A kind of sheet-like hydrogel material and preparation method thereof

A hydrogel and sheet technology, applied in the chemical field, can solve the problems of inconvenient movement, inability to prepare, and high fluidity, achieve high biocompatibility and safety, avoid uneven sheet thickness, and improve material liquid The effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

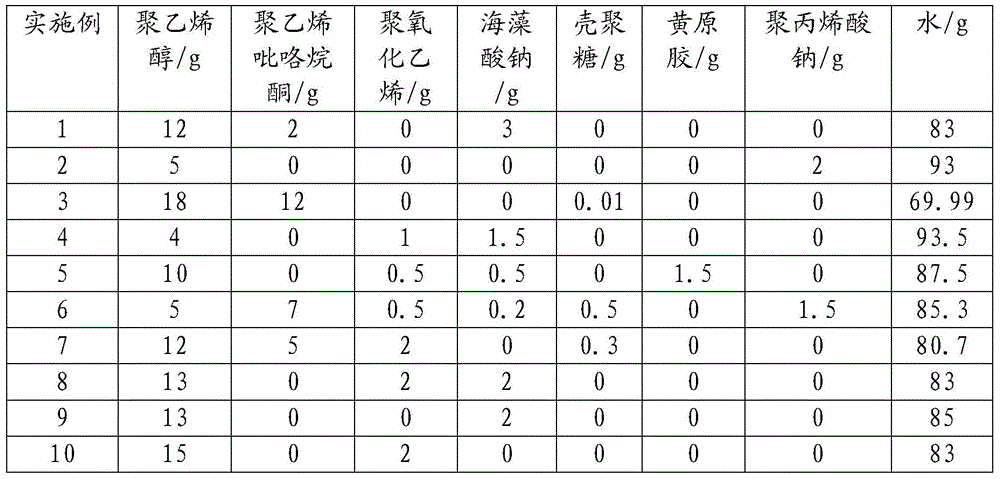

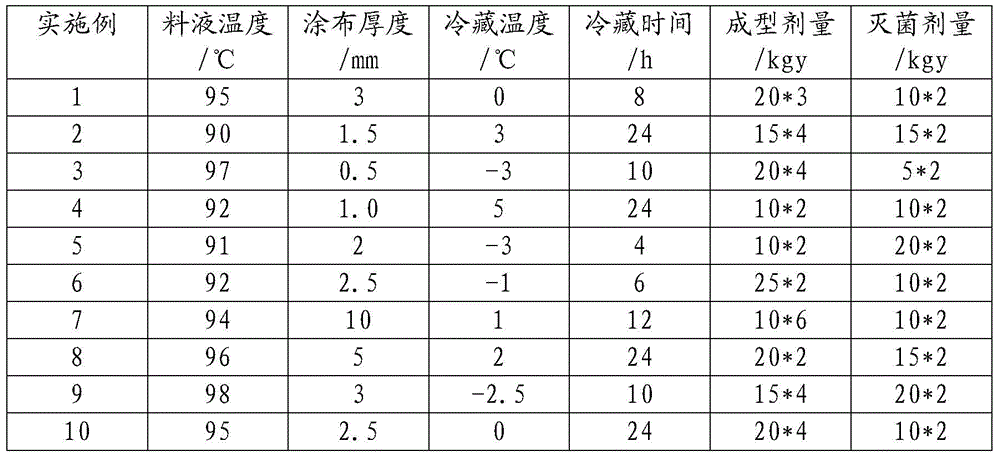

[0033] According to the components in Table 1, put the raw materials into the reaction equipment with stirring and heating functions, according to the process parameters given in the attached table 2, the reaction equipment is heated to 95 ° C and stirred until the feed liquid is a transparent, viscous solution, Transfer the material liquid to the material cylinder and place it. After the temperature of the material liquid drops to 20°C, the material liquid is applied between the two layers of release films through the coating equipment, and the coating thickness is 3 mm. The obtained sheet was refrigerated in a refrigerating device, the refrigerating temperature was 0 °C, and the refrigerating time was 8 h, the sheet was pre-formed, and the pre-formed sheet was irradiated by an electron accelerator. The irradiation times were 3 times, the radiation-formed sheet was cut, packed into a package, and sterilized by radiation. The sterilization dose was 10 kGy each time, and the irr...

Embodiment 2-10

[0039] According to the method described in Example 1, the hydrogel sheet was prepared according to the material liquid formula given in Table 1 and the synthesis process parameters given in Table 2, respectively, to obtain the hydrogel sheet.

[0040] The sheet-like hydrogel materials prepared according to Examples 1-10 all have the following performance characteristics: the water content reaches 65%-90%, the visible light transmittance is more than 80%, the cytotoxicity is less than or equal to grade 2, and there is no skin irritation. No skin sensitization, the difference in sheet thickness is less than or equal to 0.05mm, and can be used in the production of wound care dressings and beauty care products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com