Suction crane

A hoist and boom technology, applied in the field of hoisting devices, can solve the problems of increased weight of the suction hoist, increased failure rate, and the inability of the suction hoist to meet the movement and placement of irregular-shaped glass or plates, and achieves processing and Easy installation, reduced weight, and enhanced work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

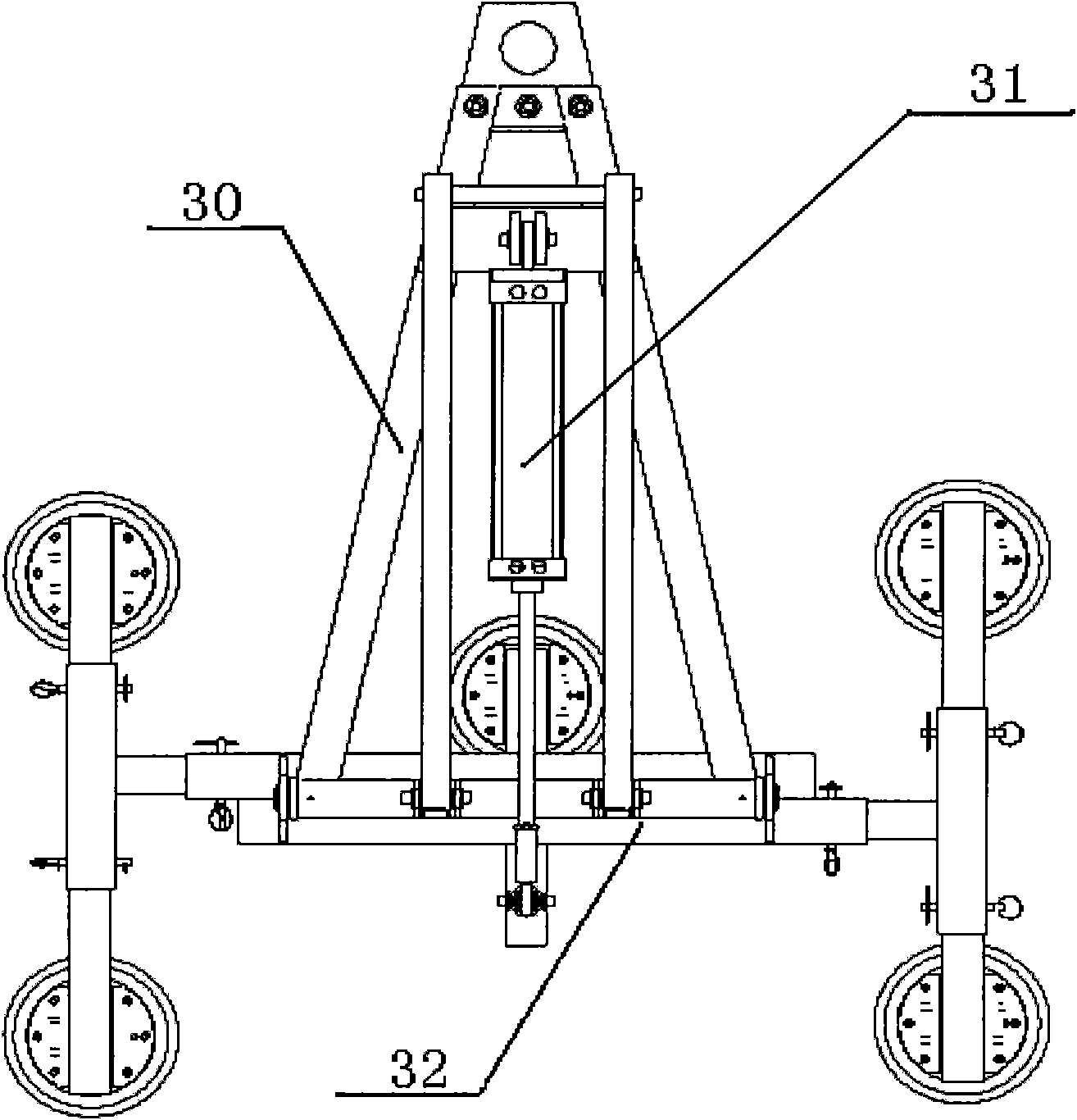

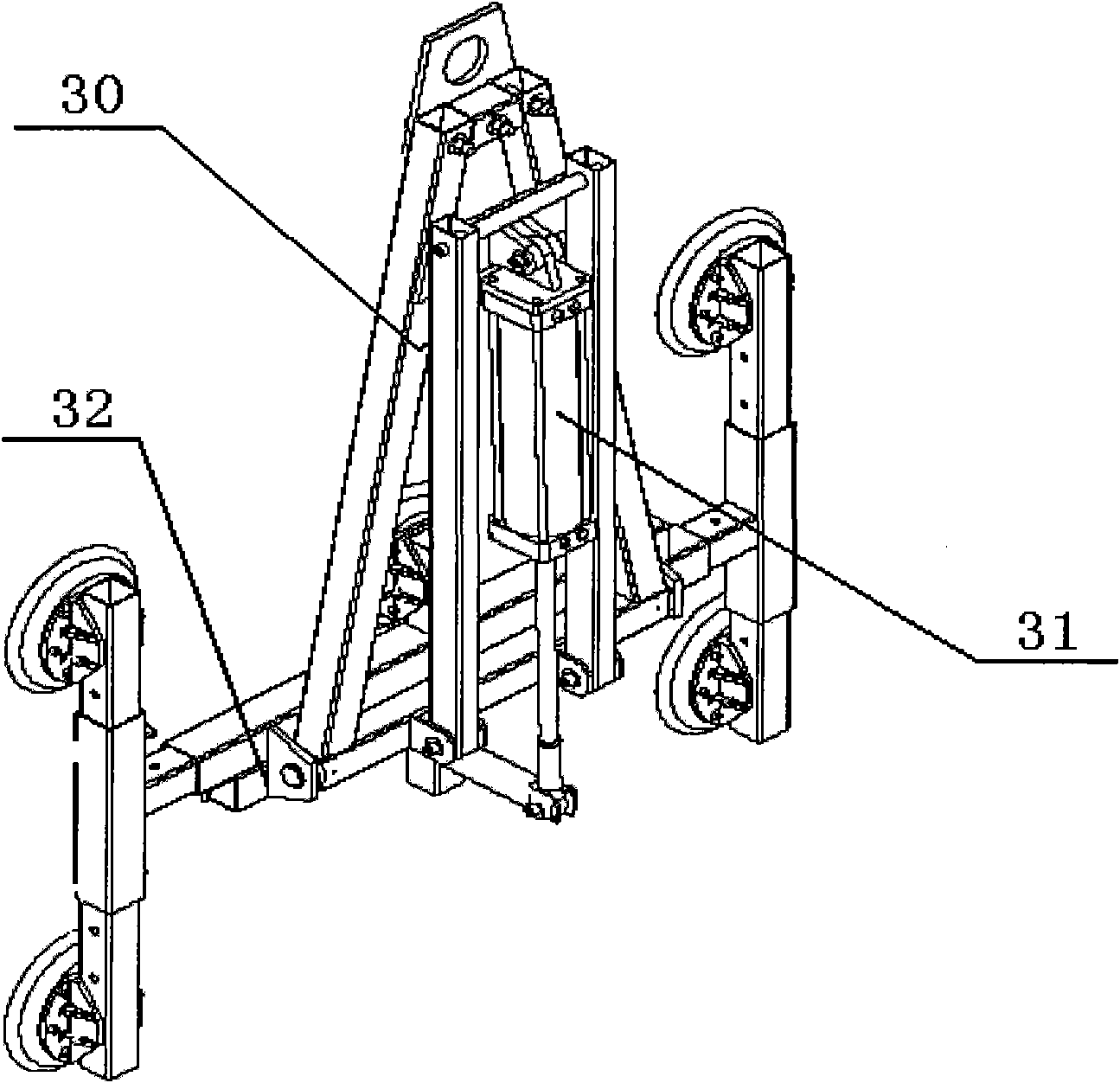

