Device for marking color scale line of tire

A scribing device and color marking technology, applied in workshop equipment, manufacturing tools, etc., can solve the problems of poor thickness and straightness of the complementary color marking lines, unsightly manual complementary color marking lines, and lowering product grades. The line is beautiful, the grade is improved, and the effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

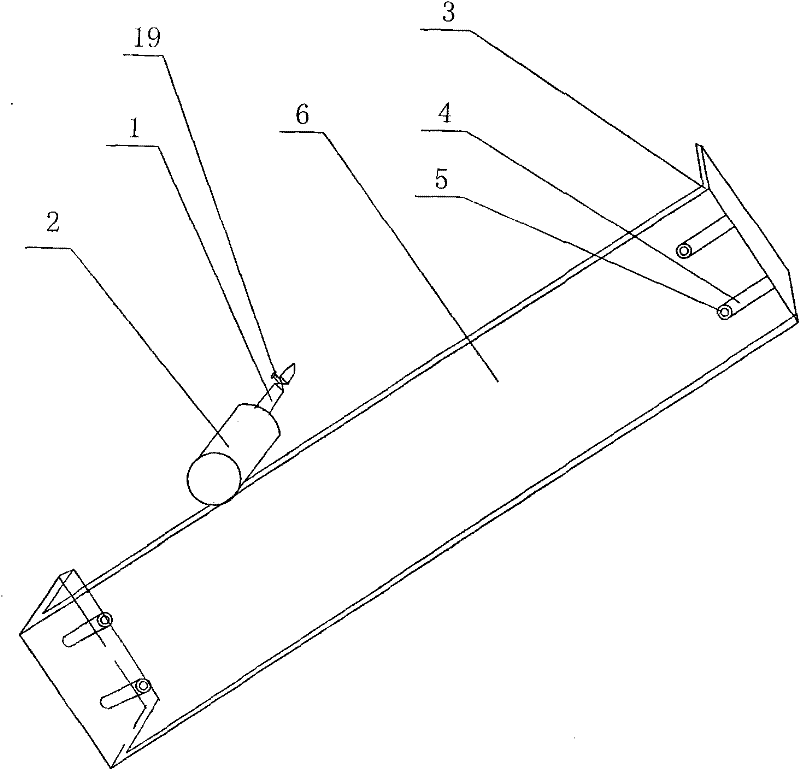

[0020] A tire color line marking device, such as figure 1 As shown, it consists of a marking needle 1, a color paste bucket 2, a splint 3, a column 4, and a bearing 5. The splint 3 has a U-shaped structure and can be made of metal, hard plastic and other materials. Two vertical columns 4 are welded opposite to each other on the inner surfaces of the two vertical plates of the U-shaped splint, and a rolling bearing 5 is installed on each of the vertical columns 4. A color paste bucket 2 is installed on one side of the bottom plate 6 of the splint 3. One end of the color paste bucket 2 is welded to the bottom plate 6, and a marking needle 1 is installed at the other end. The marking needle 1 is hollow and is connected to the color paste bucket. 2 cavities communicate. A switch 19 is provided at the end of the marking needle 1.

[0021] During the scribing operation, install an appropriate amount of color paste in the color paste bucket 2, clamp the two vertical plates of the spli...

