Lanthanum titanate-based glass sheet as well as preparation method and application of lanthanum titanate-based glass sheet

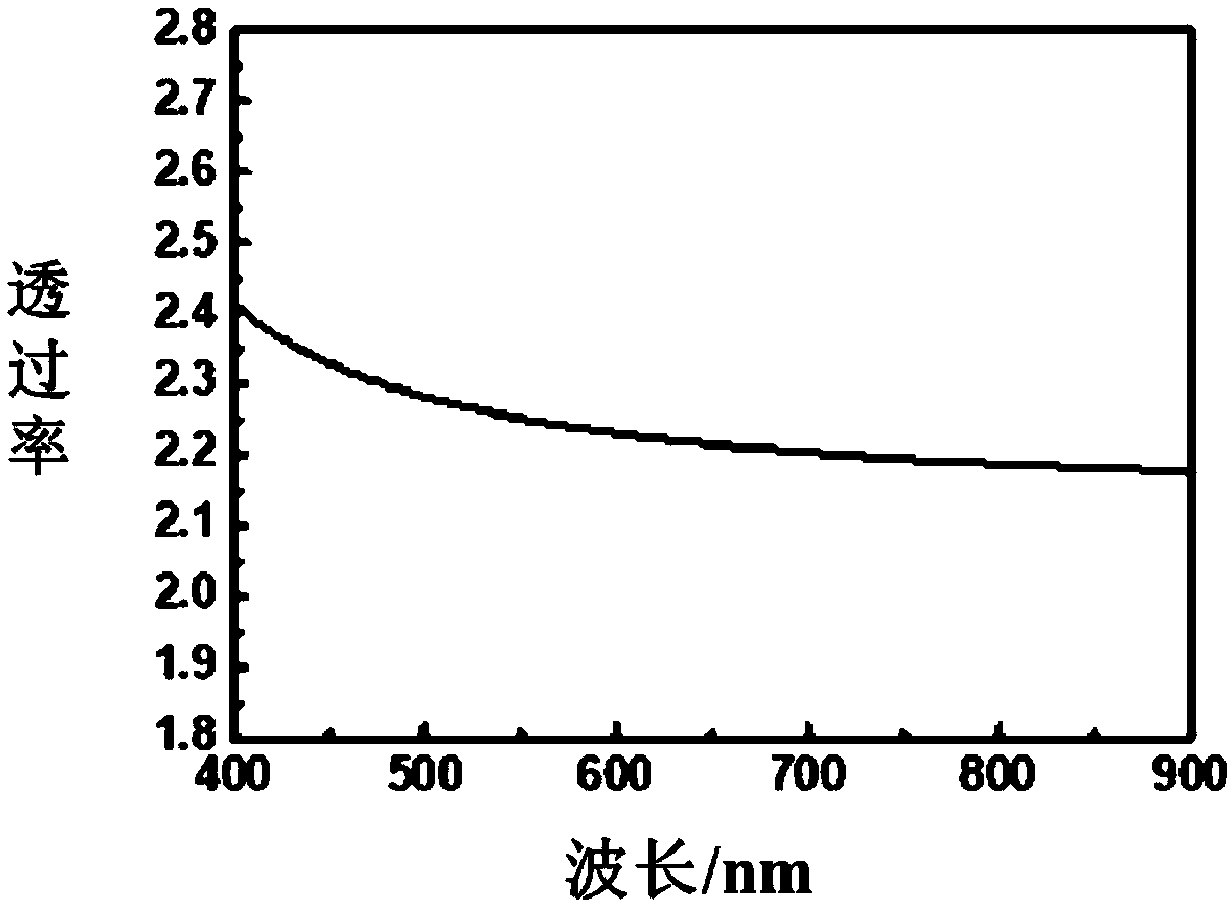

A technology of glass flakes and lanthanum titanate, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of increasing the crystallization activation energy of samples and complex glass network structure, so as to preserve optical properties and increase power The effect of optical window and excellent optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

