Wobbler crisscross line scribing method

A plum blossom head and word line technology, which is applied in the field of plum blossom head well-tac-toe line marking method, can solve the problems of poor workpiece division, increased process cost, and impact on assembly and use, so as to reduce production costs, save sample costs, and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

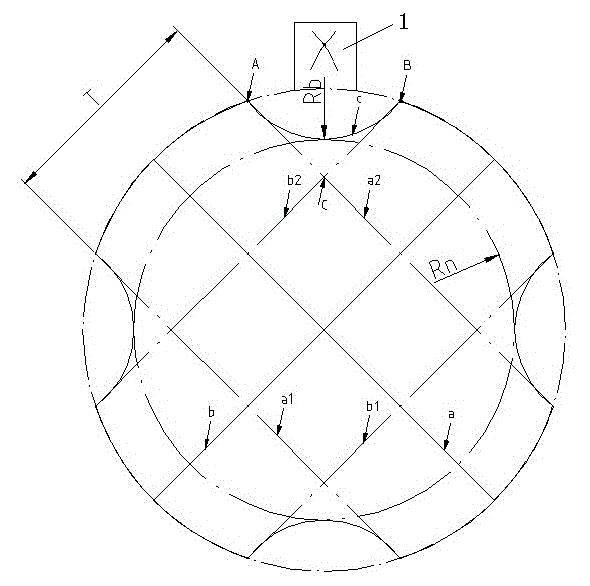

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0015] According to the design requirements of the roll torx head processing drawings: the inscribed circle radius Rn of the torx head cut arc and the radius Rb of the torx head cut arc are known.

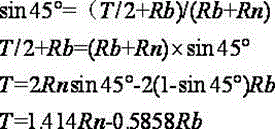

[0016] According to the tangent between the grid line and Rb, it can be concluded that:

[0017]

[0018] According to the formula obtained above, the value of the width T of the plum blossom head is calculated according to the functional relationship between the radius Rb of the cut arc of the plum blossom head and the radius Rn of the inscribed circle Rn of the cut arc of the plum blossom head designed on the drawing; Mark two centerlines a and b perpendicular to each other on the end surface of the head; use a scribe gauge to draw on the end surface of the torx head with the two centerlines a and b as the reference, parallel to the two centerlines a and b and The fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com