Line scribing device for plate machining

A scribing device and plate processing technology, applied in the field of plate processing, can solve the problems of increased labor and time cost, large manual scribing error, slowing down plate efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

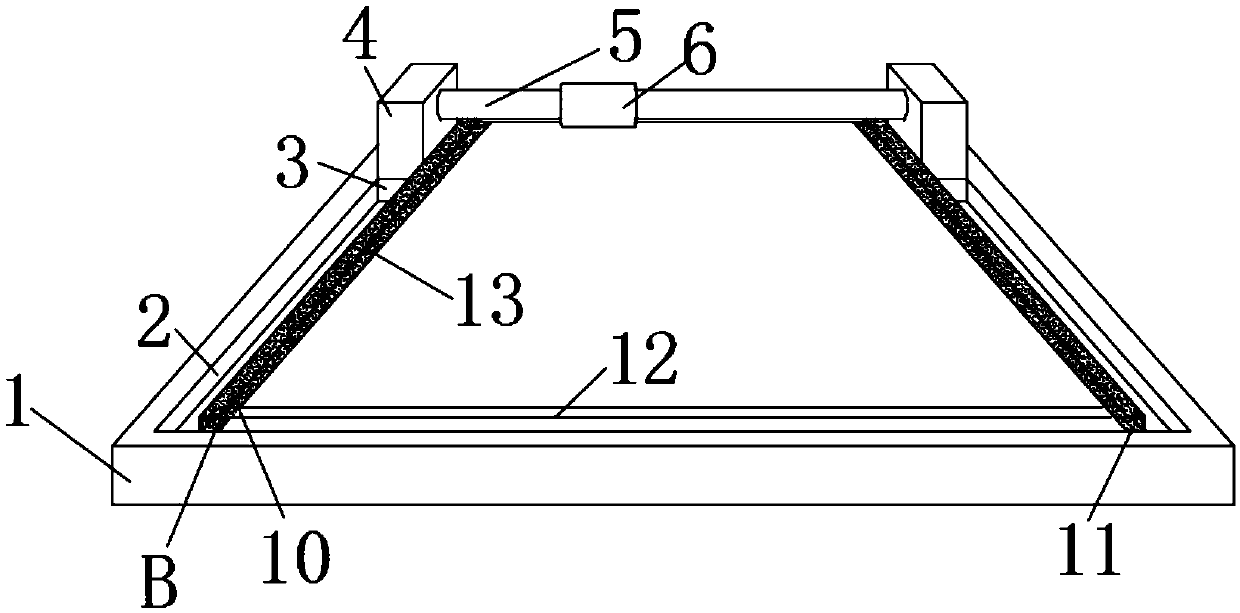

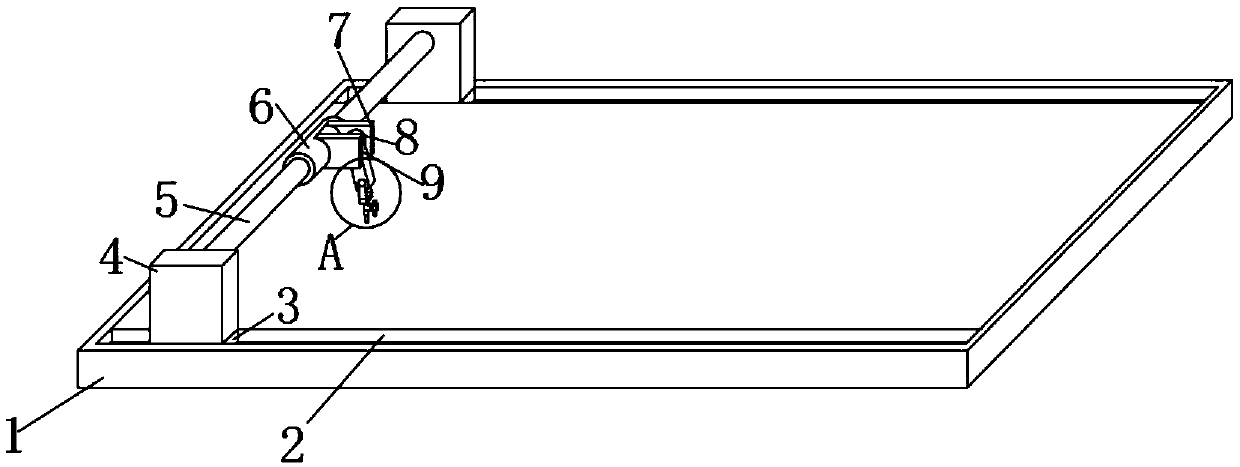

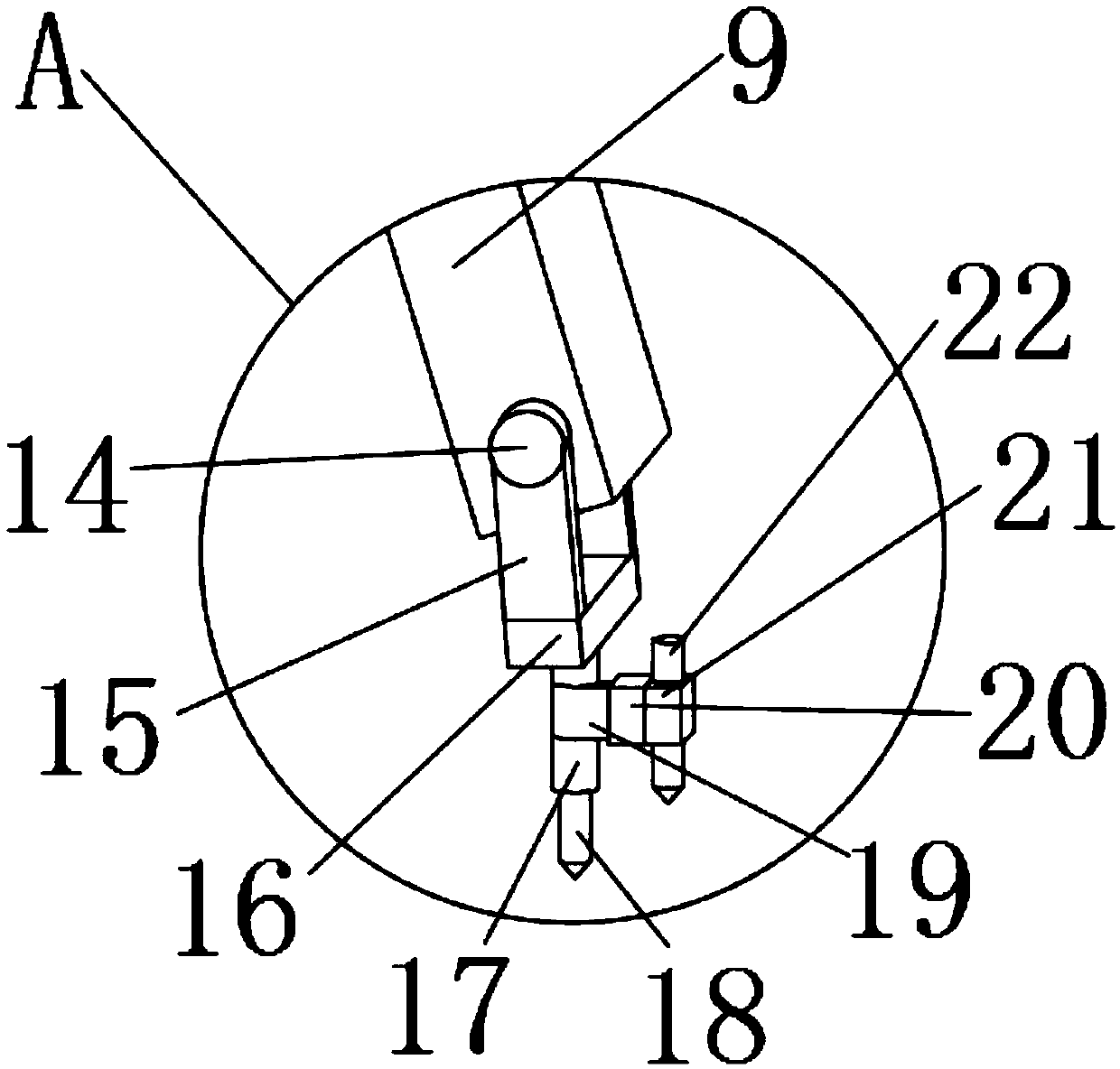

[0024] Such as Figure 1-8 As shown, the specific embodiment adopts the following technical solutions: a scribing device for plate processing, including a scribing platform 1, and slide rails 2 are connected to both sides of the scribing platform 1 away from each other, and the slide rails 2 A slide block 3 is connected inside, and one end of the slide block 3 is connected with a connecting plate 4. The connecting plate 4 is provided with a pair, and a connecting shaft 5 is connected between the opposite sides of the connecting plate 4. The connecting shaft 5 is connected with a movable column 6, and one side of the movable column 6 is connected with a pair of extension plates 7, and a rotating shaft 8 is connected between the ends of the extending plate 7 away from the movable column 6, and on one side of the rotating shaft 8 Linkage plate 9 is connected, and block 10 is fixedly connected on both sides of described marking platform 1 close to slide rail 2, and slot 11 is open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com