Yoke assembly for moving iron loudspeakers or receivers

A loudspeaker and receiver technology, which is applied in the fields of electroacoustics and micromechanics, can solve the problems of restricting the development of related moving iron speakers and receivers, complicating the manufacturing process, and weakening the competitive advantage, so as to achieve simple manufacturing process and improve the magnetic circuit structure , The effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and a preferred embodiment.

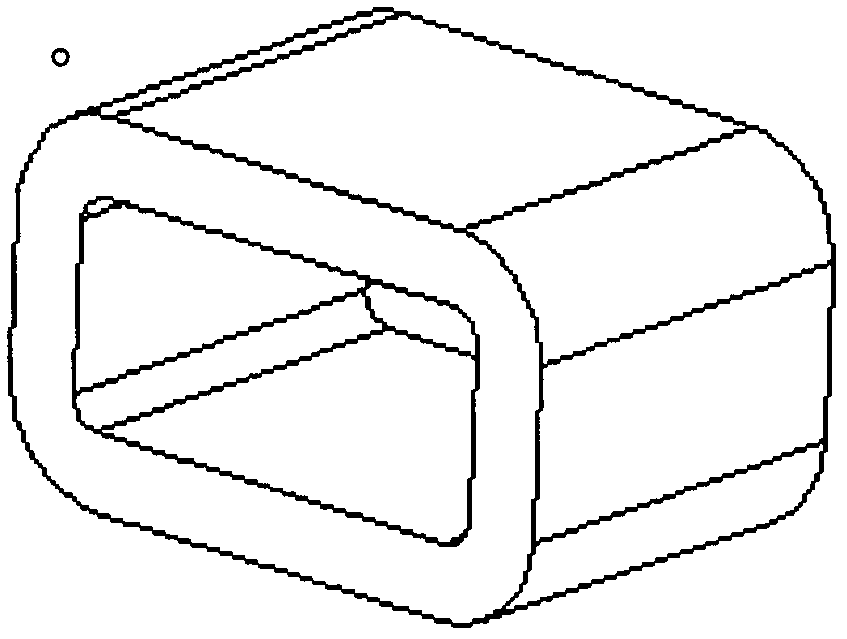

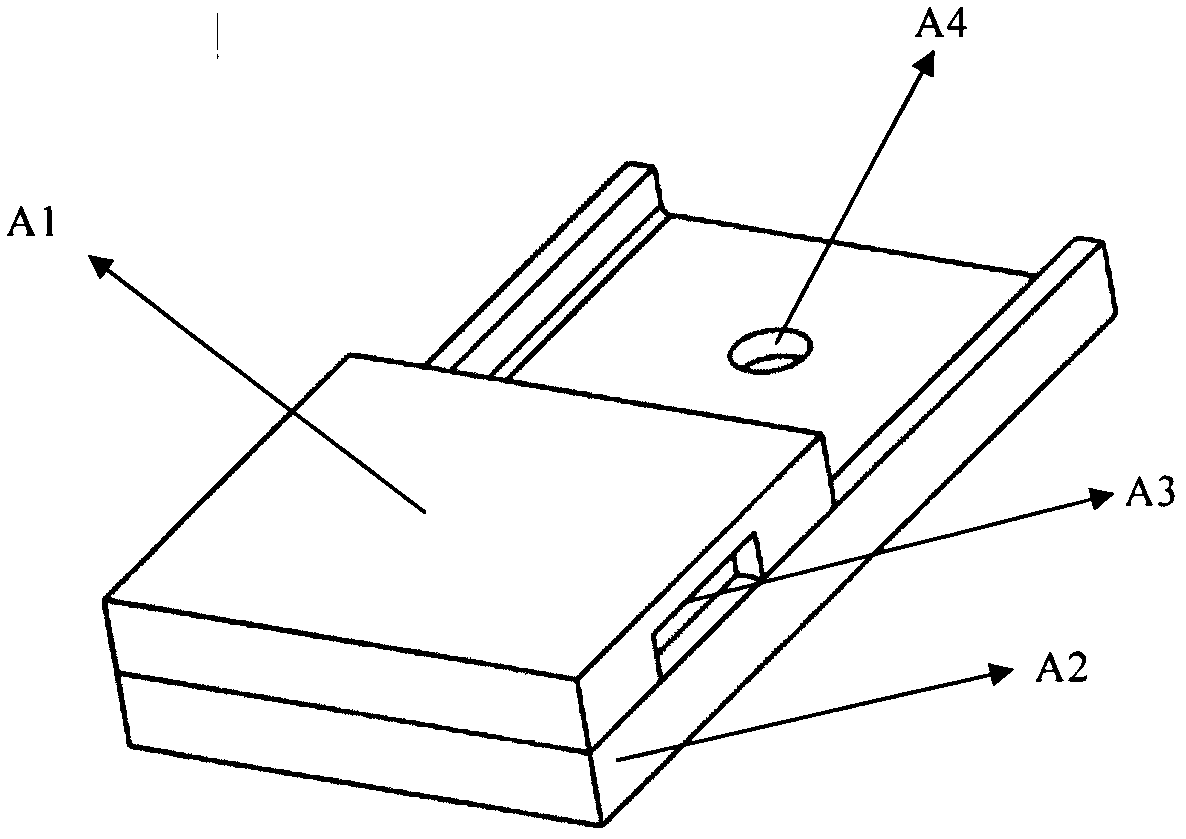

[0023] refer to Figure 3-5 , this embodiment relates to a yoke device B1 for a moving iron speaker or receiver, the yoke device B1 is a two-piece structure, comprising an upper part A1 and a lower part A2; the yoke device B1 has a Part A1 is a semi-box structure surrounded by four sides, and an opening groove A3 is placed on one side of the upper part; the lower part A2 of the yoke device B1 is also a semi-box structure surrounded by four sides structure, a through hole A4 is provided on the bottom surface of the lower part A2.

[0024] When in use, the upper part A1 and the lower part A2 of the yoke device B1 are aligned according to the edges and fixedly connected to form a yoke device B1 enclosed by the front end. In this embodiment, the combination of the upper part A1 and the lower part A2 of the yoke device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com