Preparation method of sintered neodymium-iron-boron magnet

A neodymium iron boron and magnet technology, used in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of easy agglomeration of magnetic powder, limited diffusion depth, uneven distribution of heavy rare earth elements, etc., to reduce magnetization coupling The effect of suppressing uneven distribution of heavy rare earths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

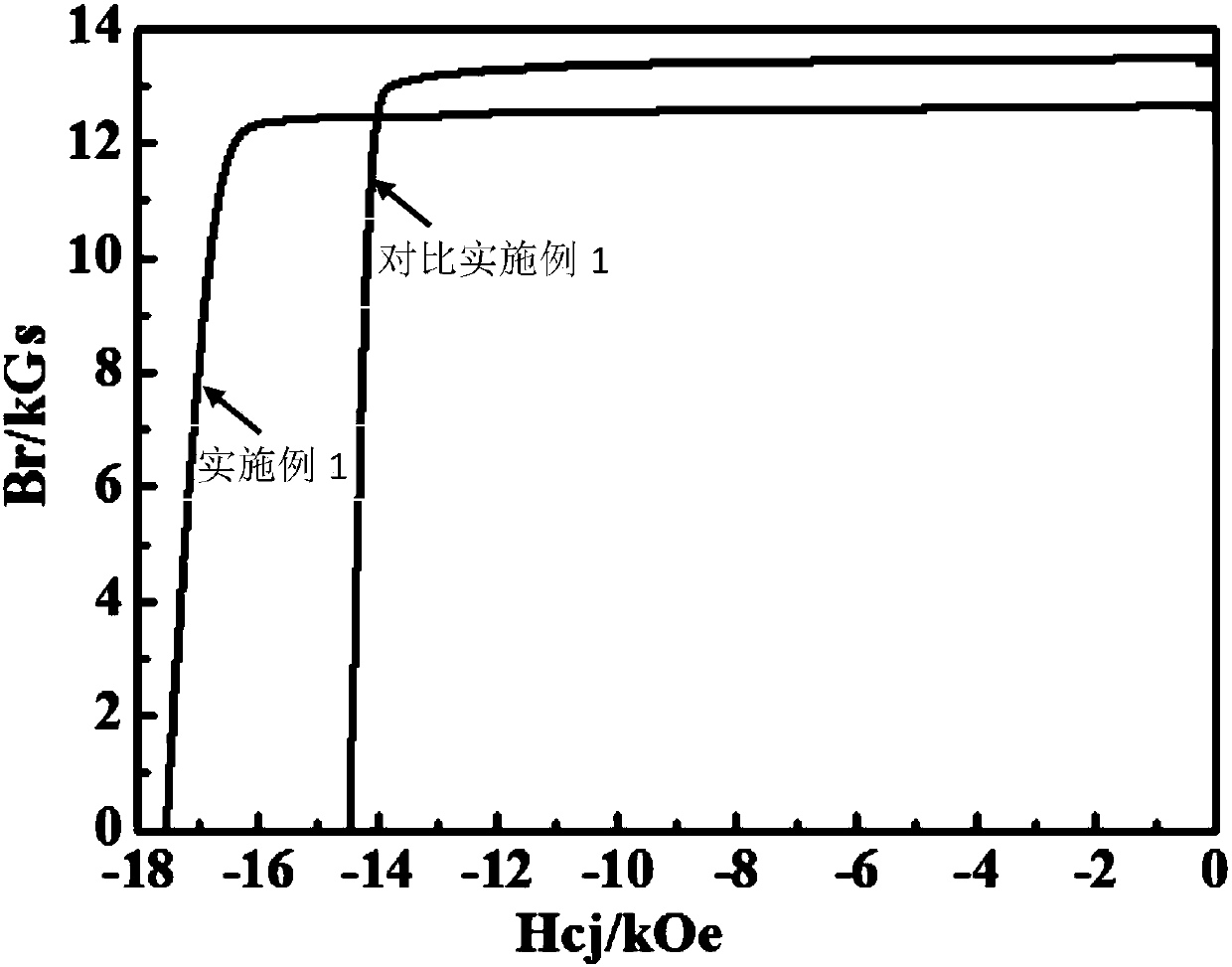

Embodiment 1

[0029] In this embodiment, the preparation process of the sintered NdFeB magnet is as follows:

[0030] (1) Quick-setting: NdFeB Nd is prepared by mixing and melting raw materials and casting copper rollers 33 Fe bal B 0.95 Cu 0.2 For the quick-setting sheet, the copper roller rotates at a speed of about 1.4m / s, and the thickness of the obtained quick-setting sheet is about 300μm.

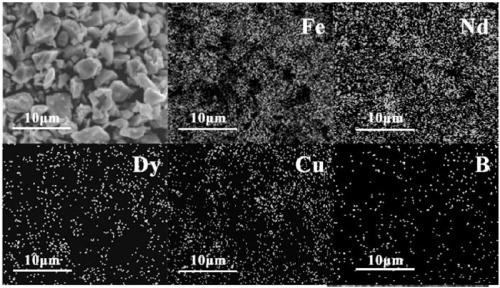

[0031] (2) Powder making: hydrogen crush the quick-setting tablet into NdFeB alloy powder with an average particle size of 0.1mm-1mm, and then use the hydrogen crushing process to make the powder into magnetic powder with an average particle size of about 2.0 μm.