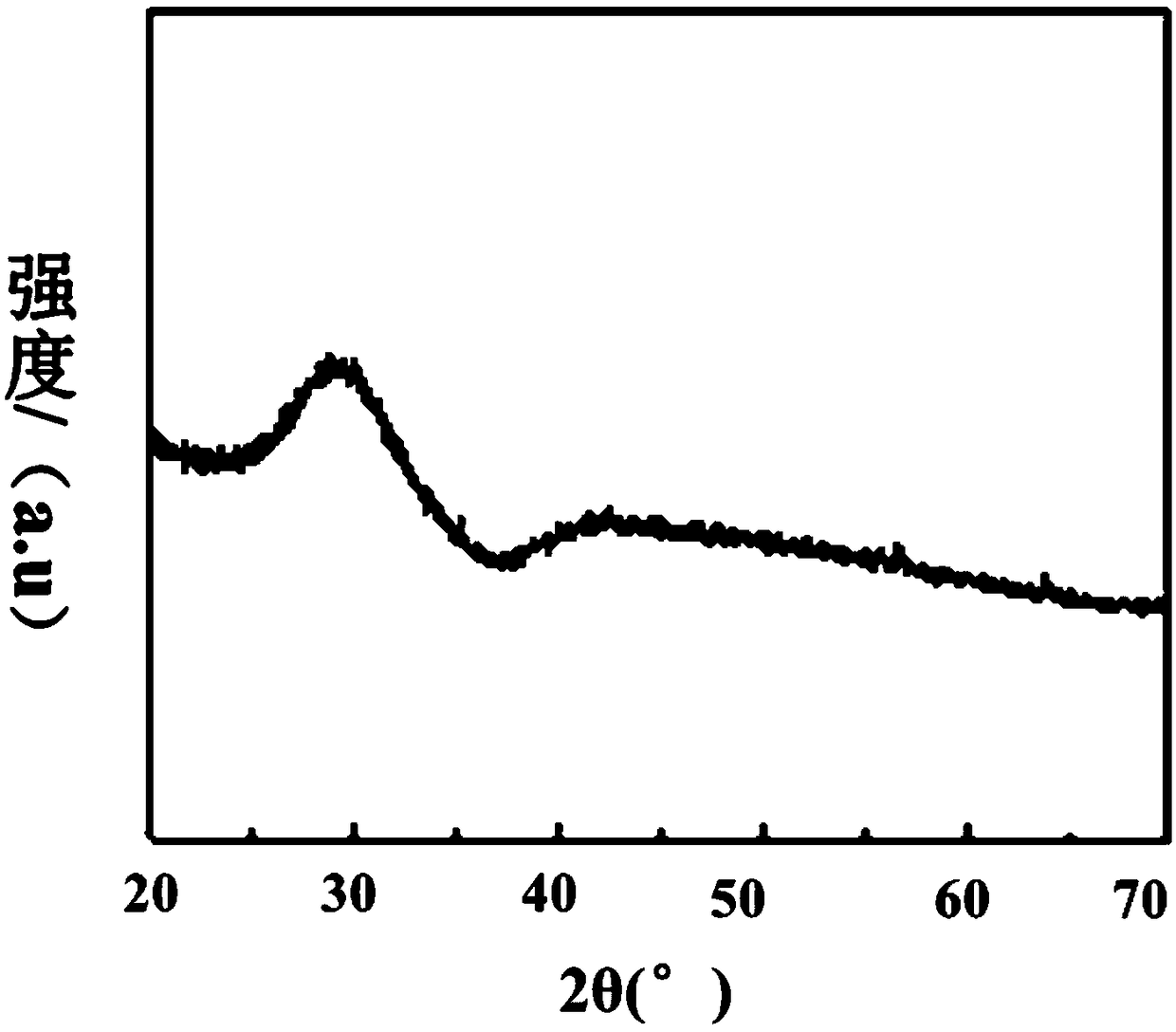

[0079] (1) Raw material powder La 2 o 3 、TiO 2 and silicon oxide by LaO 3 / 2 :TiO 2 : The silicon oxide molar ratio is 30.8:59.2:10.0, weighed, mixed evenly, and calcined at 1200°C for 2 hours. The calcined powder was pressed into a block under a pressure of 10 MPa, and then divided into 40 mg container-free solidified raw material;

[0080] (2) Pneumatically suspend the non-container solidified raw material in oxygen to make it stably suspended in the air, semiconductor laser and CO 2The laser is heated to 2200°C at the same time to make the non-container solidified raw material into a molten state for 2 minutes, and then cooling at a cooling rate of 300°C / s to obtain glass pellets with a diameter of 3mm;

[0081] (3) After crushing the glass balls, glass powder with a particle size of 50 μm was obtained. Under vacuum conditions, the glass powder was placed in a graphite mold with a diameter of 20 mm, and the temperature was raised to 860 ° C at a heating rate of 10 ° C / ...

Embodiment 2

[0084] The difference with Example 1 is that in step (1) LaO 3 / 2 :TiO 2 :SiO2 2 The molar ratio is 27.4:52.6:20.

Embodiment 3

[0086] The difference with Example 1 is that in step (1) LaO 3 / 2 :TiO 2 :SiO2 2 The molar ratio is 32.5:62.5:5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com