Round wood board marking device for wooden toy production and processing

A scribing device and log technology, which is applied in the manufacture of tools, workshop equipment, etc., can solve the problems of time-consuming and laborious, crooked line drawing, and low accuracy of manual scribing, so as to achieve a wide range of applications, improve work efficiency, and avoid scratches. The effect of line failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

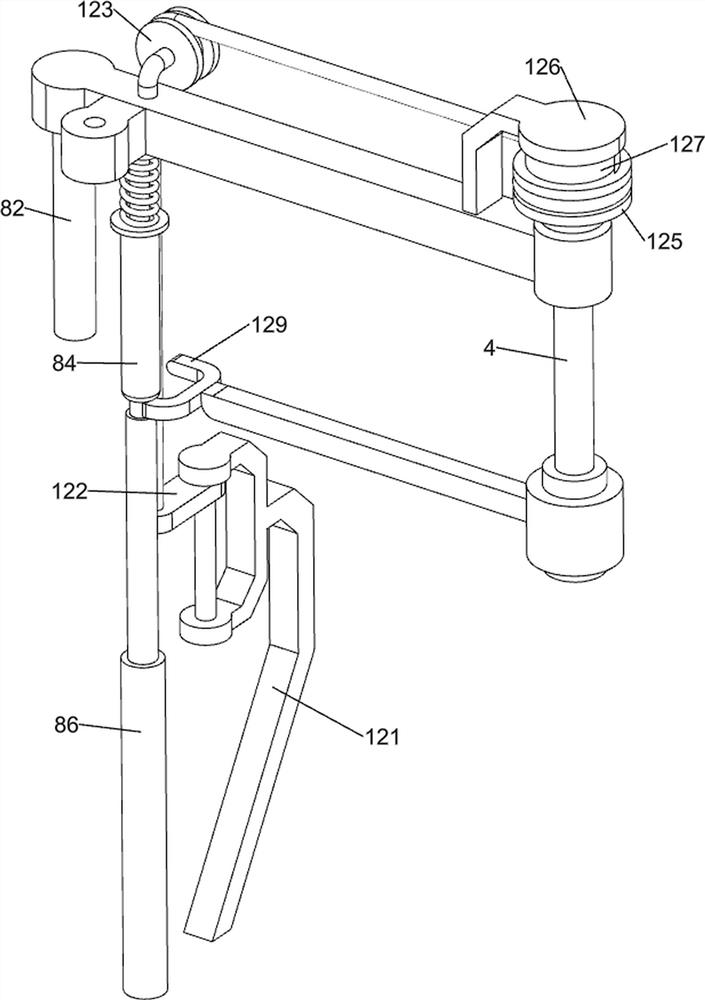

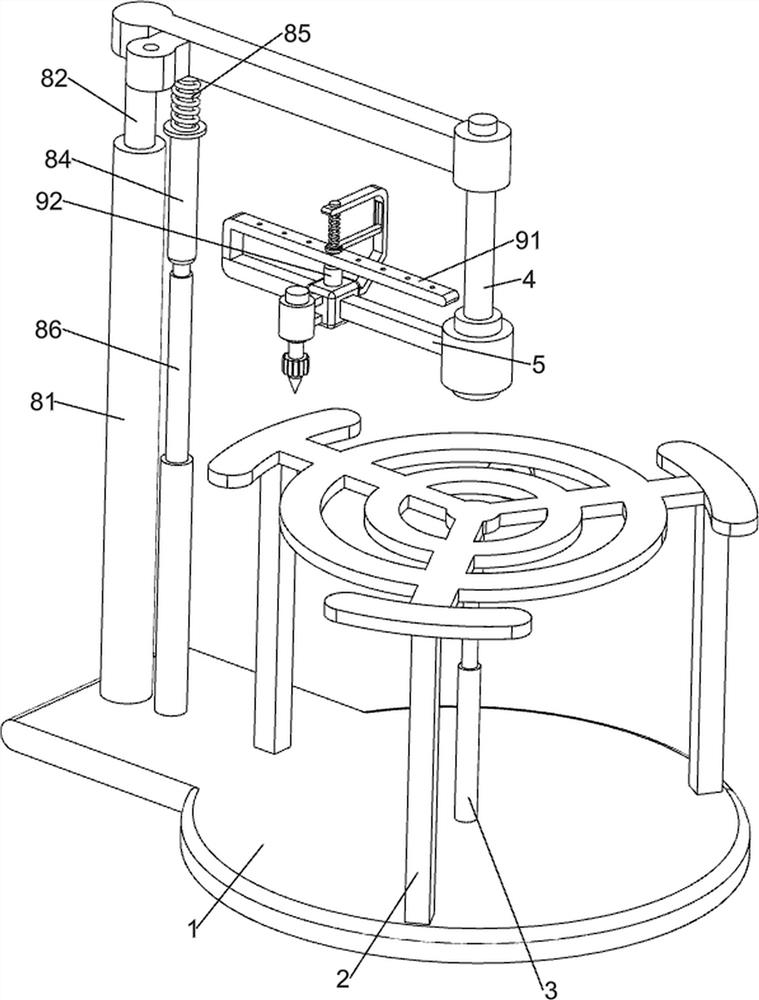

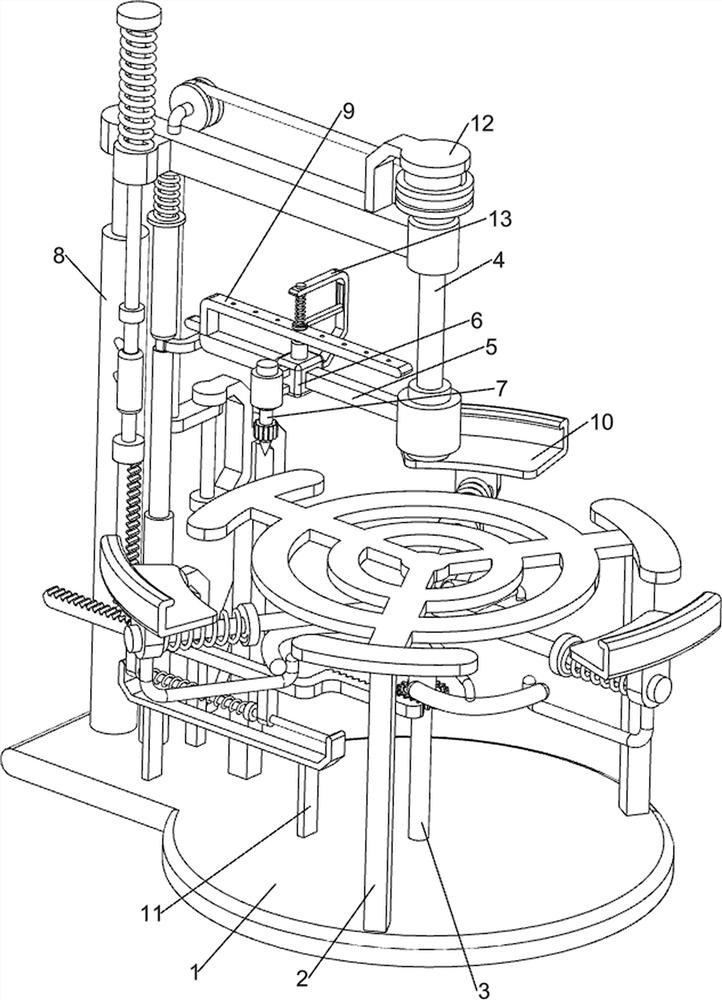

[0074] A round plank marking device for the production and processing of wooden toys, such as figure 1 , figure 2 and image 3 As shown, it includes a bottom plate 1, a workbench 2, a connecting column 3, a rotating shaft 4, a guide rod 5, a sliding seat 6, a marking knife 7, a lifting mechanism 8 and a positioning mechanism 9, and a workbench 2 is arranged on the right side of the top of the bottom plate 1. , the middle part of the right side of the top of the base plate 1 is provided with a connecting column 3, the top of the connecting column 3 is connected to the bottom of the workbench 2, the left side of the top of the base plate 1 is provided with a lifting mechanism 8, and a rotating shaft 4 is provided on a certain part of the lifting mechanism 8, Rotating shaft 4 bottoms are provided with guide bar 5, and guide bar 5 left side sliding type is provided with slide seat 6, and slide seat 6 front side is provided with marking knife 7, and guide bar 5 is provided with p...

Embodiment 2

[0079] On the basis of Example 1, such as image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a clamping assembly 10 is also included, and the clamping assembly 10 includes a mounting rod 101, a clamping plate 102, a first spring 103, a connecting rod 104, a rotating ring 105 and a special-shaped rod 106, and the upper part of the connecting column 3 is provided with a mounting Rod 101, three clamping plates 102 are evenly spaced and slidable on the outside of the mounting rod 101, a first spring 103 is provided between the inner side of the clamping plate 102 and the mounting rod 101, and connecting rods 104 are provided at the bottom of the clamping plate 102, Connecting column 3 top rotatably is provided with rotating ring 105, and rotating ring 105 is positioned at mounting rod 101 below, and rotating ring 105 outside is provided with three special-shaped rods 106 at even intervals, and special-shaped rod 106 cooperates with connecting rod 104.

[0080...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com