[0032] (3) Mixing: dissolving the heavy rare earth organic compound in an organic solvent and ultrasonically dispersing it to obtain a mixture. The heavy rare earth organic compound is dysprosium isopropoxide, and the organic solvent is absolute ethanol. Then mix the mixture with the magnetic powder prepared in step (2), stir evenly...

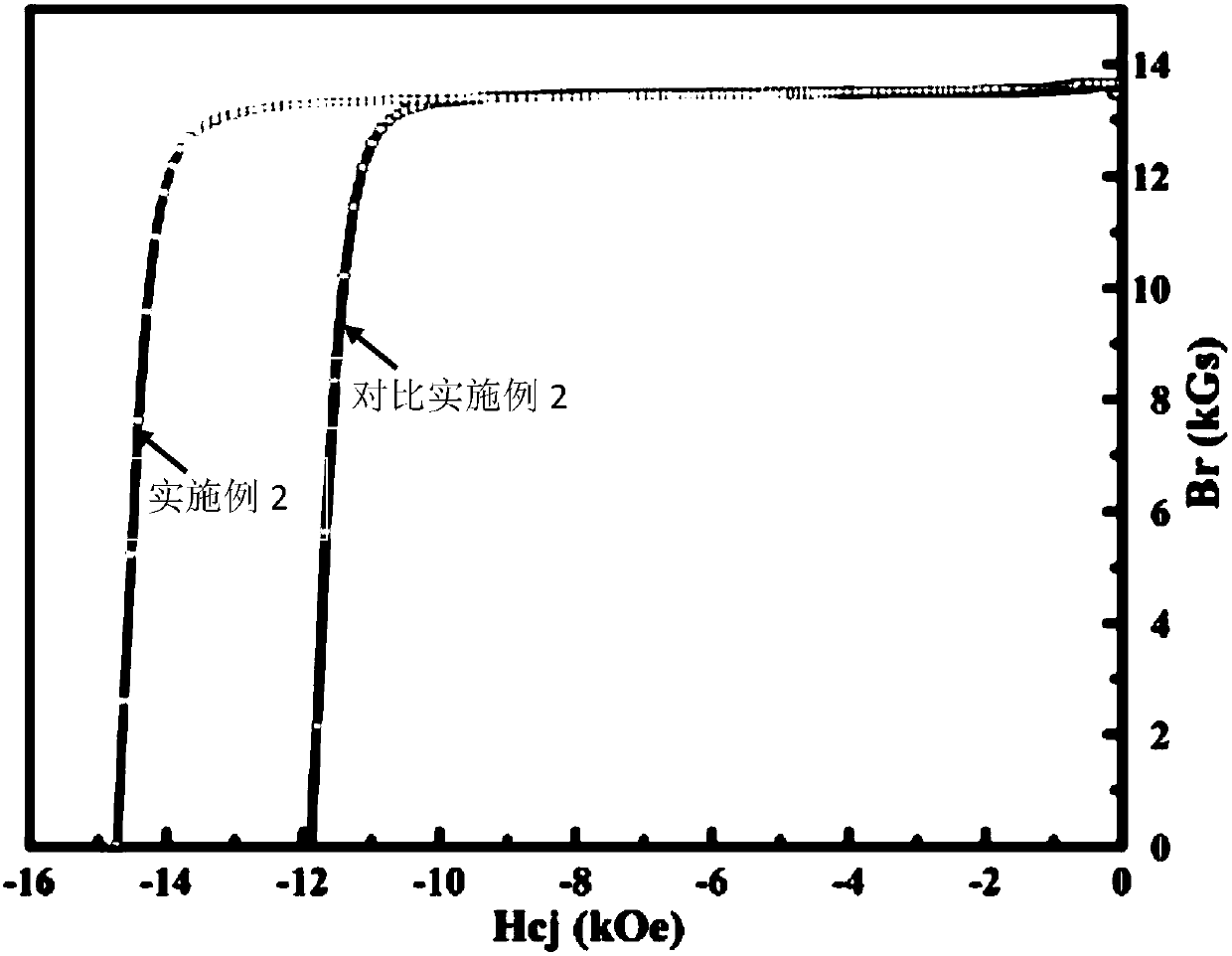

Embodiment 2

[0048] In this embodiment, the preparation process of the sintered NdFeB magnet is as follows:

[0049] (1) Quick-setting: NdFeB (Pr 0.2 Nd 0.8 ) 30.5 Al 0.2 Cu 0.04 Fe bal B 1 For the quick-setting sheet, the speed of the copper roller is about 1.4m / s, and the thickness of the obtained quick-setting sheet is about 300μm.

[0050] (2) Powder making: hydrogen crush the quick-setting tablet into NdFeB alloy powder with an average particle size of less than 1 mm, and then use the hydrogen crushing process to make the powder into a powder with an average particle size of about 3 μm.

[0051] (3) Mixing: Under an anhydrous and oxygen-free environment, dissolve the heavy rare earth halide in an organic solvent to obtain a solution with a concentration of 2 g / L. The heavy rare earth halide is terbium chloride, and the organic solvent is absolute ethanol. Then mix the solution with the magnetic powder prepared in step (2), disperse evenly by ultrasonic, wherein the heavy rare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com