Embodiment 2

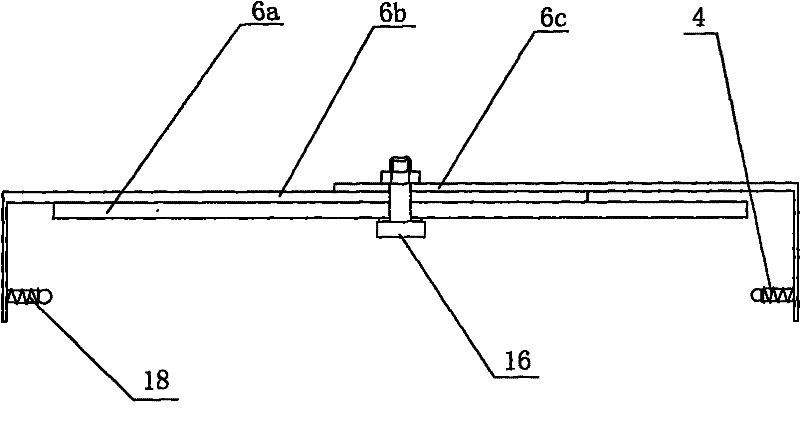

[0023] A tire color line marking device, such as figure 1 , figure 2 As shown, it is composed of a marking needle 1, a color paste barrel 2, a column 4, a bearing 5, a handle fixing plate 6a, a left width adjustment plate 6b and a right width adjustment plate 6c. The handle fixing plate 6a has a hole in the center, the left and right widening plates (6b, 6c) are both L-shaped, and U-shaped grooves are opened on the center lines of the long arms of the left and right widening plates (6b, 6c). The handle fixing plate 6a is stacked with the long arms of the left and right widening plates (6b, 6c), and bolts 16 are passed through the holes on the handle fixing plate 6a and the left and right widening plates (6b, 6c) are long. The U-shaped groove on the arm is fixed together by a nut to form a U-shaped structure. Two vertical columns 4 are welded on the inner surfaces of the short arms of the L-shaped left and right widening plates (6b, 6c) respectively, and bearings 5 are instal...

Embodiment 3

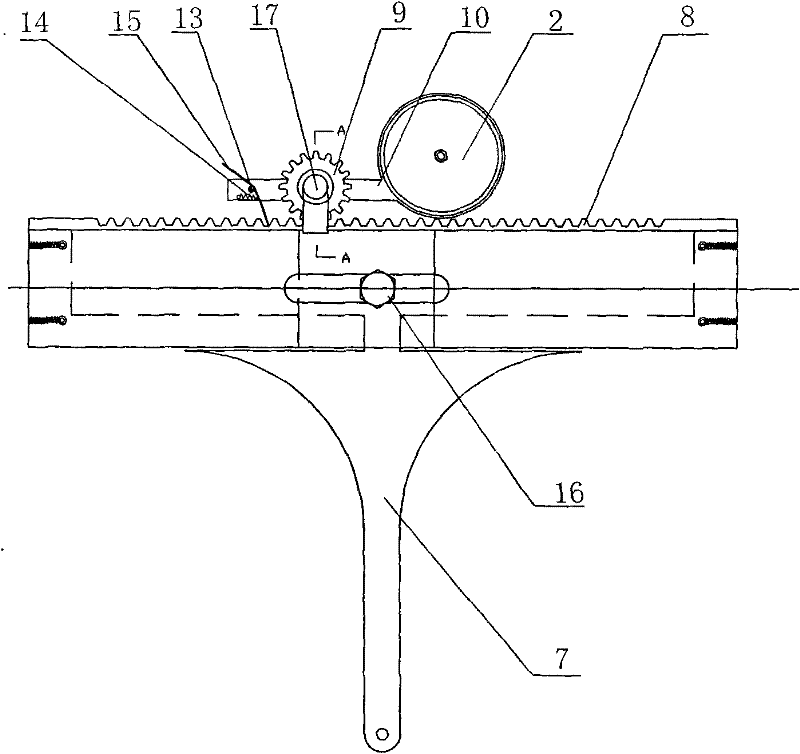

[0026] A tire color line marking device, such as Figure 1-5 As shown, it is composed of a marking needle 1, a color paste bucket 2, a column 4, a bearing 5, a handle 7, an adjustable width bottom plate, a color paste bucket position adjustment device, and a locking device. The adjustable width bottom plate includes a handle fixing plate 6a, a left width adjustment plate 6b, and a right width adjustment plate 6c, with holes in the center of the handle fixing plate 6a; the left width adjustment plate 6b and the right width adjustment plate 6c are both L-shaped, on the left U-shaped grooves are opened on the center line of the long arms of the widening plate 6b and the right widening plate 6c. The handle fixing plate 6a is stacked with the long arms of the left and right widening plates (6b, 6c). Through the holes on the handle fixing plate 6a and the slots of the long arms of the left and right widening plates (6b, 6c), the three are fixed together by nuts. The column 4 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com