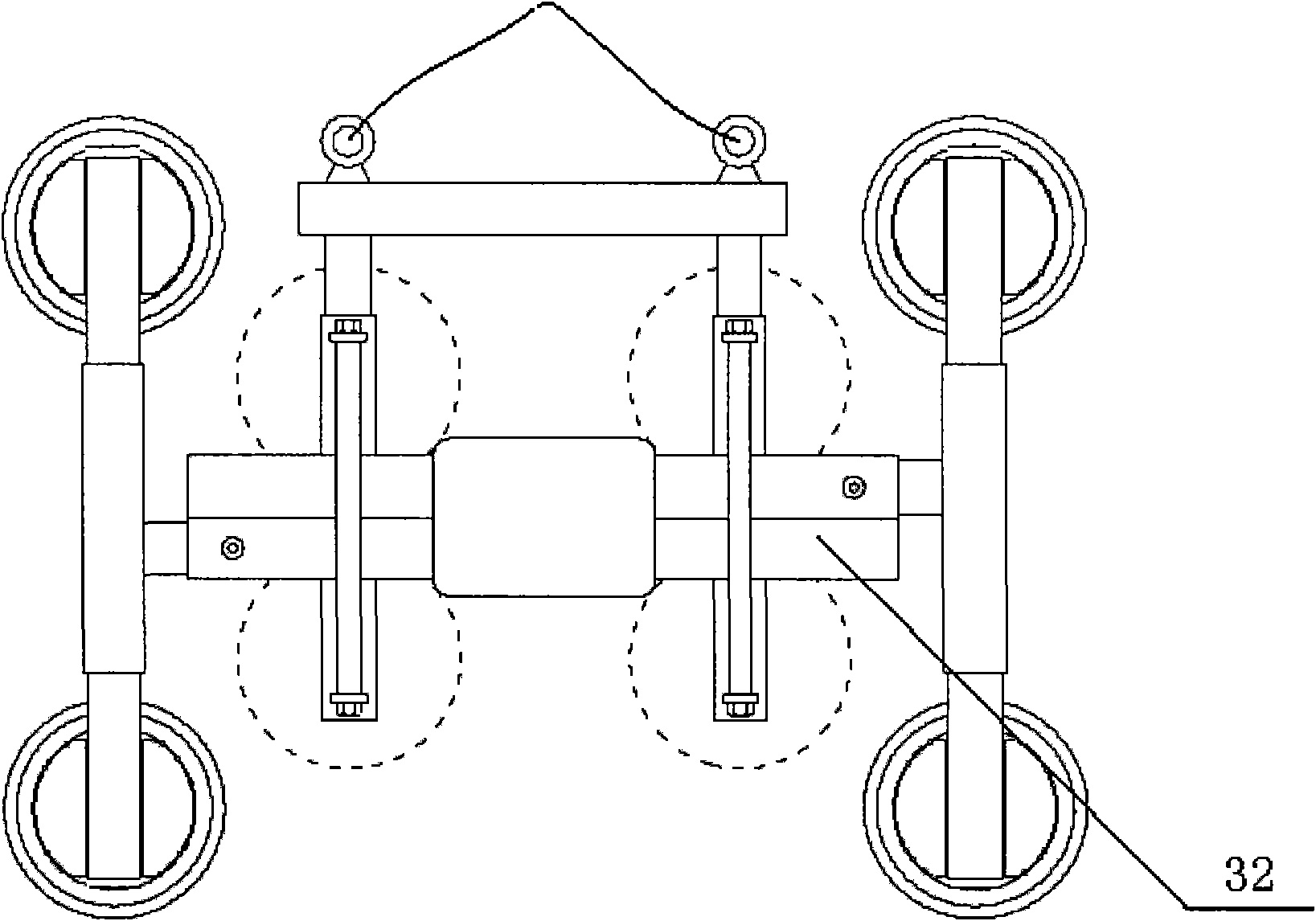

[0020] Such as Figure 4 As shown, the suction crane of the present invention includes a boom 1, and the boom 1 is connected to one end of the movable joint 2 through the boom ear climber 11, and the other end of the movable joint 2 is connected to the main frame 7; the main frame 7 is provided with a suction cup body 5 , the main frame 7 is provided with a vacuum device 4, a control device 3, and a power supply 6; a vacuum pump is arranged in the vacuum device 4, and the vacuum pump is respectively connected with the control device 3 and the air bag through a trachea; the power supply 6 is a 12V DC power supply; the vacuum device 4, the control device 3. The power supply 6 is fixed under the main frame 7 by screws; the main frame 7 is fixed with a connection plate 8, and the connection plate 8 is provided with a rotation positioning hole 9, which can be four or more t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com