Measuring tool for detecting spiral lift of vibration absorber spring seat

A spring seat and shock absorber technology, which is applied to measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of difficult positioning of the spring seat, inaccurate measurement, and the inability of online inspection and batch inspection of the spring seat, so as to solve the problem of difficult positioning. , Easy to use, solve the effect of online inspection and batch inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

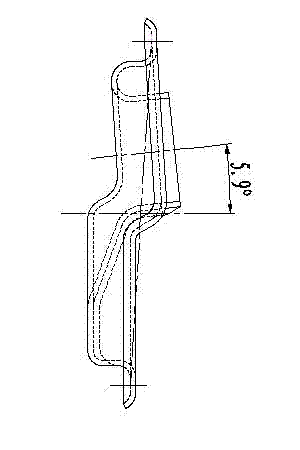

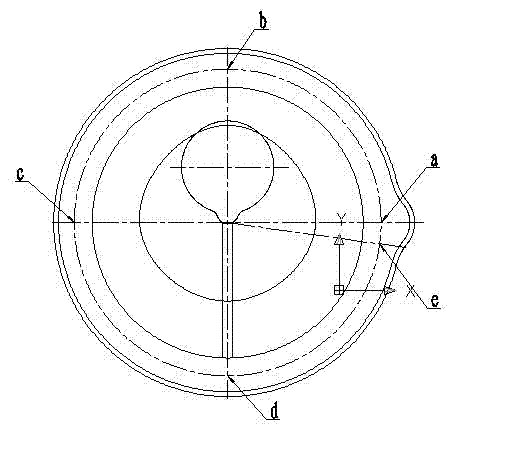

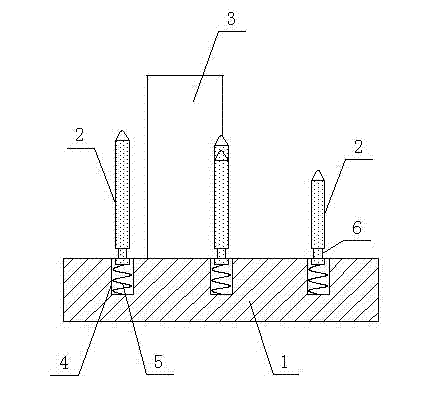

[0023] Embodiment one: if image 3 As shown, a shock absorber spring seat spiral lift detection measuring tool includes a base 1, and the base 1 is provided with a standard seat 3 and several measuring columns 2 that can be stretched up and down. The corresponding fixed column, the measuring column 2 is connected to the base 1 through the spring 5, the base 1 is provided with a spring 5 hole 4, the spring 5 is located in the spring 5 hole 4, the elastic force of the spring 5 is greater than the weight of the spring 5 seat, the spring 5 The upper end is connected with the measuring column 2, and the lower end is connected with the spring 5 hole 4 of the base 1.

[0024] The present invention determines the height dimension of each measuring column 2 according to the relative position distance of each lift point of the 5 spring seats, that is, the surface connected by the vertices of each measuring column 2 is the helical lift surface of the 5 spring seats. During detection, th...

Embodiment 2

[0025] Embodiment two: if Figure 4 As shown, the measuring column 2 in this embodiment is composed of an external casing 21 and a telescopic column 22 inside the casing 21, the casing 21 is fixedly connected to the base 1, and the telescopic column 22 is connected to the casing 21 through a spring 5 , the elastic force of the spring 5 is greater than the weight of the spring 5 seat, the upper end of the spring 5 is connected with the measuring column 2, and its lower end is connected with the casing 21, and the lower tolerance position of the tolerance zone 6 of the side wall of the measuring column 2 is flat with the upper surface of the casing 21 together. The remaining structures and usage methods of this embodiment are the same as those in Embodiment 1. During testing, each measuring column 2 is just in contact with the spring 5 seat. It is judged as qualified, and when it is outside the tolerance zone 6 of the measuring column 2, it is judged as unqualified.

Embodiment 3

[0026] Embodiment three: as Figure 5 As shown, the difference from Embodiment 1 is that a measuring seat is added above the base 1 in this embodiment, the standard seat 3 and the measuring column 2 pass through the measuring seat, and the measuring column 2 can be moved up and down relative to the measuring seat telescopic, a backing plate 7 is provided between the measuring seat and the base 1, and they are fixed together by screws 8 passing through the base 1, the backing plate 7 and the measuring seat in sequence, and the lower tolerance position of the tolerance zone 6 of the side wall of the measuring column 2 is the same as The upper surface of the measuring base is even, and a stop step 9 is provided on the part of the measuring column 2 below the measuring base, so as to ensure that the protruding height of the measuring column 2 remains unchanged. The method of use of this embodiment is the same as that of the previous two embodiments. During detection, each measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com