Size correcting method for aeroengine high-temperature alloy disc shaft abrasion

A technology for aero-engines and high-temperature alloys, applied in metal material coating technology, fusion spraying, coatings, etc., can solve problems affecting the performance of coatings and parts, poor service performance of coatings, and easy peeling of coatings, etc. Achieve the effects of improving oxidation resistance and wear resistance, improving surface integrity and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

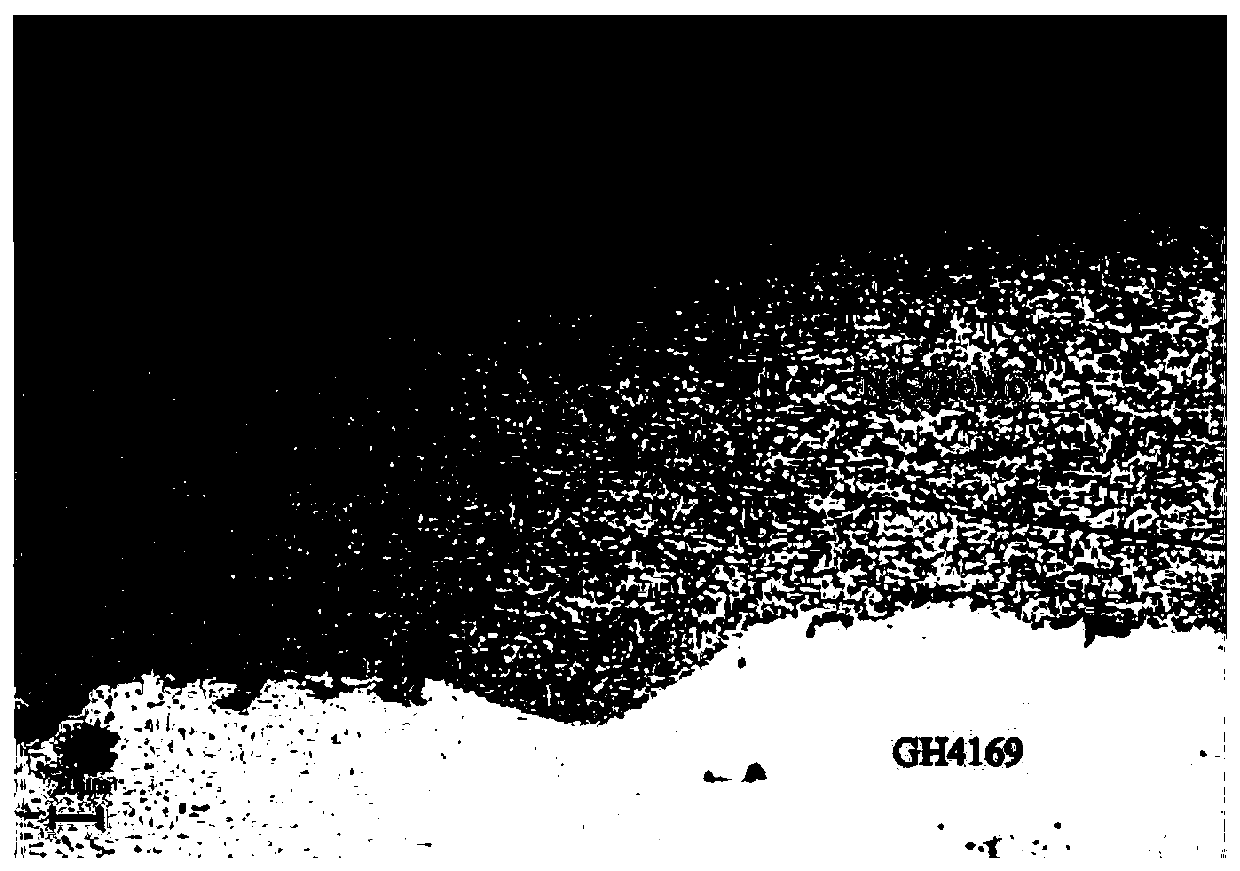

Image

Examples

Embodiment 1

[0026] A method for repairing the size of aero-engine superalloy disc shaft wear, the specific implementation steps are as follows:

[0027] (1) Parts degreasing: Before spraying the coating, use acetone to wipe the area of the parts that needs to be repaired to remove oil and debris;

[0028] (2) Protection before sand blowing: Use protective tape to protect the parts that do not need to be sprayed and repaired before sand blowing;

[0029] (3) Parts sand blowing: Sand blowing treatment is performed on the area of the parts that needs to be repaired, and the surface of the parts is activated and roughened. Among them, the sand blowing medium is 80-mesh alumina sand, the sand blowing pressure is 0.2MPa, and the roughness is 2.0 μm;

[0030] (4) Supersonic spraying: supersonic spraying NiCrFeMo coating on the area after sand blowing, wherein the kerosene flow rate is 3.5 gallons / h, the oxygen flow rate is 1600L / min, the argon gas flow rate is 10L / min, and the powder feedin...

Embodiment 2

[0034] A method for repairing the size of aero-engine superalloy disc shaft wear, the specific implementation steps are as follows:

[0035] (1) Parts degreasing: Before spraying the coating, use acetone to wipe the area of the parts that needs to be repaired to remove oil and debris;

[0036] (2) Protection before sand blowing: use glass fiber cloth to protect the parts that do not need spraying and repairing before sand blowing;

[0037] (3) Parts sand blowing: Sand blowing treatment is performed on the area where the parts need to be repaired, and the surface of the parts is activated and roughened. Among them, the sand blowing medium is 60-mesh alumina sand, the sand blowing pressure is 0.3MPa, and the roughness is 2.5 μm;

[0038] (4) Supersonic spraying: supersonic spraying NiCrFeMo coating on the area after sand blowing, wherein the kerosene flow rate is 7 gallons / h, the oxygen flow rate is 600L / min, the argon gas flow rate is 10L / min, and the powder feeding rate is ...

Embodiment 3

[0041] A method for repairing the size of aero-engine superalloy disc shaft wear, the specific implementation steps are as follows:

[0042] (1) Parts degreasing: Before spraying the coating, use gasoline to wipe the area of the parts that needs to be repaired to remove oil and debris;

[0043] (2) Protection before sand blowing: Use tooling to protect the parts of the parts that do not need to be sprayed and repaired before sand blowing;

[0044] (3) Parts sand blowing: Sand blowing treatment is performed on the area of the parts that needs to be repaired to activate and roughen the surface of the parts. Among them, the sand blowing medium is 70 mesh alumina sand, the sand blowing pressure is 0.2MPa, and the roughness is 2.3 μm;

[0045] (4) Supersonic spraying: supersonic spraying NiCrFeMo coating on the area after sand blowing, wherein the kerosene flow rate is 5 gallons / h, the oxygen flow rate is 1000L / min, the argon gas flow rate is 10L / min, and the powder feeding ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com