Circular rail shot blasting robot for polishing large-sized workpiece

A circular track and large-scale workpiece technology, which is applied in the direction of abrasive jet machine tools, manufacturing tools, metal processing equipment, etc., can solve the problems that it is difficult to find shot blasting equipment, the size of workpieces is limited, and large workpieces cannot be processed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better illustrate the present invention and facilitate understanding of the technical solutions of the present invention, typical but non-limiting examples of the present invention are as follows.

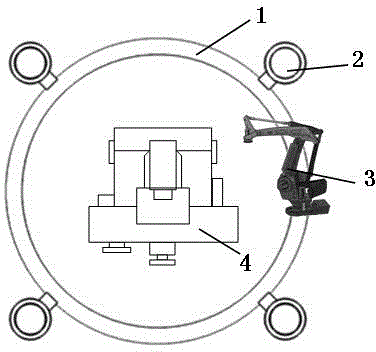

[0015] A circular track shot peening robot for polishing large workpieces mentioned in the content of the present invention is described with reference to the drawings, which is used for processing large aluminum castings.

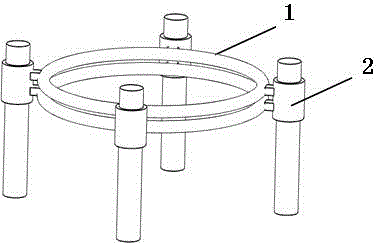

[0016] The workpiece size is about 2×2×1m. There are 4 uprights with a diameter of 0.1m and a height of 2.5m. The diameter of the circular track is 3m.

[0017] The robot body uses Nachi SRA100 robot, with a maximum working radius of 2.6m, a maximum load of 100kg, and a repeat positioning accuracy of 0.1mm. The control system adopts the FD11 control system of Japan OTC (Ou Di Xi).

[0018] A small shot blasting machine is installed on the mechanical arm, and a shot blasting shielding device is attached around the nozzle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com