Cylinder liner marking inspection template

A technology for scribing templates and cylinder liners, which is applied to workshop equipment, manufacturing tools, etc., can solve the problems of difficult position accuracy, low efficiency, and low success rate, and achieve the effect of convenient and intuitive detection of the position of each hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

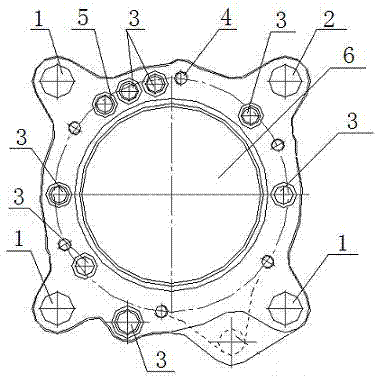

[0010] Such as figure 1 As shown in the cylinder liner marking inspection sample, there are three bolt holes 1 and one positioning bolt hole 2 on the four corners of the marking sample, the inner hole 6 of the cylinder liner is arranged in the middle, and three Adjacent to the water holes 3, two water holes 3 are provided at both ends of the horizontal center line of the marking plate, two water holes 3 are respectively provided at the lower part of the upper right corner of the marking plate and the upper part of the lower left corner of the marking plate, and the lower left of the marking plate The right side of the corner is provided with a water hole 3, six threaded holes 4 are arranged on the circumference outside the cylinder liner inner hole of the marking model, and a sealing ring groove 5 is arranged outside the water hole. The cylinder liner marking model of the present invention, Locate with φ265 holes, carve out the positions of each hole according to the coordinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com