Method for cutting brittle material substrate

A brittle material substrate and substrate technology, applied in stone processing equipment, glass cutting devices, fine working devices, etc., to achieve the effect of improving the quality of the end surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Although the cutting method of the brittle material substrate of the present invention will be described in detail below, the present invention is not limited to these implementation forms.

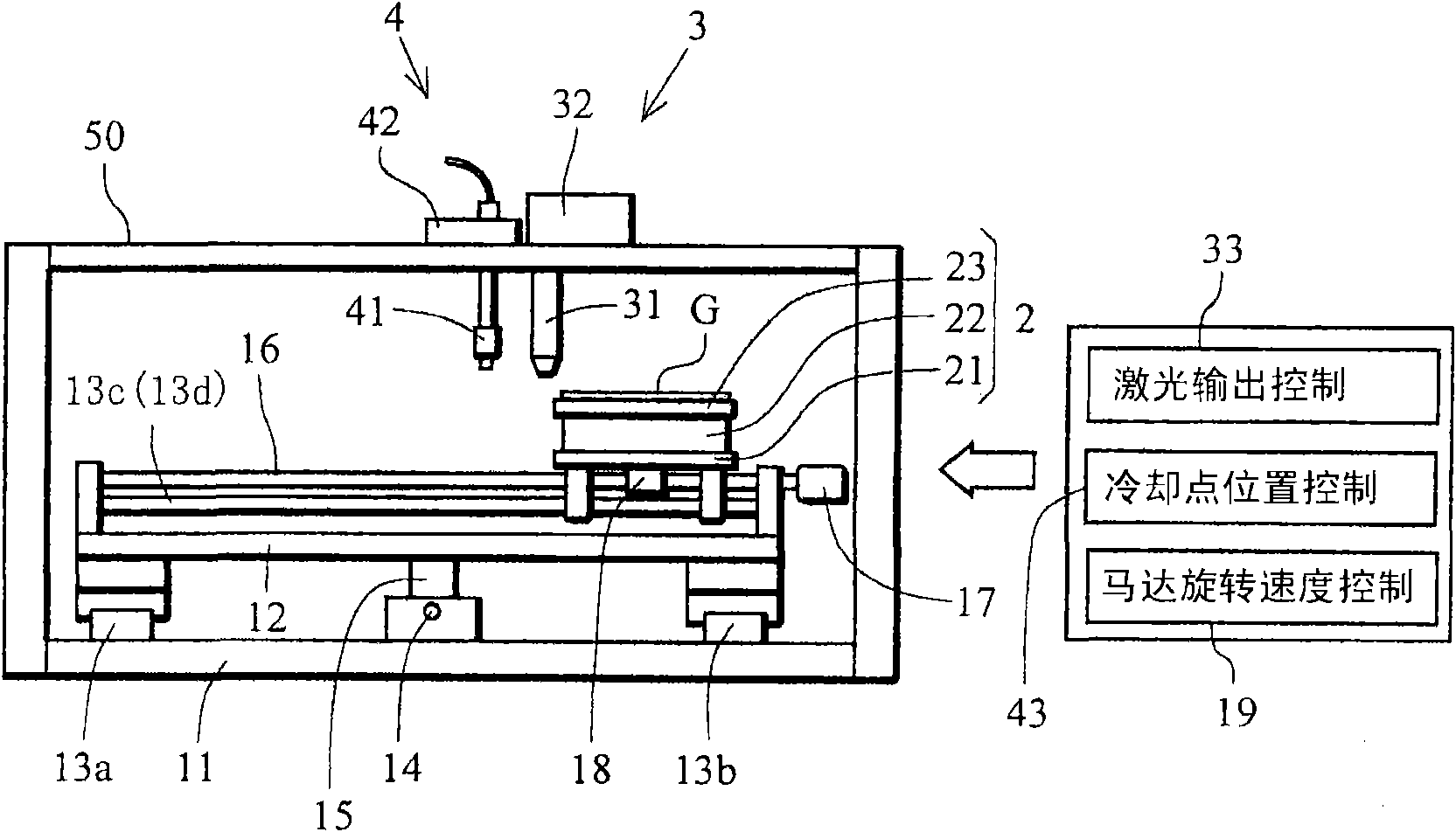

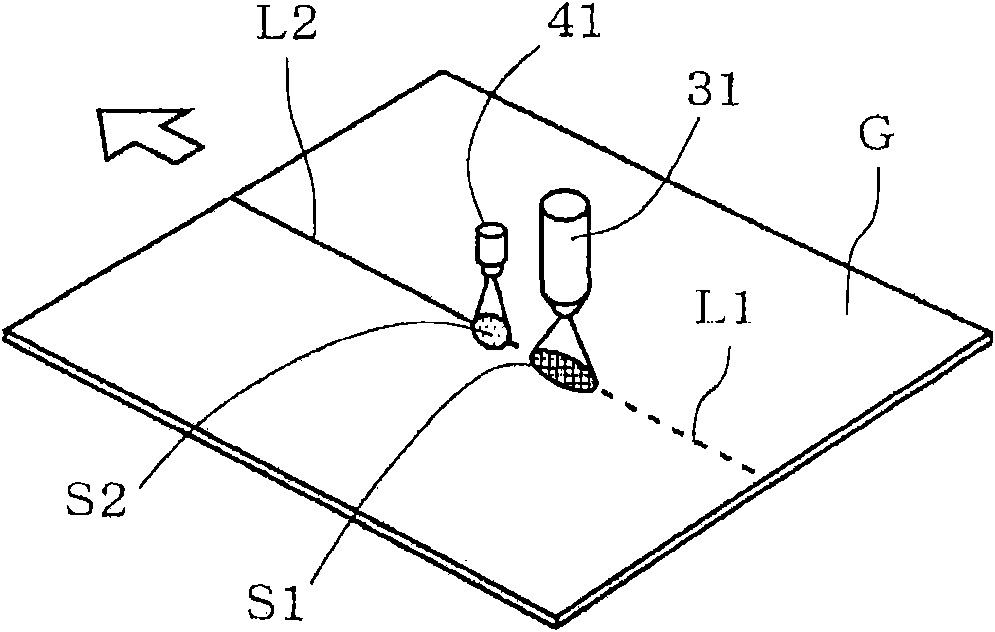

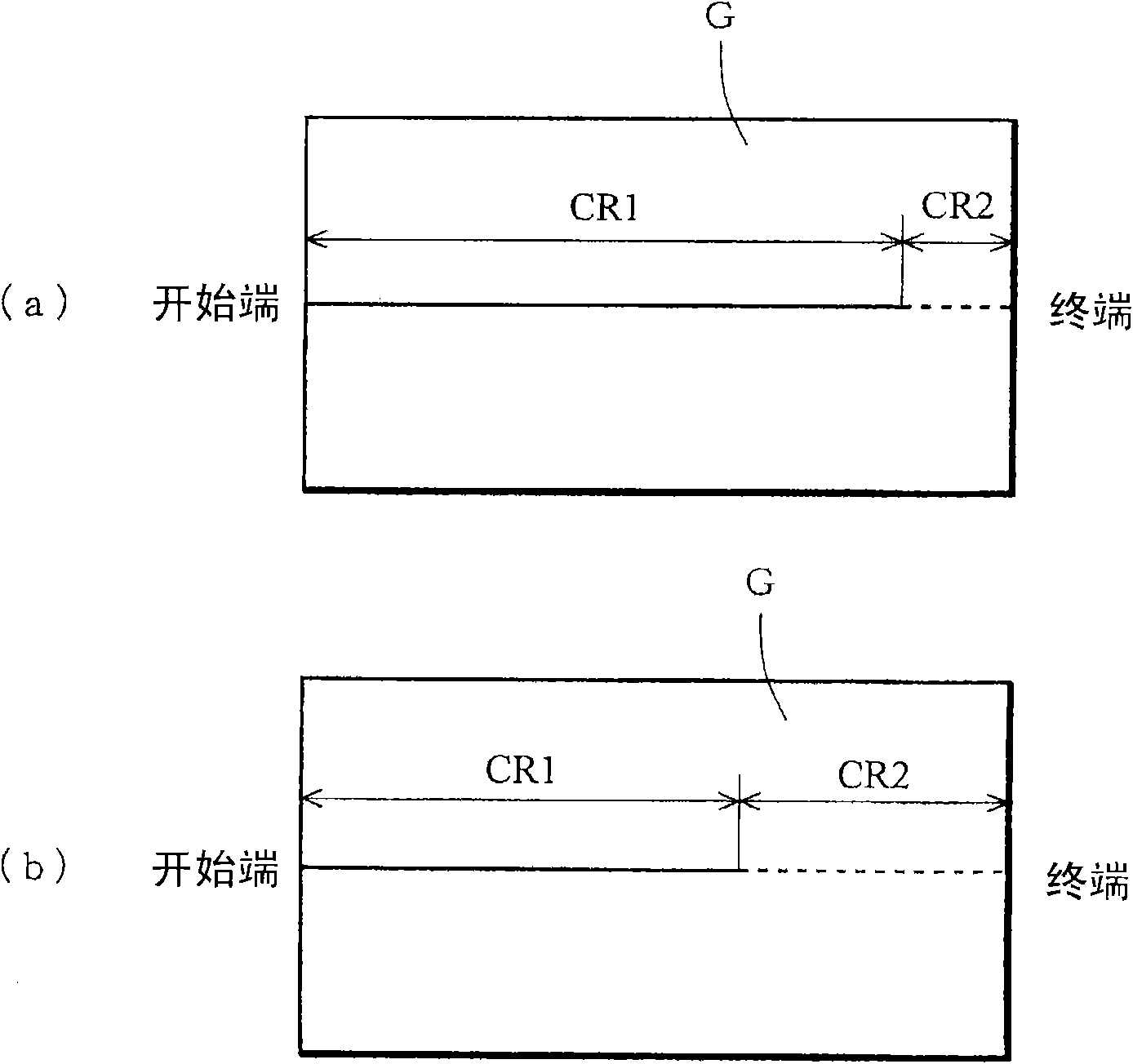

[0025] At figure 1 A schematic diagram showing an example of a cutting device capable of carrying out the cutting method of the present invention. exist figure 1 In the cutting device of the present invention, a pair of guide rails 13a, 13b are arranged in parallel at a predetermined distance on the horizontal platform 11 . Moreover, the slide table 12 which moves in the direction perpendicular to the paper surface on this pair of guide rails 13a, 13b is provided. A pillar 15 is suspended downward from the lower surface of the slide table 12 . A lead screw 14 arranged parallel to the guide rails 13a, 13b between the guide rails 13a, 13b is screwed to the support 15, and the lead screw 14 is rotated forward and reverse by a motor not shown, so that the slide table 12 moves alon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com