An upward hanging type downhole oil-water separation pipe string

A technology of oil-water separation and oil-water separator, which is applied in wellbore/well components, measurement, production fluid, etc. It can solve problems such as difficult water injection control, high implementation risk, and complex string structure, and achieve breakthrough in size limitation and applicable Effects with a wide range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

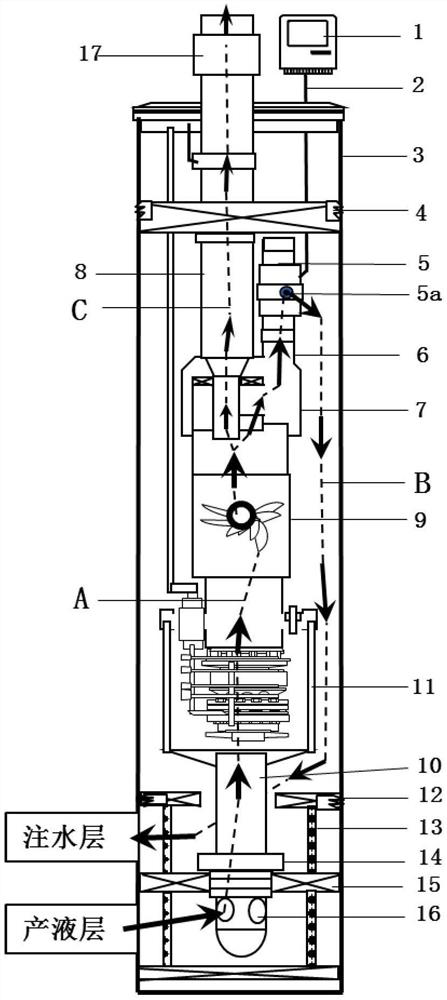

[0019] see figure 1 , an upwardly suspended downhole oil-water separation and measurement and adjustment string, including a perforated pipe 16 connected by oil pipes from bottom to top, an insertion seal 14, a canned pump system 11, a downhole oil-water separator 9, and a downhole oil-water separator. The upward suspension type separating mechanism 7 that separator 9 is connected. The separation mechanism 7 is a three-way structure, the upper end of which is two ports, the first port is connected to the lifting oil pipe 8, the second port is connected to the return oil pipe 6, and the lower port is connected to the outlet of the downhole oil-water separator, forming an upward hanging structure.

[0020] The insertion seal 14 is inserted in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com