Pattern correction method of investment casting engine blade and pattern correction mould of method

A technology of engine blades and investment casting, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems that the casting deformation cannot be predicted, the casting size cannot meet the requirements, etc., and achieve the effect of improving the production pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: For a titanium alloy engine blade used on an aero-engine, the investment casting method is used to obtain a casting with almost no margin. The precision casting is 310 mm long and 50 mm wide. 7mm, the blade body of this blade is relatively thin, and it is easy to deform during the casting process. It is still difficult to make the final size of the engine blade casting meet the requirements of the design drawings through wax model calibration; the calibration method of the present invention is used to correct the engine blade The casting is corrected, the specific calibration steps are as follows:

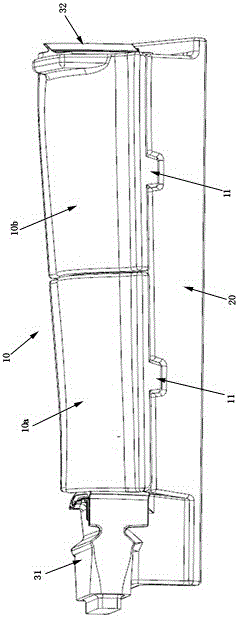

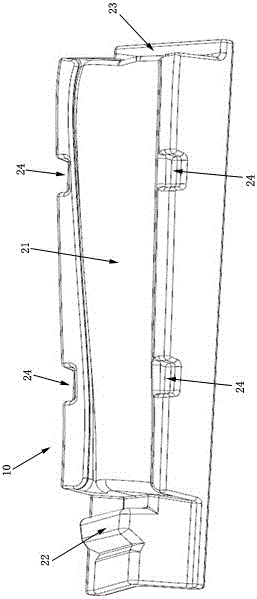

[0022] According to the size and structure of the titanium alloy blade casting, the same titanium alloy material as the casting material is used to process the special calibration mold, see figure 1 with figure 2 , the special calibration mold includes an upper mold 10 and a lower mold 20, and the upper mold 10 and the lower mold 20 are respectively processed...

Embodiment 2

[0028] The difference between this embodiment and Embodiment 1 is that the material of the mold used for calibration in Embodiment 1 is the same as that of the casting, which is a titanium alloy material. The size, weight and placement position of the molded parts have been modified. The size of the upper mold for the school mold in this embodiment is selected as 60mm wide and 220g in weight. The placement positions are respectively close to the bottom and upper part of the blade body. Other settings Same as Embodiment 1.

[0029] After the hot isostatic pressing treatment, the castings were taken out, and the size of the parts was detected by a three-coordinate instrument, and the pass rate of precision castings that met the design requirements of the drawings reached 83%.

[0030] The casting mold is used to calibrate the casting, which solves the deformation problem of the casting and achieves the purpose of precise control of the casting size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com