of the two uprights are installed with the rotating shaft 4 through the bearing of the bearing seat, and the middle part of the rotating shaft 4 is evenly arranged. Two connecting rods 12, the other ends of the two connecting rods 12 are respectively movably connected to the piston rods of two overturning cylinders 6, and the cylinder bodies of the two overturning cylinders 6 are respectively fixed on the middle part of the overturning frame 1, see figure 2 , Figure 4 and Figure 5 .

[0029] The overturning clamp arm mechanism 2 comprises a channel-shaped overturning guide rail 11, and four connecting plates 13 are uniformly and fixedly installed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com